Aqueous composite adhesive and preparation method and use thereof

A composite adhesive and adhesive technology, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of high cost and uncompetitive water-based adhesives, and achieve improved water resistance and high composite strength , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

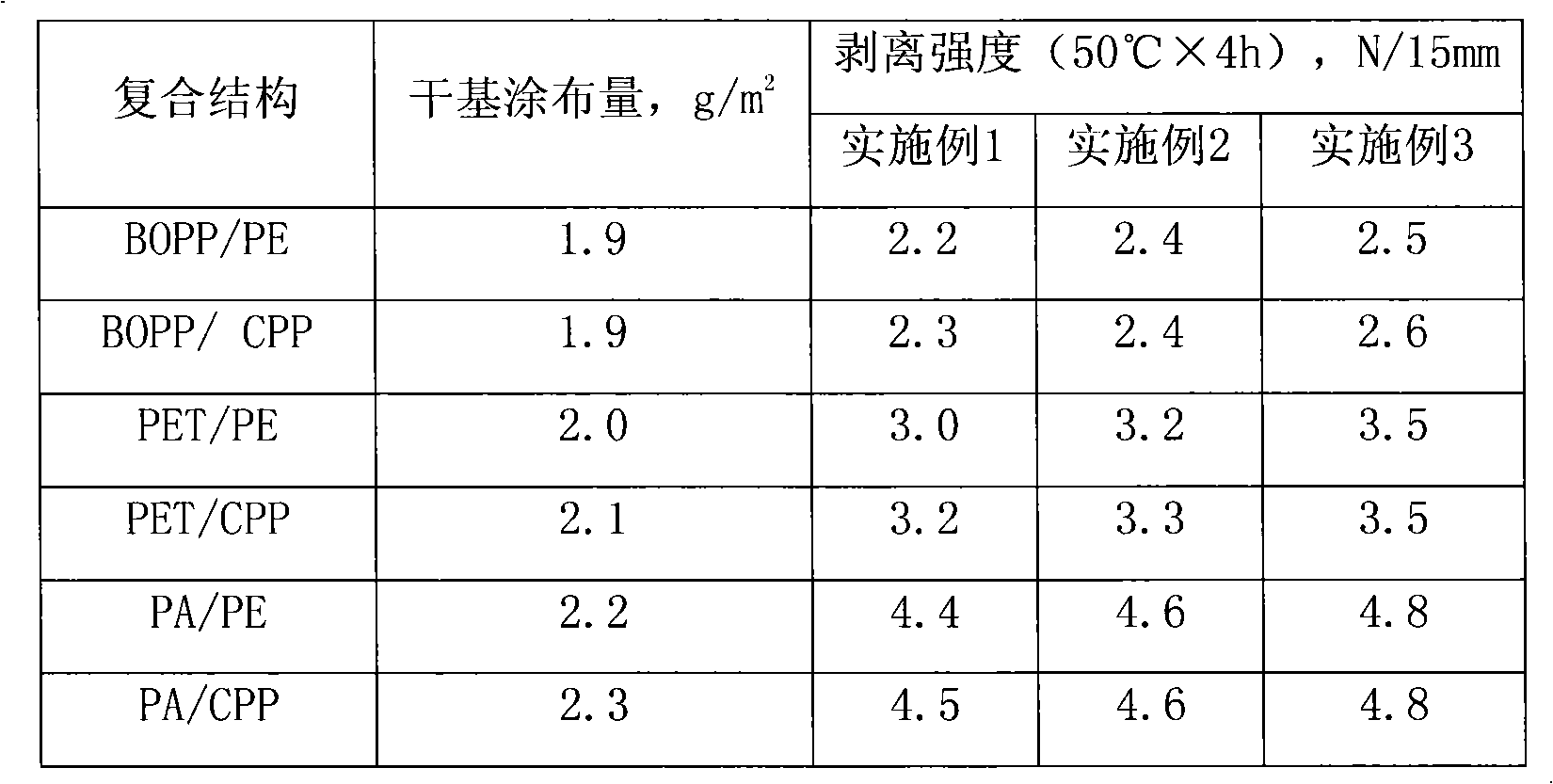

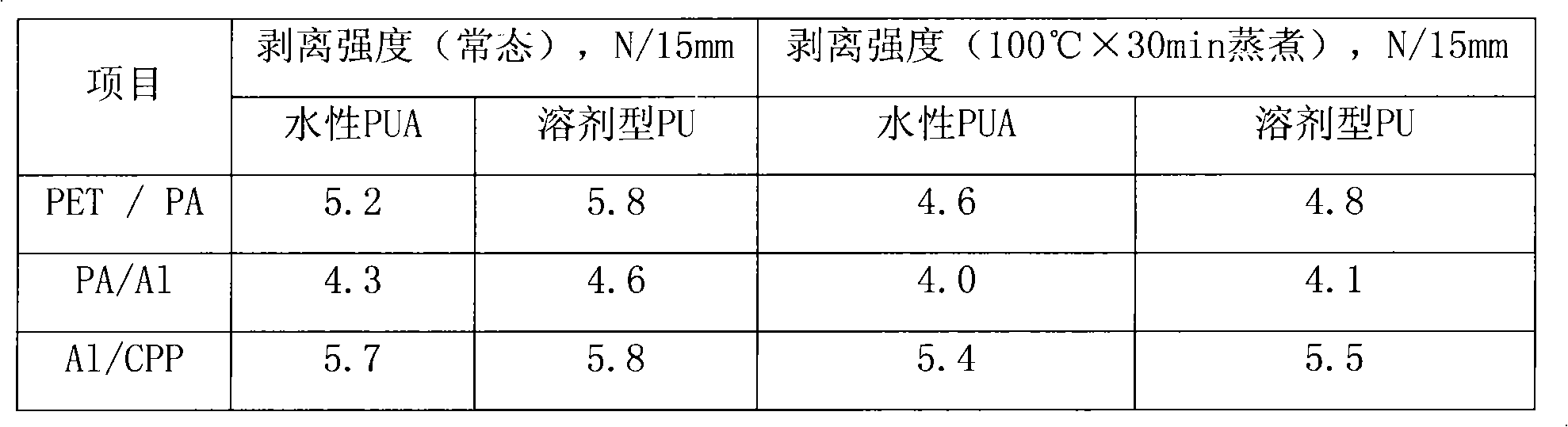

Examples

Embodiment 1

[0035] Embodiments of the present invention provide a water-based composite adhesive that is economical, affordable, and excellent in performance. The adhesive is a polyurethane / acrylate (PUA) composite emulsion formed by chemically copolymerizing polyurethane and polyacrylate, and its solid content is 30-50%, wherein polyurethane accounts for 5-20% of the total weight of the composite emulsion, polyacrylate accounts for 25-45% of the total weight of the composite emulsion, and water accounts for 50-70% of the total weight of the composite emulsion.

[0036] The preparation method of this aqueous composite adhesive comprises the following steps:

[0037] a. Preparation of water-based polyurethane PU emulsion: dehydrate the macromolecular diol at 110°C and vacuum 0.02MPa for 1 hour, then lower it to room temperature, add diisocyanate and a small amount of organotin catalyst and react at 60-80°C for 2-4 hours , then lower the temperature to 60°C and add a small molecule chain ex...

Embodiment 2

[0057] This embodiment provides a method for preparing a water-based composite adhesive. The prepared adhesive can be used to prepare composite film flexible packaging. The method specifically includes the following steps:

