Preparation method of epoxy/polyaniline composite base-material for anticorrosion paint

An anti-corrosion coating, polyaniline technology, applied in anti-corrosion coatings and other directions, can solve the problems of high price, complex process, environmental pollution, etc., and achieve the effects of low cost, simple process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

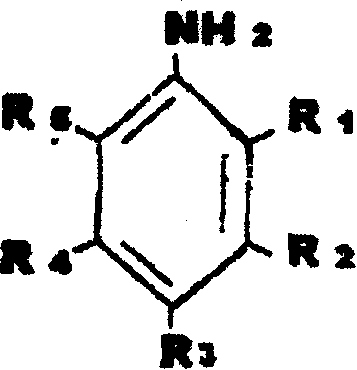

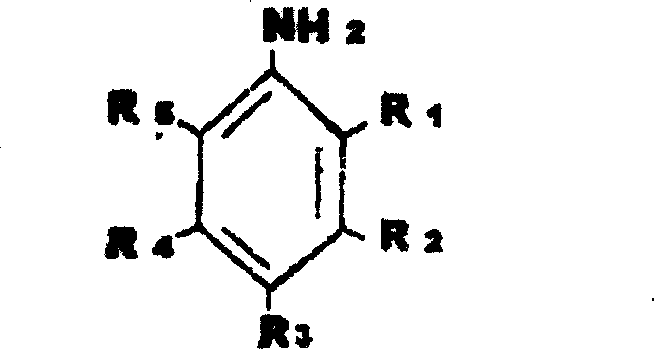

Image

Examples

Embodiment 1

[0024] Weigh 10g of epoxy resin into a 50ml beaker, heat to 50-60°C, stir evenly, cool to 15-25°C, add 2g of aniline monomer, adjust the pH of the system to 1 with hydrochloric acid, add 2g of persulfuric acid dropwise 12ml of ammonium solution, reacted for 2.5h, allowed to stand for stratification, and poured out the water layer to obtain the epoxy / polyaniline composite base material. Then add 3.5g of low-molecular polyamide curing agent to the composite base material, stir evenly, and then coat the film on the treated steel plate. First, put the coated film at room temperature to air for a period of time, and then put it into the oven. In drying at 60°C for a period of time, an epoxy resin / polyaniline composite film can be obtained.

Embodiment 2~3

[0031] Change the consumption of aniline monomer, the consumption of embodiment 2 aniline monomer is 1g, the consumption of embodiment 3 aniline monomer is 1.5g, other conditions are the same as embodiment 1. The test results of the corrosion potential of the composite film are shown in Table 2:

[0032] Example 2 Example 3

Embodiment 4~5

[0034] Change the consumption of oxidant, the consumption of embodiment 4 oxidant is 1.8g, the consumption of embodiment 5 oxidant is 2.5g, and other conditions are identical with embodiment 1. The measurement results of the corrosion potential of the composite film are shown in Table 3:

[0035] Example 4 Example 5

[0036] Example 1 2 3 4 5 Comparative example

[0037] As can be seen from Table 4, the preparation method of the epoxy / polyaniline composite base material for anti-corrosion coatings described in the present invention is not only simple in process, low in cost, and environmentally friendly, but also compared with commercial polyaniline currently on the market, the The anti-corrosion performance has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com