Paint containing waterborne alkyd resin and preparation method of paint

A technology of water-based alkyd resin and water-based acrylic, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of low solid content in construction, difficult to achieve, and discounted stability, so as to reduce potential safety hazards, The effect of uniform and dense film formation and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

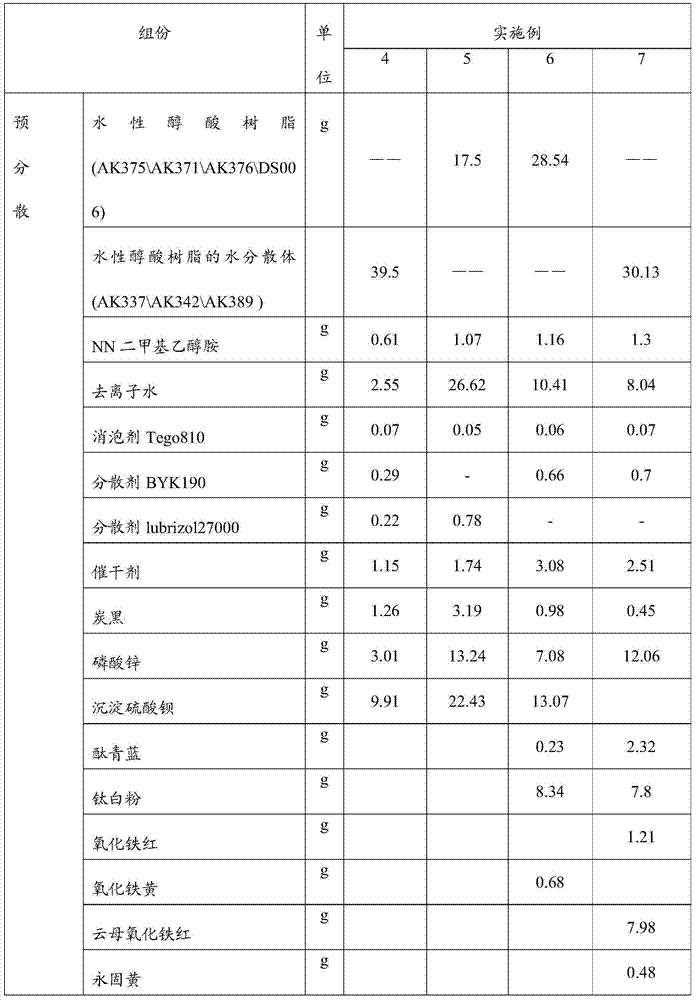

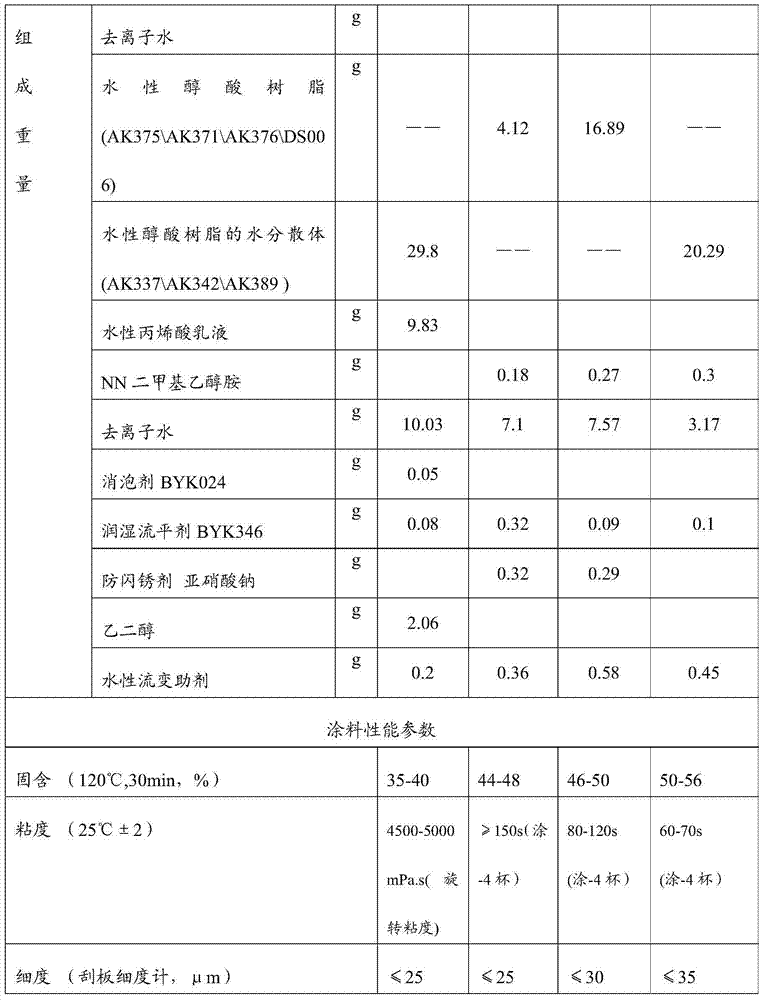

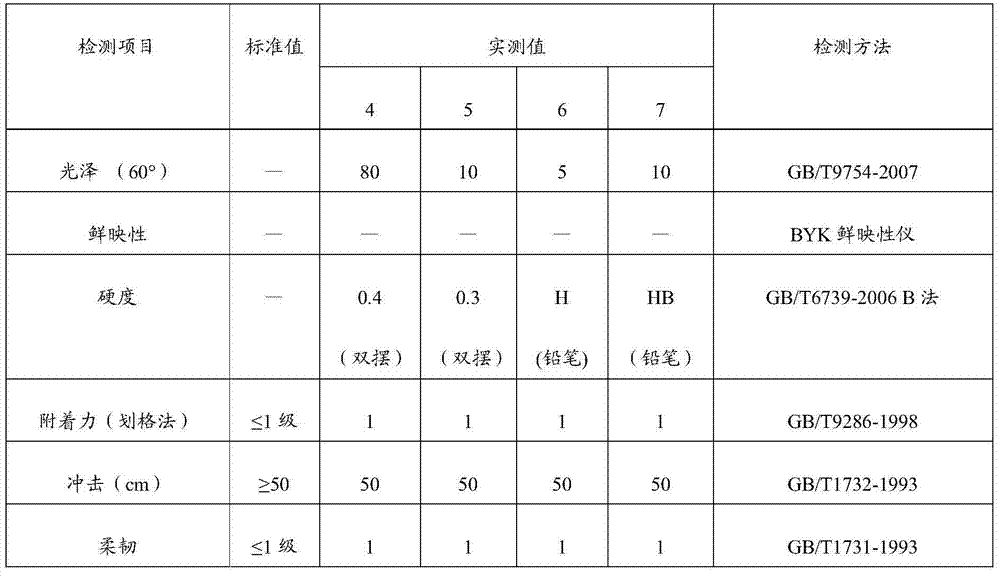

Examples

Embodiment 1

[0036]Add 22 parts of trimethylolpropane, 8 parts of benzoic acid, and 0.01 part of organotin catalyst into the reaction flask, raise the temperature from 170°C to 230°C in 3 hours, keep the column temperature below 105°C, and react until the acid value is less than 3mgKOH / g, add 22 parts of dehydrated ricinoleic acid, 17 parts of isophthalic acid, and 0.02 parts of organotin catalyst, gradually raise the temperature to 230°C, control the column temperature below 105°C, react until the acid value is less than 5mgKOH / g, and cool down to 170°C, Add 6.5 parts of trimellitic anhydride, 0.01 part of catalyst, react at 180°C until the acid value is 45-50mgKOH / g, cool down to 160°C, add 21 parts of ethylene glycol butyl ether, 1.4 parts of butanol, and stir evenly to obtain a water-based water-based alkyd resin. The acid value of the resin is about 33mgKOH / g, and the solid content is about 75%. According to the dilution ratio of 1:1, it is diluted with propylene glycol methyl ether ...

Embodiment 2

