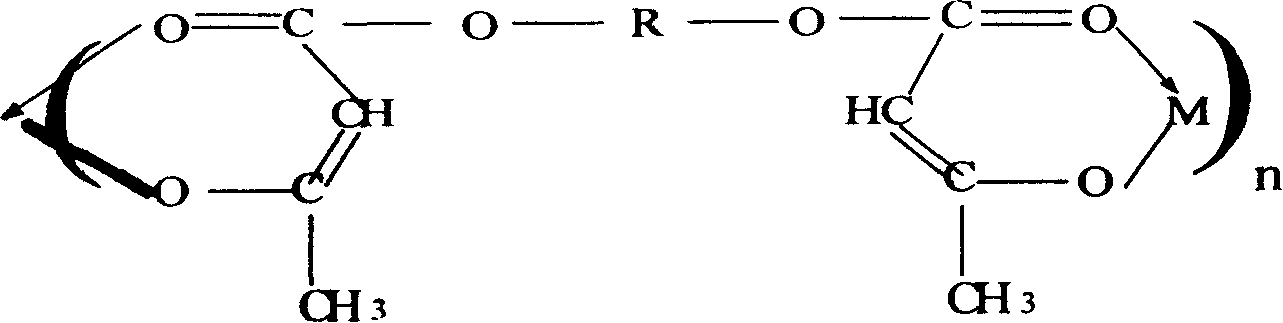

Oligomer diacetyl acetate alkylene diester metal chelate coating drier and preparation and application

A diacetoacetate and metal chelate technology, which is applied in the direction of drier, chemical instruments and methods, etc., can solve the problems that have not been seen, and the emulsification technology of drier is backward, so as to achieve low toxicity and increase storage stability , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A: Preparation of ethylene diacetoacetate

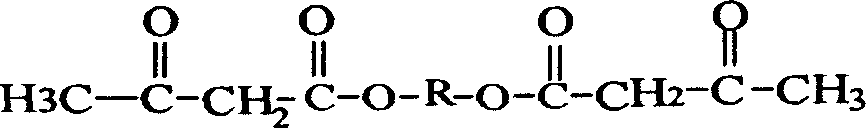

[0074] 1. Reaction equation:

[0075]

[0076] 2. Formulation:

[0077] Reactant Mole Mass (g)

[0078] Ethylene glycol 1.0 62

[0079] Diketene 2.0 168

[0080] Triethylamine (catalyst) 0.5

[0081] 3. Operation process:

[0082] Install the four-neck flask on an electric constant speed stirrer, install a reflux water separator, a condenser tube, and a drying tube at the left port, install a constant-pressure dropping funnel at the right port, and connect the nitrogen inlet pipe at the top port of the dropping funnel. The four ports were equipped with thermometers, and the reaction flask was heated with an electric heating mantle without an open flame.

[0083] Put ethylene glycol (anhydrous) and triethylamine (anhydrous) into the reaction bottle according to the recipe, heat up under stirring, and protect with nitrogen gas. Heat to 80°C, and slowly add diketene dropwise after the temperature stabilizes (the reactio...

Embodiment 2

[0114] A: Preparation of 1,4-butylene diester of diacetoacetate

[0115] 1. Reaction equation:

[0116]

[0117] 2. Formulation:

[0118] Reactant Mole Mass (g)

[0119] 1,4 Butanediol 1.0 90

[0120] Diketene 2.2 184.8

[0121] Triethylamine (catalyst) 0.5

[0122] 3. Operation process:

[0123] According to the reaction device of Example 1, 1,4-butanediol and triethylamine were put into the reaction bottle, and the temperature was raised under stirring, and nitrogen protection was carried out. Heating to 80°C, and slowly adding diketene dropwise after stabilization (the reaction exothermic is violent, so the rate of addition is controlled so that the temperature is controlled at about 80°C). After the diketene is added dropwise, react at 90°C-100°C for 2 hours.

[0124] After the reaction is completed, distill under reduced pressure to recover unreacted diketene (diketene is easy to polymerize at high temperature) at 10 mm Hg, with a boiling range of 50° C. to 70° ...

Embodiment 3

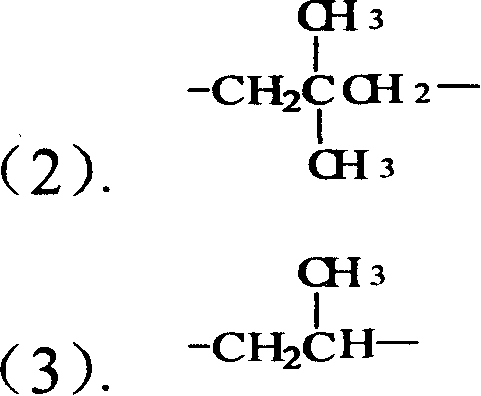

[0155] A: Preparation of 1,3 neopentylene diester of diacetoacetate:

[0156] 1. Reaction equation:

[0157]

[0158] 2. Formulation:

[0159] Reactant Mole Mass (g)

[0160] Neopentyl glycol 1.0 104

[0161] Diketene 2.0 168

[0162] Triethylamine (catalyst) 0.5

[0163] 3. Operation process:

[0164] According to the reaction device of Example 1, put neopentyl glycol and an appropriate amount of toluene into the reaction bottle, heat up to 114°C under stirring, reflux for dehydration, cool to 80°C after removing water, add triethylamine, and start after the reaction temperature is stable. Slowly add diketene dropwise, and the temperature is controlled at about 80°C. After the diketene is added dropwise, react at about 80°C for 1 hour, depending on the completeness of the reaction of diketene, and the end point of the reaction is controlled by gas chromatography.

[0165] After the reaction was complete, the reactant was cooled. Toluene and diketene were distilled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com