Environmental-friendly drier and printing ink composition thereof

An environment-friendly drier, chloride technology, applied in the directions of driers, inks, household appliances, etc., can solve the problems of not explicitly mentioning multiple ligands, not mentioning the application effect of metal complexation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

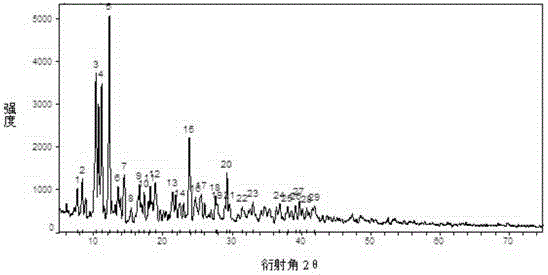

[0094] 2,4-bis-(2-pyridyl)-3-methyl-7-(pyridine-2-methyl)-3,7-diazabicyclo[3.3.1]nonan-9-one- Dimethyl 1,5-dicarboxylate (525g, 1mol) and 3,7-dimethyl-9-carbonyl-2,4-bis-(2-pyridyl)-3,7-diazabicyclo[ 3.3.1] Dimethyl nonan-9-one-1,5-dicarboxylate (870 g, 2 mol) was dissolved in acetone (9000 g) under an inert gas atmosphere at a temperature of 30°C. Slowly add saturated FeCl dropwise 2 4H 2 O (219g, 1.1mol) aqueous solution and saturated MnCl 2 4H 2 O (415.8g, 2.1mol) in water. After the addition, a yellow suspension was obtained. Stirring was continued for 1 hour, and a large amount of solid precipitated out. Filter, appropriate acetone washes filter cake, obtain light yellow solid powder 1540g after vacuum drying, yield 88%, have such as figure 1 The crystal structure diagram shown.

[0095] Slowly dissolve the solid powder in 1,2-propanediol to prepare an environment-friendly drier solution 1 with a concentration of 0.5%.

Embodiment 2

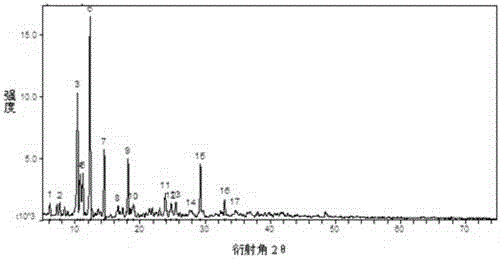

[0097] 2,4-bis-(2-pyridyl)-3-methyl-7-(pyridine-2-methyl)-3,7-diazabicyclo[3.3.1]nonan-9-one- Dimethyl 1,5-dicarboxylate (525g, 1mol) and 3,7-dimethyl-9-carbonyl-2,4-bis-(2-pyridyl)-3,7-diazabicyclo[ 3.3.1] Dimethyl nonan-9-one-1,5-dicarboxylate (1305 g, 3 mol) was dissolved in acetone (12000 g) under an inert gas atmosphere at a temperature of 32°C. Slowly add saturated FeCl dropwise 2 4H 2 O (219g, 1.1mol) aqueous solution and saturated MnCl 2 4H 2 O (634g, 3.2mol) aqueous solution. After the addition, a yellow suspension was obtained. Stirring was continued for 1.5 hours, and a large amount of solid precipitated out. Filter, appropriate acetone washes filter cake, obtain light yellow solid powder 2007g after vacuum drying, yield 86%, have such as figure 2 The crystal structure diagram shown.

[0098] Slowly dissolve the solid powder in 1,2-propanediol to prepare an environment-friendly drier solution 2 with a concentration of 5%.

Embodiment 3

[0100] Oxidative polymerization drying type lithographic offset printing ink composition (wt%):

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com