Preparation method for UV-curing self-healing polyurethane based on furan-maleimide structure

A technology of maleimide and ultraviolet light, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as repairing environmental pollution, difficult degradation and repair of polymer networks, and achieves reduced life cycle costs and excellent physical properties. Performance, safety improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

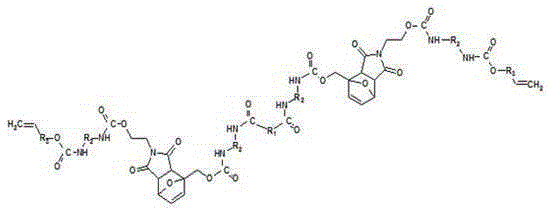

[0029] This example illustrates a preparation method 1 of a furan-maleimide-based UV-curable self-healing polyurethane provided by the present invention;

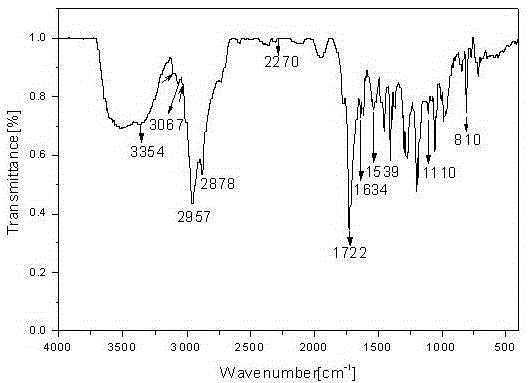

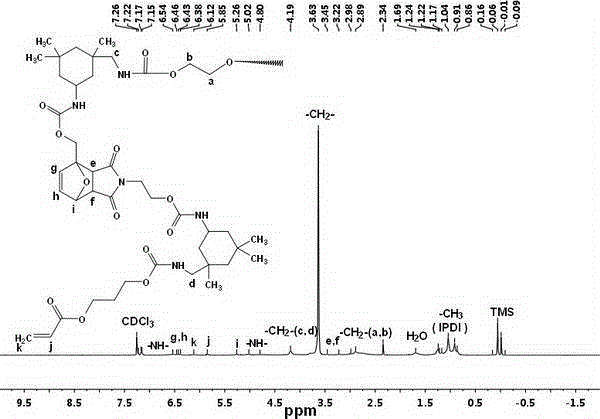

[0030] (1) At room temperature, slowly add 2.4 mol of furan to 0.4 mol of maleic anhydride dissolved in acetone, stir rapidly to disperse evenly, react for 24 hours, filter with suction, wash with a small amount of ether, filter, filter The cake was dried to obtain intermediate 1; 0.2 mol of intermediate 1 was dissolved in absolute ethanol to form solution 1, 0.2 mol of ethanolamine dissolved in absolute ethanol and 0.2 mol of triethylamine were prepared into solution 2, under nitrogen protection, Maintain the temperature at 0-2°C, slowly drop solution 2 into solution 1, then steadily increase the temperature to 80°C, reflux for 4 hours, then cool to room temperature, stand overnight, precipitate out, filter, and the filtrate is decompressed at 50°C Concentrate under low temperature, cool to room temperature overnight to pr...

Embodiment 2

[0034] This example illustrates the preparation method 2 of a UV-curable self-healing polyurethane based on a furan-maleimide structure provided by the present invention;

[0035](1) At room temperature, slowly add 2.0 mol of furan to 0.4 mol of maleic anhydride dissolved in toluene, stir rapidly to disperse evenly, react for 18 hours, filter with suction, wash with a small amount of ether, filter, filter The cake was dried to obtain intermediate 1; 0.2 mol of intermediate 1 was dissolved in absolute ethanol to form solution 1, and 0.24 mol of ethanolamine dissolved in absolute ethanol and 0.26 mol of triethylamine were prepared into solution 2, under nitrogen protection, Keep the temperature at 0-2°C, slowly drop solution 2 into solution 1, then steadily raise the temperature to 90°C, reflux for 3 hours, then cool to room temperature, stand overnight, precipitate precipitate, filter, and the filtrate is decompressed at 45°C Concentrate under low temperature, cool to room temp...

Embodiment 3

[0039] This example illustrates the preparation method 3 of a UV-curable self-healing polyurethane based on a furan-maleimide structure provided by the present invention;

[0040] (1) At room temperature, slowly add 1.6 mol of furan to 0.4 mol of maleic anhydride dissolved in toluene, stir rapidly to disperse evenly, react for 16 hours, filter with suction, wash with a small amount of ether, filter, filter The cake was dried to obtain intermediate 1; 0.2 mol of intermediate 1 was dissolved in absolute ethanol to form solution 1, 0.2 mol of ethanolamine dissolved in absolute ethanol and 0.2 mol of triethylamine were prepared into solution 2, under nitrogen protection, Maintain the temperature at 0-2°C, slowly drop solution 2 into solution 1, then steadily raise the temperature to 85°C, reflux for 3.5 hours, then cool to room temperature, stand overnight, precipitate precipitate, filter, and the filtrate is decompressed at 50°C Concentrate under low temperature, cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com