Method of preparing mercaptopoly asparagic acid and chitin copolymer and use

A technology of mercaptopolyaspartic acid and chitosan copolymer is applied in the field of fine chemicals of chemical engineering, which can solve the problems of limitation and poor adsorption effect, and achieve the effect of small swelling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

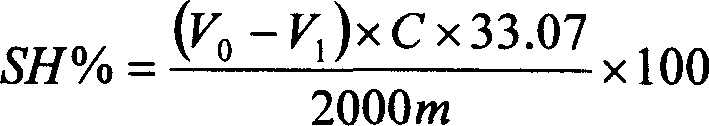

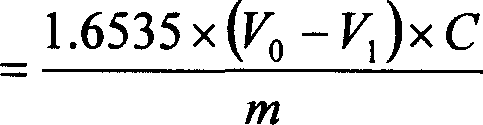

Image

Examples

Embodiment 1

[0046] Embodiment 1: use organic solvent, do not add templating agent to prepare mercaptopolyaspartic acid / chitosan copolymer, this method comprises the following steps:

[0047] (1) Preparation of polyaspartic acid having a side chain of at least one amine group. The method is to react polysuccinimide with polyamine or its hydrochloride in an organic solvent (such as dimethylformamide). Molar ratio of polyamine to polysuccinimide (according to succinimide unit): 0.05-0.5:1, reaction temperature 20-100°C, reaction time 1-10 hours. After the reaction is complete, add anhydrous methanol or anhydrous ethanol to precipitate the product, filter, and vacuum-dry the filter cake at 40-60° C. for 4 hours to obtain polyaspartic acid with amino side chains.

[0048] The raw material polysuccinimide can be obtained by traditional thermal polycondensation method, for example, obtained by high temperature polymerization of aspartic acid under catalyzed or non-catalyzed conditions, can refe...

Embodiment 2

[0058] Embodiment 2: use organic solvent, add templating agent to prepare mercapto-containing polyaspartic acid / chitosan copolymer, the method may further comprise the steps:

[0059] The basic steps are the same as in Example 1, except that a template agent is added to the solution obtained in step (2), and then subsequent operations are carried out. The template used is preferably CaCl 2 or Ca(NO 3 ) 2 , CaSO 4 , ZnCl 2 , MgCl 2 , MgSO 4 One or a mixture of two or more, or other soluble nickel salts, copper salts, iron salts, manganese salts, etc. The molar ratio of template agent to polysuccinimide (according to succinimide unit) is 0.1-1:1;

[0060] A templating agent can also be added to the chitosan solution (4). Or several templating agents are added to the chitosan solution (4), and other templating agents are added to the solution (2) of polyaspartic acid with amine side chains;

[0061] If necessary, the obtained resin can also be subjected to a release agen...

Embodiment 3

[0062] Embodiment 3: use organic solvent, do not add templating agent to prepare mercapto polyaspartic acid / chitosan copolymer, this method comprises the following steps:

[0063] (1) With the step (1) of embodiment 1, obtain the polyaspartic acid of the side chain containing at least one amine group; The mole of polyamine and polysuccinimide (according to succinimide unit) The ratio is: 0.05-0.50:1.

[0064] (2) With the step (2) of embodiment 1, obtain the aqueous solution of the polyaspartic acid that contains the side chain of an amino group at least, the mass ratio of the polyaspartic acid of band amino side chain and water is: 1 :99-99:1;

[0065] (3) Prepare chitosan solution. Dissolve chitosan in dilute acid solution. The dilute acid solution may be dilute hydrochloric acid solution, acetic acid solution, or a mixture of the two. The concentration of the dilute acid solution is 1-2% (mass fraction). The mass ratio of chitosan to 1-2% dilute acid is: 1:1-1:100;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com