Composite dryer for paint and production method thereof

The technology of a composite drier and a production method is applied in the field of coating composite drier and its production, and can solve the problems of high price, large amount of addition, complicated procedures and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

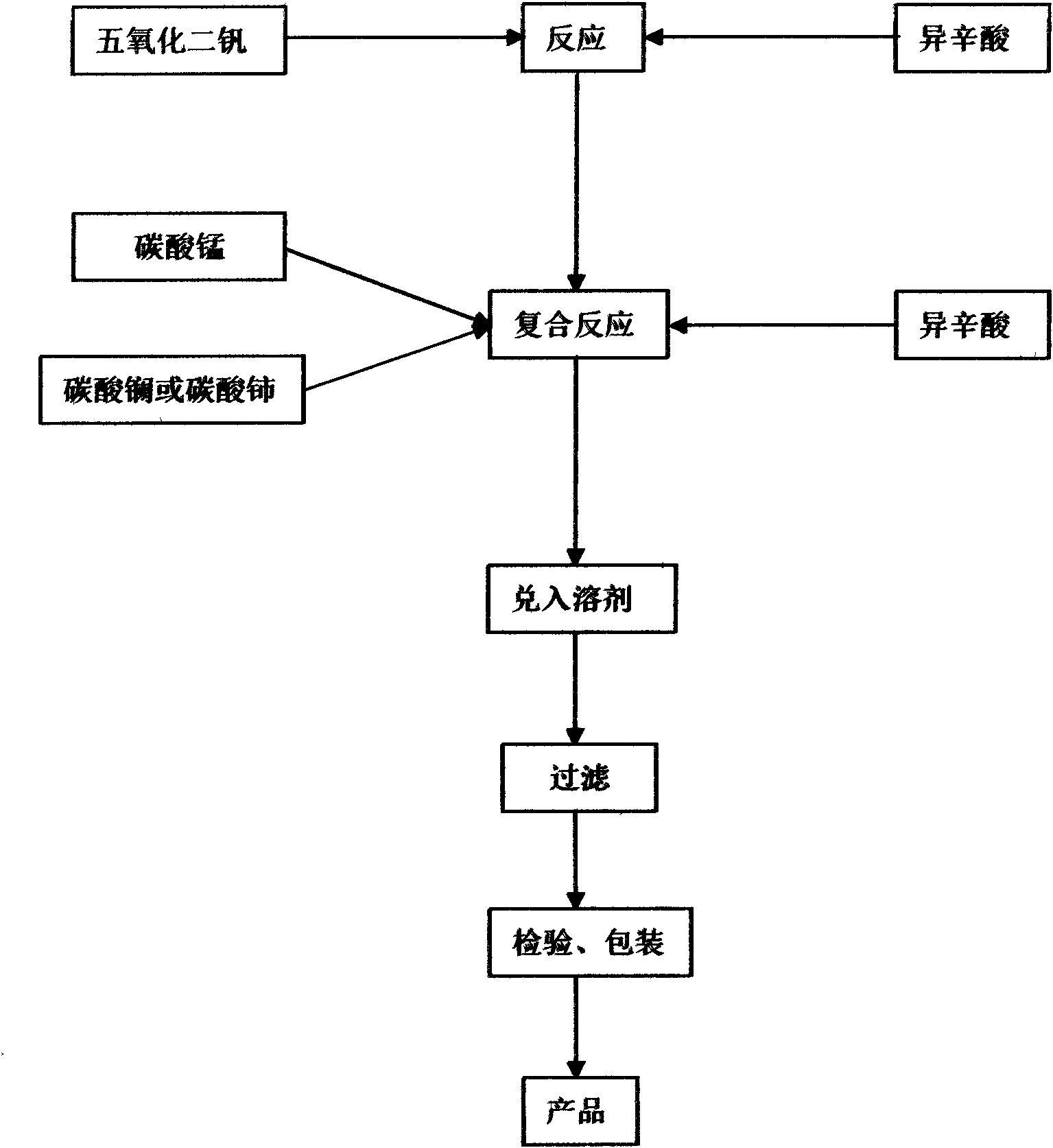

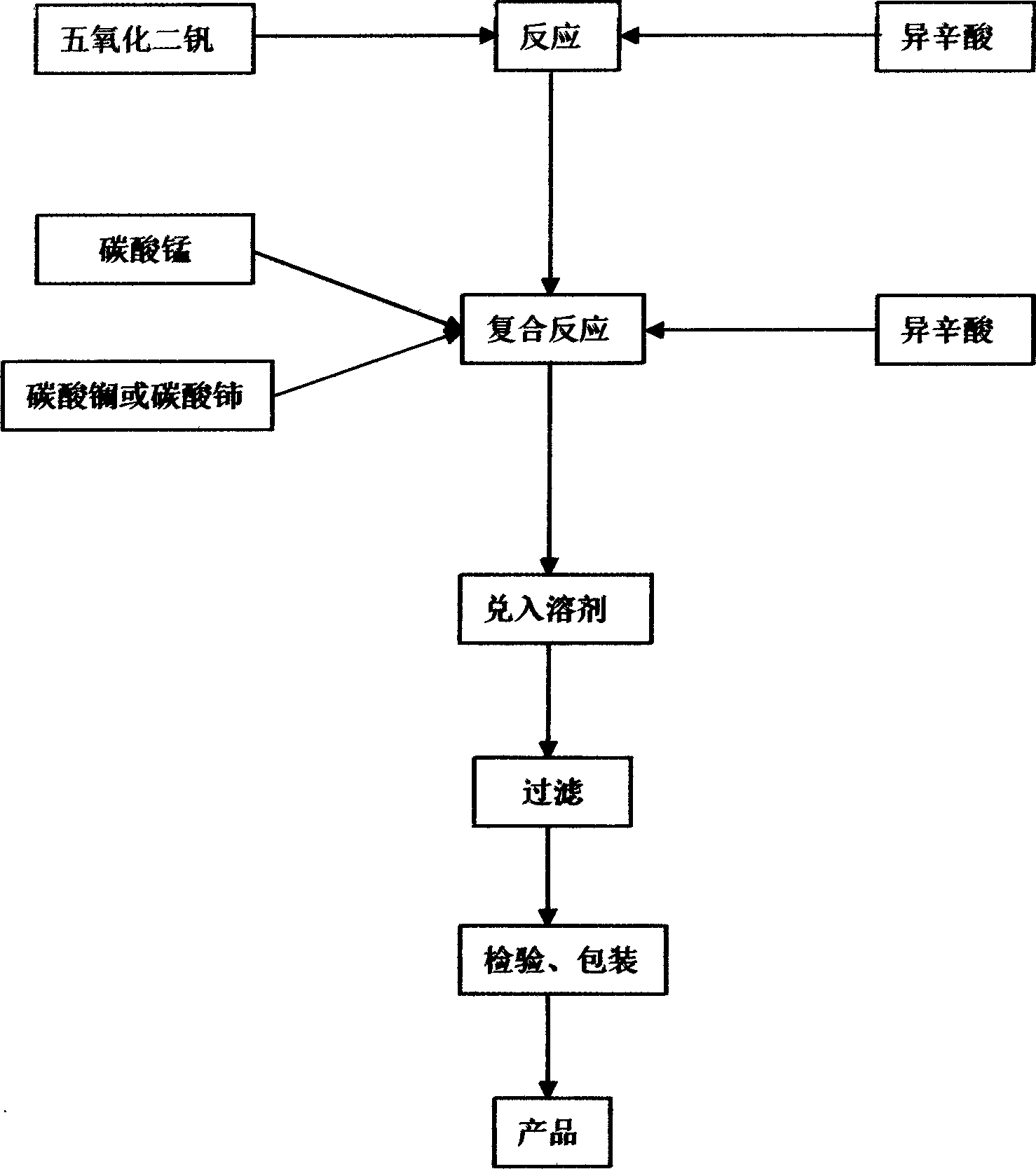

[0013] The production method of the paint composite drier involved in the present invention is to carry out compound reaction with light rare earth carbonate——lanthanum carbonate or cerium carbonate (both can be added simultaneously), manganese carbonate, vanadium pentoxide and isooctanoic acid, and its process The process is shown in Figure 1.

[0014] The specific implementation steps are:

[0015] First, vanadium pentoxide and isooctanoic acid are added to the reaction kettle for reaction, the ratio of the two is about 1:4 to 1:5 (the ratio here is the ratio of vanadium ions to isooctanoate ions, that is, 1 vanadium ion Corresponding to 4 to 5 isooctanoic acid ions). The reaction temperature is between 100°C and 250°C (the optimum temperature is 220°C and 230°C), and it is stirred, and the reaction time is about 2 hours.

[0016] Then continue to add manganese carbonate in the reactor, add light rare earth carbonate (lanthanum carbonate or cerium carbonate), and add isooc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com