Fluororubber compound and preparation method thereof

A technology of fluororubber raw rubber and mixed rubber, which is applied in the rubber field, can solve the problems of only mentioning, not developing seal products, and not pointing out, and achieve good low-temperature performance, easy promotion, and increased dosage

Active Publication Date: 2018-03-09

ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Chinese patent CN104356562A is a kind of fluorine rubber compound rubber and its preparation method. A kind of compound rubber composed of a vulcanizing agent, a vulcanization aid and a low-temperature modifier and its preparation method. The patent only mentions the consideration of low-temperature performance and fuel resistance performance, and does not point out that it has both high-temperature performance and new-type fuel performance.

[0005] So far, in the prior art, there has not been developed a sealing product that can replace the imported fluororubber compound as a higher requirement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

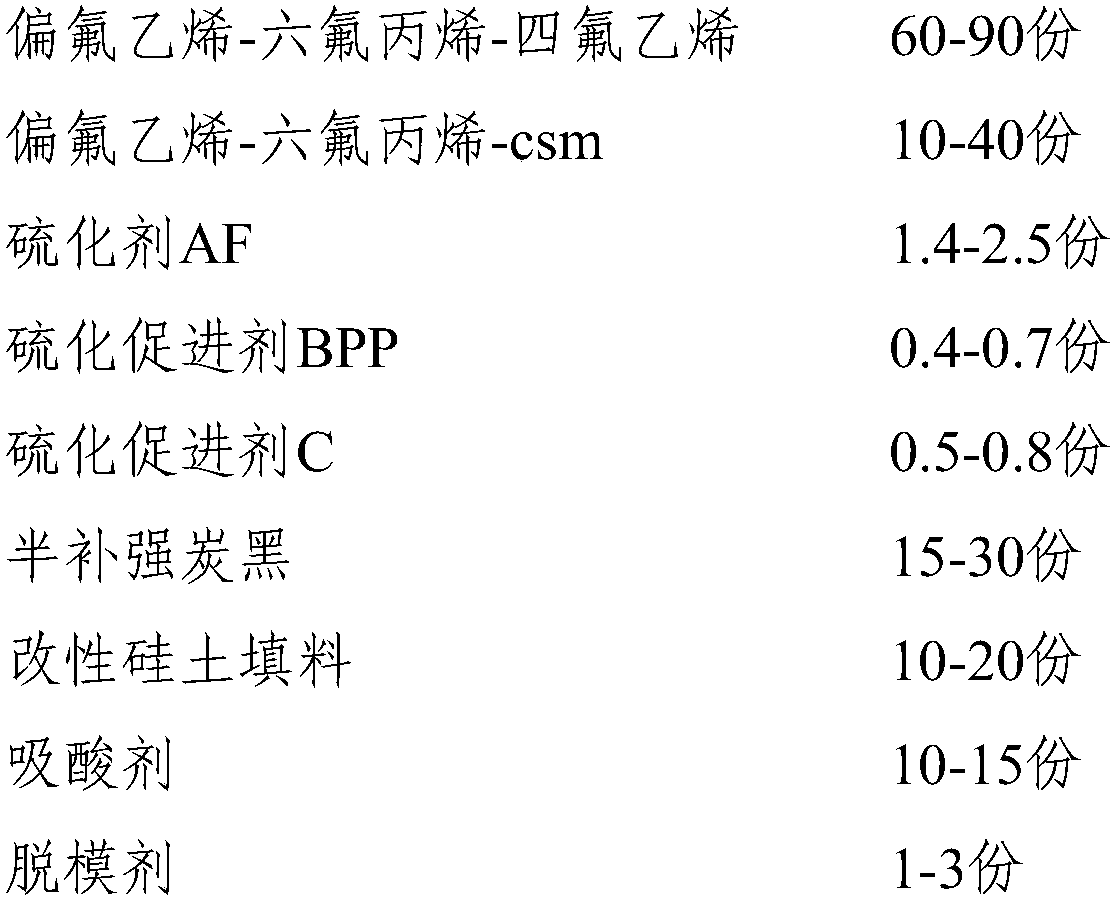

[0059] A fluororubber compound prepared from the following components:

[0060]

[0061]

Embodiment 2

[0063] A fluororubber compound prepared from the following components:

[0064]

Embodiment 3

[0066] A fluororubber compound prepared from the following components:

[0067]

[0068]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the field of rubber, in particular to a fluororubber compound. The fluororubber compound is prepared from the following raw material components in parts by weight: 100 parts of raw fluororubber, 15 to 30 parts of carbon black filler, 10 to 20 parts of modified silica filler and 2.3 to 4 parts of vulcanizing agent, wherein the fluororubber is a mixture of ternary raw rubberand binary raw rubber; the ternary raw rubber is vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene or vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene-csm; the binary raw rubberis vinylidene fluoride-hexafluoropropylene or vinylidene fluoride-hexafluoropropylene-csm. The compound has wider temperature tolerant range and good tolerance to novel fuel or additive, and can be widely applied to sealing products for automobiles, spaceflight, chemical machines and the like.

Description

technical field [0001] The invention relates to the technical field of rubber, in particular to a fluorine rubber compound and a preparation method. Background technique [0002] In the modern industrial field, sealing technology plays a pivotal role, and it is the key to guarantee the performance of hydraulic and pneumatic systems. Once the sealing material fails, it will not only increase the subsequent maintenance cost, but also may lead to a fatal disaster. Material performance is the decisive factor for the performance of sealing products. In recent years, the use conditions of rubber seals have become increasingly severe, and the working conditions have become more and more severe. On the one hand, with the increasing requirements for sealing materials required for aerospace equipment, the Both high and low temperature have broken through the limit of the original working conditions, and the temperature range of the seal is wider; on the other hand, the media and addi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/16C08K13/06C08K9/06C08K3/04C08K3/34C08K3/22C08K3/26

CPCC08K2201/014C08L27/16C08L2201/08C08L2205/025C08K13/06C08K9/06C08K3/04C08K3/346C08K2003/222C08K2003/265

Inventor 邢华艳张建新汪仲权蔡醇洋

Owner ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com