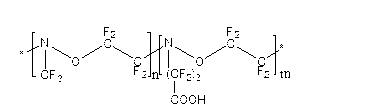

Carboxynitrosofluoroelastomer composition with low permanent deformation rate

A technology of carboxynitroso fluorine and rubber composition is applied in the field of rubber sealing parts, which can solve the problems of application limitation, compression permanent deformation and tearing permanent deformation rate, etc., and achieves convenient source, low toxicity, and high rubber mixing. Process safety and operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

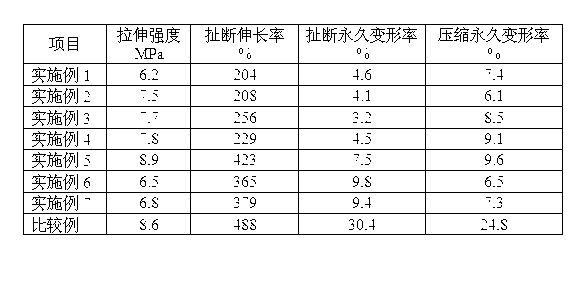

Embodiment 1

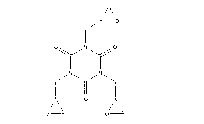

[0026] Add 100 parts of CNR raw rubber, 25 parts of fumed white carbon black, 2.5 parts of methyl silicone oil, 1.2 parts of fluorinated graphite, 1.5 parts of palm wax, and 1.2 parts of TGIC into an open mill and knead evenly. Molding vulcanization on the vulcanizing machine under the condition of 145°C×15MPa for 40min, and then secondary vulcanization in 180°C hot air flow for 24h to obtain the sealed parts.

Embodiment 2

[0028] Add 100 parts of CNR raw rubber, 30 parts of fumed silica, 2 parts of methyl silicone oil, 1.5 parts of fluorinated graphite, 2 parts of polyethylene glycol, 2 parts of basic copper sulfate, and 1.8 parts of TGIC into the open mill Mix evenly, prefabricate, mold and vulcanize in a flat vulcanizing machine at 165°C×15MPa for 50 minutes, and then perform secondary vulcanization in 180°C hot air flow for 24 hours to obtain a sealed product.

Embodiment 3

[0030] Put 100 parts of CNR raw rubber, 30 parts of fumed white carbon black, 2.5 parts of methyl silicone oil, 1.5 parts of fluorinated graphite, 1 part of basic chromium trifluoroacetate, and 1.5 parts of TGIC into an open mill and knead evenly. Molding, molding and vulcanizing on a flat vulcanizing machine at 145°C × 15MPa for 40 minutes, and then secondary vulcanization in 180°C hot air flow for 24 hours to obtain a sealed part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com