Ultra-low VOC air-drying poly-aspartic paint for engineering machinery

A technology of polyaspartate and aspartate, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high surface tension, fast curing and film formation, etc., and achieve good weather resistance, good film appearance, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be further described in conjunction with the examples, and the examples are only for explanation and not intended to limit the protection scope of the present invention.

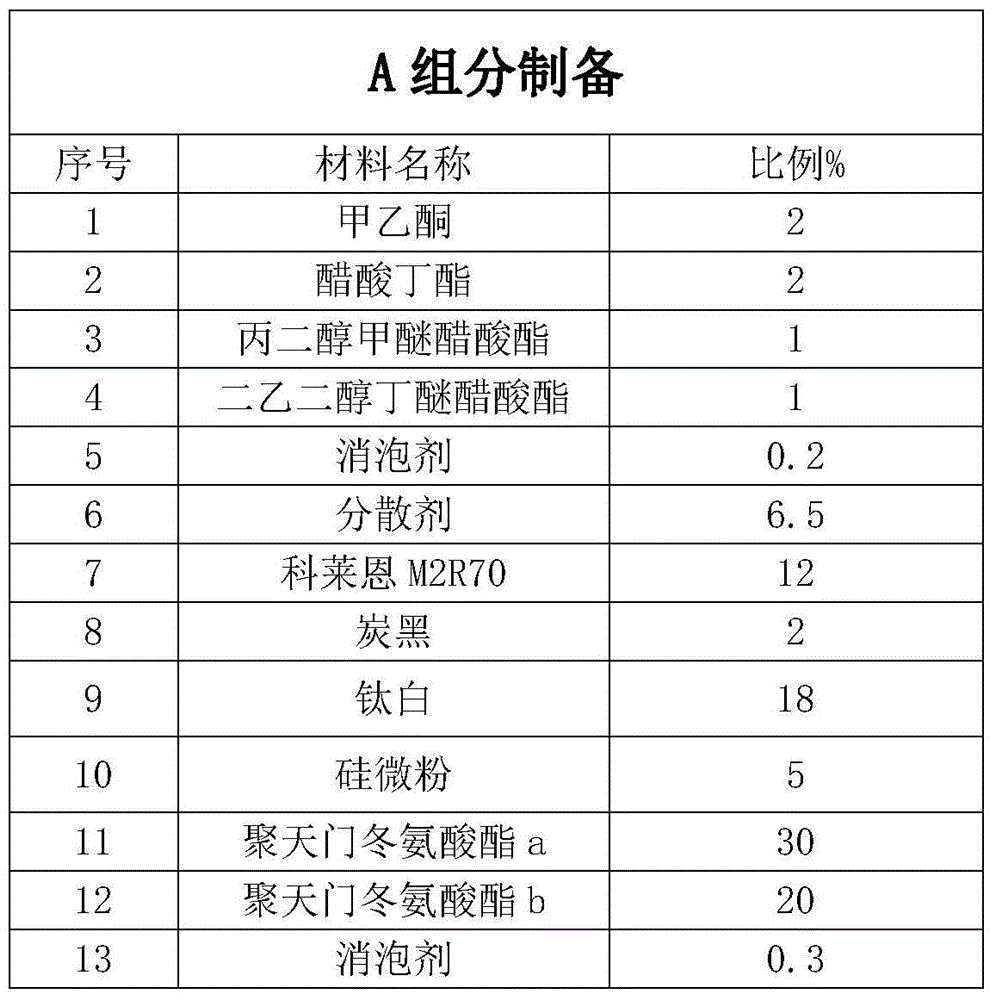

[0032]

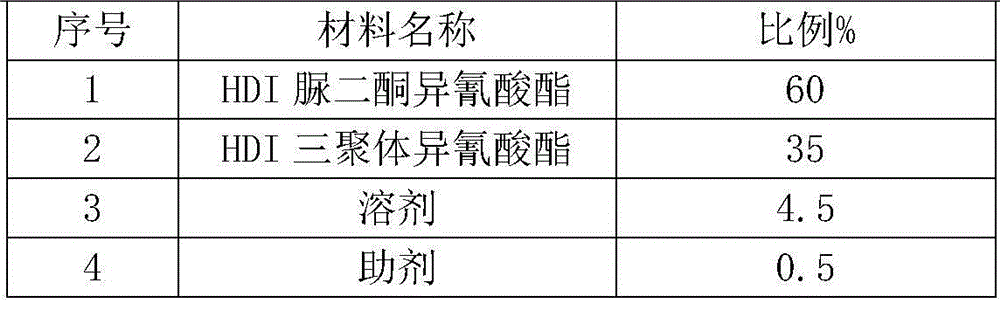

[0033]

[0034]

[0035] Preparation method: A component: Add 1-6 and stir evenly, add 7-10 under high-speed stirring, add zirconium beads to grind until the fineness is less than 10 μm, add 11-13 at a reduced speed, and mix well to obtain polyaspartic acid Ester Coating A Component. Component B: Add 1-4 and stir evenly to prepare component B of polyaspartic acid ester coating.

[0036] The performance test of the paint is tested according to the test method specified in the corresponding national standard, and the performance is as follows:

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com