[0058] a. Preparation of water-based PU emulsion: get 180g polyether diol (Mn=2000), dehydrate at 110°C and vacuum 0.02MPa for 1h, then drop to room temperature, add 68g TDI and 0.02g dibutyltin dilaurate catalyst, React at 60-80°C for 2-4h, then cool down to 60°C, add 6g BDO and 16gDMPA, continue to react for 3-6h to obtain PU prepolymer, add 100g of ethyl acrylate and butyl acrylate mixture (EA:BA =3:1, weight ratio) as a solvent to dilute the prepared PU prepolymer, then add 25g hydroxyethyl acrylate, continue the reaction for 2-4h, then drop to room temperature and add 11g triethylamine (TEA) to neutralize, Add deionized water to disperse under high shear force to obtain water-based polyurethane emulsion;

[0059] b. Preparation of water-based PUA emu...

Embodiment 3

[0062] The present embodiment provides a kind of preparation method of water-based composite adhesive, and this method specifically comprises the following steps:

[0063] a. Preparation of water-based PU emulsion: Take 160g of polyether diol (Mn=2000) and 40g of polyester diol (Mn=2000), dehydrate at 110°C for 1h under a vacuum of 0.02MPa, then cool down to room temperature, add 86g of TDI React with 0.03g dibutyltin dilaurate catalyst at 60-80°C for 2-4h, then cool down to 60°C, add 7gBDO and 19gDMPA, continue to react for 3-6h to obtain PU prepolymer, add 100g methyl acrylate And the mixture of butyl acrylate (MA: BA=1: 1, weight ratio) is used as solvent to dilute prepolymer, then add 30g hydroxypropyl acrylate, continue to react for 2~4h, drop to room temperature and add 12g triethylamine ( TEA) neutralization, adding deionized water to disperse water-based polyurethane emulsion under the action of high shear force;

[0064]b. Preparation of water-based PUA emulsion: Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com