Rare earth complex modified cold-resistant fluororubber gross rubber and preparation method thereof

A rare earth compound and fluororubber technology, applied in the field of special rubber, can solve the problems of poor cold resistance and difficult molding of fluororubber, and achieve the effects of improving cold resistance, low cost and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

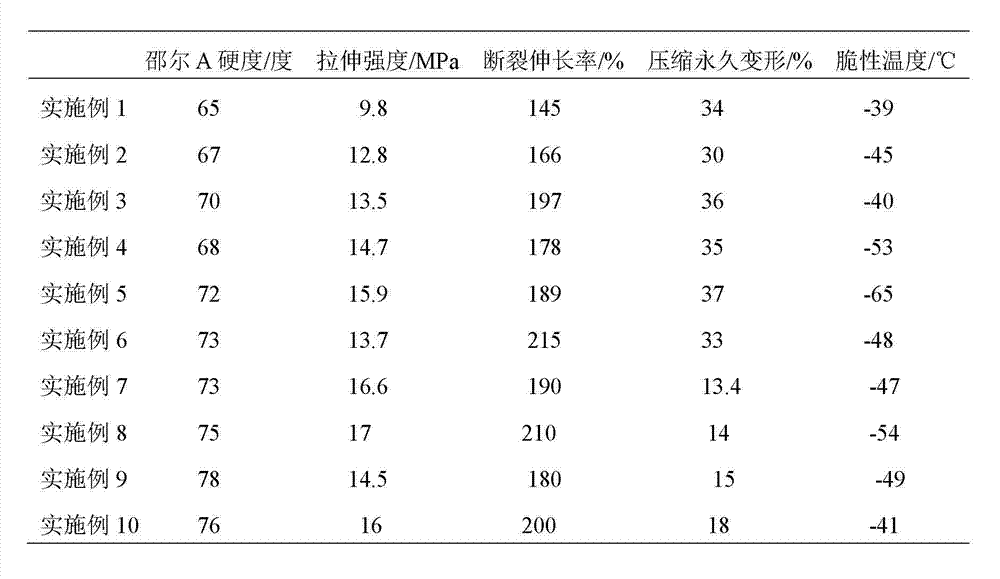

Examples

Embodiment 1

[0026] The content of the raw material components in parts by weight is: 100 parts of binary fluorinated phosphazene rubber, 0.5 parts of samarium 8-hydroxyquinoline, 2 parts of activated magnesium oxide, 4 parts of calcium hydroxide, 5 parts of white carbon black, and 1 part of DCP , 0.3 copies of TAIC.

Embodiment 2

[0028] The content of the raw material components in parts by weight is: 100 parts of binary fluorinated phosphazene rubber, 25 parts of samarium 8-hydroxyquinoline, 3 parts of activated magnesium oxide, 6 parts of calcium hydroxide, 25 parts of white carbon black, and 1.5 parts of DCP , 0.5 copies of TAIC.

Embodiment 3

[0030] The content of the raw material components in parts by weight is: 100 parts of binary fluorinated phosphazene rubber, 38 parts of samarium 8-hydroxyquinoline, 3 parts of activated magnesium oxide, 6 parts of calcium hydroxide, 45 parts of white carbon black, and 3 parts of DCP , 0.8 copies of TAIC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com