Short carbon fiber-staple glass fiber hybrid reinforced rubber-based sealing composite material and preparation technique thereof

A technology of short glass fibers and reinforced rubber, which is applied in the field of reinforced rubber-based sealing composite materials and its preparation, and can solve the problems of incomplete satisfaction, no advantage in price, and low service temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

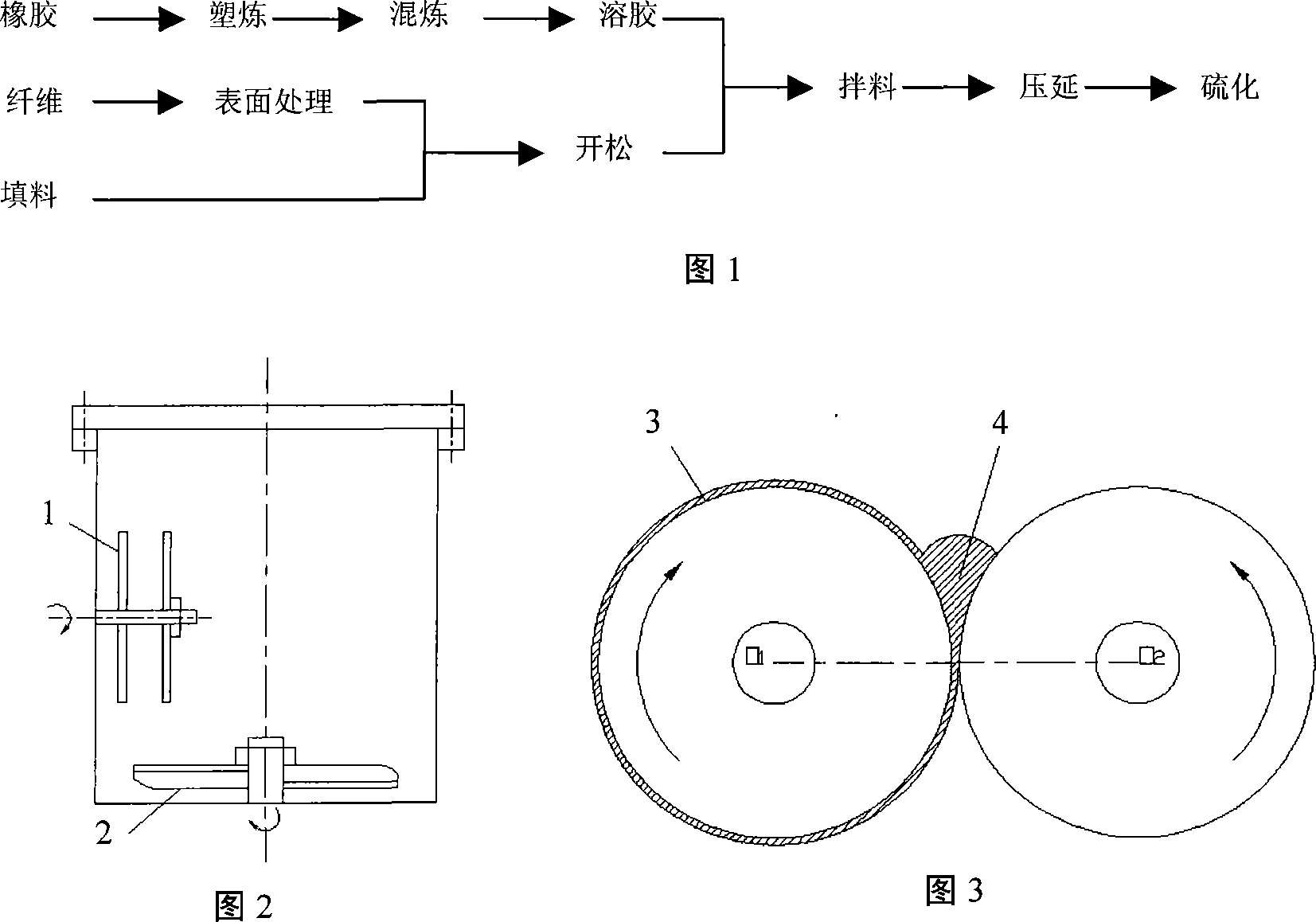

Method used

Image

Examples

Embodiment 1

[0046] NAFC material composition ratio 1 (as shown in the table below):

[0047] composition

Percent content / (wt)%

composition

Percent content / (wt)%

NBR-26

carbon fiber

meerschaum

16

8

12

42.8

0.3

fill in

Material

Kaolin

white carbon black

ultrafine graphite

5.8

2.9

2.1

1.5

5

Accelerator TT

accelerator DM

0.1

0.2

0.15

0.4

Antiaging agent (4010NA)

Phenolic Resin

0.5

2

0.25

[0048] Main preparation process parameters:

[0049] Mixing time: 20min

[0050] Cutting knife speed: 3000r / min to 1200r / min

[0051] Stirring speed: 300r / min to 90r / min

[0052] Vulcanization temperature: 160°C

[0053] Vulcanization pressure: 16MPa ...

Embodiment 2

[0060] NAFC material composition ratio 2 (see table below):

[0061] composition

Percent content / (wt)%

composition

Percent content / (wt)%

NBR-26

carbon fiber

meerschaum

10

8

12

10

35.9

0.4

fill in

Material

Kaolin

white carbon black

5.8

2.9

2.5

2.0

6.0

Accelerator TT

accelerator DM

0.15

0.25

0.2

0.5

Antiaging agent (4010NA)

Phenolic Resin

0.6

2.5

0.3

[0062] Main preparation process parameters:

[0063] Mixing time: 15min

[0064] Cutting knife speed: 3000r / min to 1200r / min

[0065] Stirring speed: 300r / min to 90r / min

[0066] Vulcaniza...

Embodiment 3

[0074] NAFC material composition ratio 3 (as shown in the table below):

[0075] composition

Percent content / (wt)%

composition

Percent content / (wt)%

NBR-26

carbon fiber

glass fiber

meerschaum

13

5

15

48.8

0.2

fill in

Material

Kaolin

white carbon black

5.5

2.5

1.8

1.2

4.0

Accelerator TT

accelerator DM

0.1

0.1

0.1

0.3

Antiaging agent (4010NA)

Phenolic Resin

0.4

1.8

0.2

[0076] Main preparation process parameters:

[0077] Mixing time: 15min

[0078] Cutting knife speed: 3000r / min to 1500r / min

[0079] Stirring speed: 200r / min to 100r / min

[0080] Vulcanization temperature: 145°C

[0081] Vulcani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com