[0038] Put 18 parts of trimethylolpropane and 1.1 parts of benzoic acid into the reaction bottle, raise the temperature from 170°C to 230°C in 3 hours, keep the column temperature below 105°C, react until the acid value is less than 3mgKOH / g, add soyoleic acid 24.5 parts, 3.8 parts of oleic acid, 17 parts of phthalic anhydride, gradually raise the temperature to 230°C, control the column temperature below 105°C, react until the acid value is less than 5mgKOH / g, cool down to 170°C, add 4.9 parts of trimellitic anhydride, and react to the acid value at 180°C 45-50mgKOH / g, lower the temperature to 160°C, add 14 parts of ethylene glycol ether and 8 parts of isopropanol, stir well to obtain a water-based alkyd resin, in which the acid value of the resin is about 33mgKOH / g, and the solid content is about 73%. . According to the dilution ratio of 1:1, dilute with propylene glycol methyl ether to obtain a viscosity of 50-100cp, add 100 parts of the obtained resin, add 5 parts of neutr...

Embodiment 3

[0040] Add 21 parts of trimethylolpropane, 7.7 parts of benzoic acid, and 0.01 part of organotin catalyst into the reaction flask, raise the temperature from 170°C to 230°C in 3 hours, keep the column temperature below 105°C, and react until the acid value is less than 3mgKOH / g, add 3 parts of dehydrated ricinoleic acid, 18 parts of linolenic acid, 17 parts of isophthalic acid, 0.02 parts of organotin catalyst, gradually raise the temperature to 230°C, control the column temperature below 105°C, and react until the acid value is less than 5mgKOH / g , lower the temperature to 170°C, add 5.9 parts of trimellitic anhydride, 0.01 part of catalyst, react at 180°C until the acid value is 45-50 mgKOH / g, lower the temperature to 160°C, add 10 parts of ethylene glycol butyl ether, 15 parts of butanol, and stir evenly to obtain Water-based alkyd resin, the acid value of the resin is about 35mgKOH / g, and the solid content is about 75%. According to the dilution ratio of 1:1, it is dilute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com