Sheet medium separating mechanism and sheet medium treatment mechanism

A thin sheet medium and separation mechanism technology, applied in the direction of thin material processing, pile separation, object separation, etc., can solve the problems of poor medium adaptability, inability to adapt to separate different types of media, and medium separation failure, etc., to achieve strong medium adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

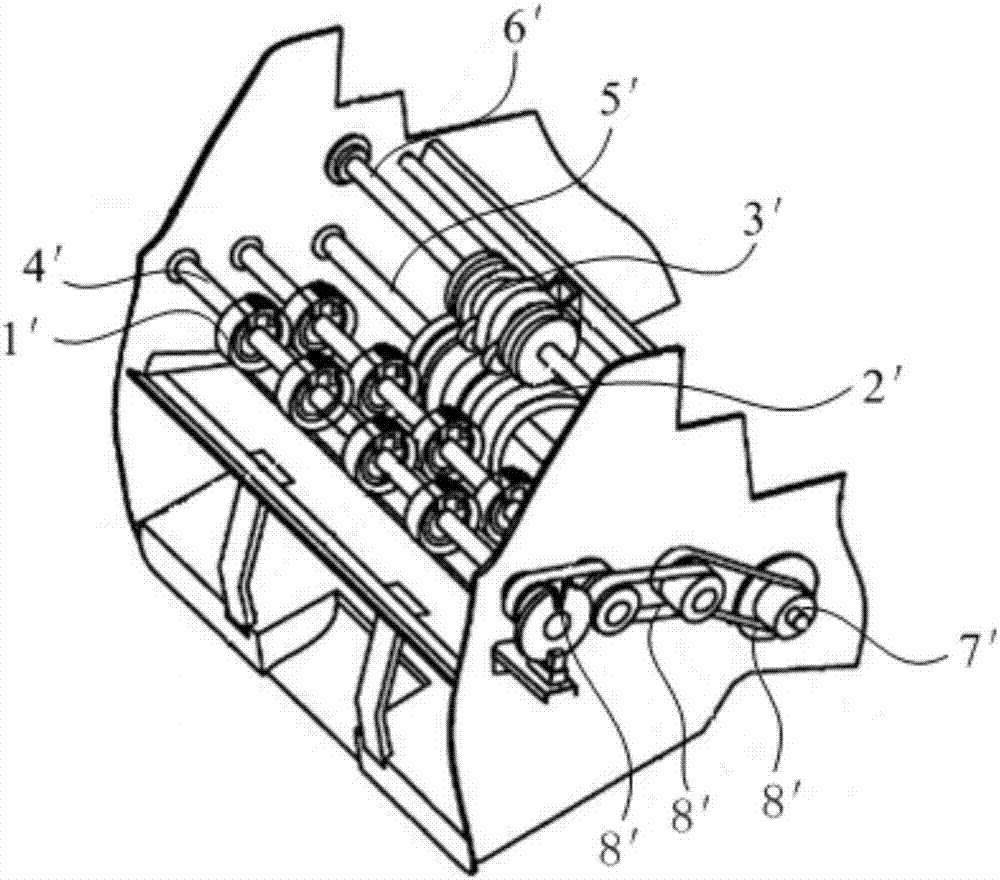

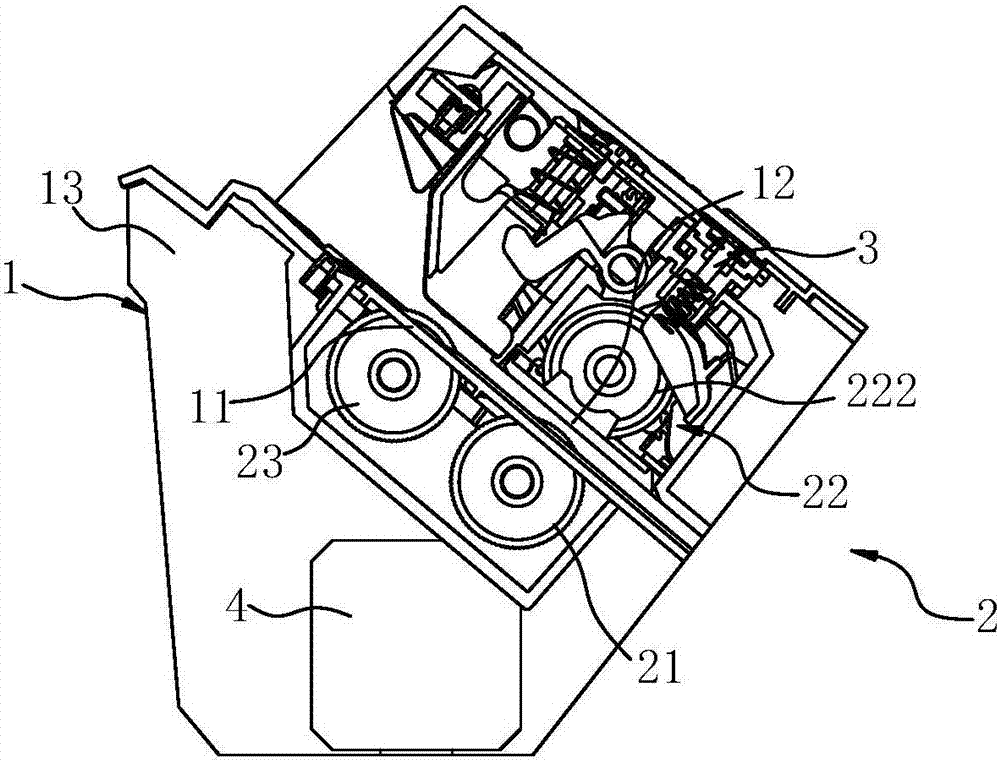

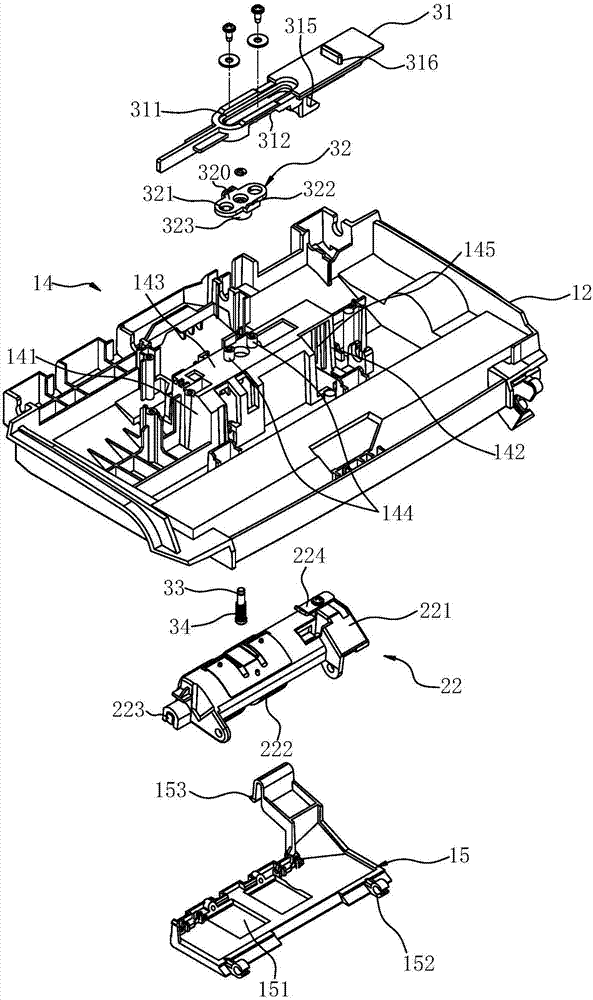

[0040] Such as Figure 2 to 7 As shown, the embodiment of the present invention provides a sheet-type medium separation mechanism, which includes a frame 1, a separation assembly 2 and an adjustment assembly 3. The separation assembly 2 includes fixed rollers arranged on both sides of the conveying channel of the frame 1. 21 and floating roller assembly 22. The floating roller assembly 22 includes a floating roller 222. The fixed roller 21 and the floating roller 222 are arranged oppositely. The floating roller assembly 22 is movably arranged in the frame 1 and can move along the height direction of the conveying channel. 3 abuts on the floating roller assembly 22, and the adjusting assembly 3 is used to adjust the pressure exerted by the floating roller 222 on the fixed roller 21.

[0041] Specific, such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com