Fast epoxy resin curing agent and preparation method thereof

A fast curing, epoxy resin technology, used in the field of curing agents, can solve the problems of affecting the scope of use and performance, poor media resistance, etc., and achieve the effects of low irritation, low odor and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

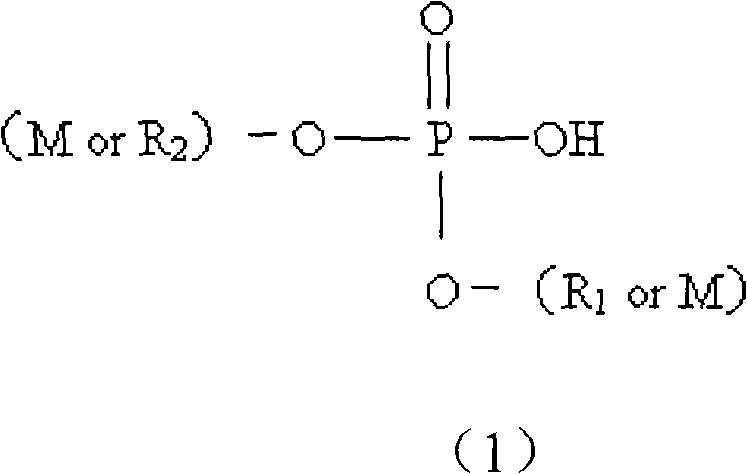

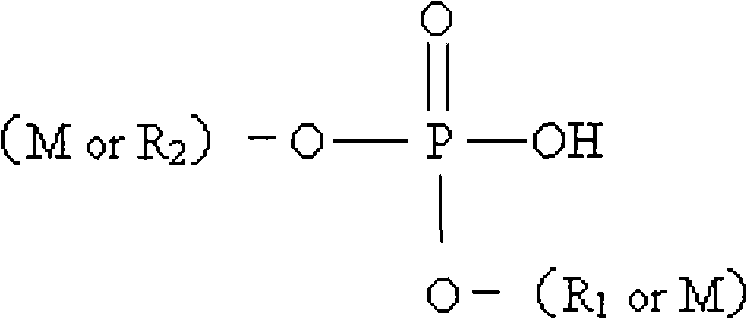

Method used

Image

Examples

Embodiment 1

[0034] Add 740 grams of molecular weight to 400, hydroxyl content is 5mmol / g, linear polyoxypropylene diol (polyether 204) with two functionalities in 2 reactors equipped with stirring, thermometer and dropping device, add dropwise while stirring 177.5 grams of polyphosphoric acid, and protect it with argon gas, control the reaction temperature at about 80 ° C, after the dropwise addition, adjust the temperature at 60 ° C and keep it warm for 2 hours with argon gas, then add 3 grams of water, and continue the heat preservation reaction for 2 hours . Cool down at 30°C, add 50 grams of Zn(CH 3 COO) 2 , and stirred for 2 hours to obtain a light yellow viscous transparent liquid.

[0035] After mixing with epoxy resin 828 at a mass ratio of 40:100, 50 g of the mixture was cured at 25° C. for 15 minutes. The cured product is immersed in water at 25°C, and after 30 days, the weight increases by 1%, and the surface is smooth, which is defined as excellent water resistance.

Embodiment 2

[0039] Add 177.5 grams of polyphosphoric acid to a 1-liter reactor equipped with a stirring, thermometer and dropping device, add 76 grams of propylene glycol dropwise while stirring, and protect it with argon, and control the reaction temperature below 80 ° C. , heat up to 80°C and keep warm for 3 hours to react with argon gas. Then add 5 grams of water, continue to keep warm for 2 hours, cool to 60°C, add 7 grams of calcium naphthenate, continue to stir for 2 hours, cool down to obtain light Brown transparent liquid.

[0040] After mixing with epoxy resin 828 at a mass ratio of 24:100, 50 g of the mixture was cured at 25° C. for 2 minutes. The cured product is immersed in 5% NaOH aqueous solution at 25°C, and after 7 days, the weight increases by 1.5%, and the surface is smooth, which is defined as excellent alkali water resistance.

[0041] Comparative example:

[0042]The same as the above preparation process, except that calcium naphthenate is not added after esterifica...

Embodiment 3

[0044] In order to verify the curing performance of the curing agent and epoxy resin, the curing agent obtained in Example 1 was mixed with epoxy resin 828 at a mass ratio of 40:100, used for bonding stainless steel / stainless steel, and placed at 25°C for 24 hours After that, the average tensile and shear strengths were 25MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com