Preparation method of composite rare earth drier for oil paint

A compound rare earth and drier technology, applied in drier, chemical instruments and methods, etc., can solve problems such as environmental pollution, poor impact resistance, etc., achieve thorough reaction, promote paint film drying, and increase drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

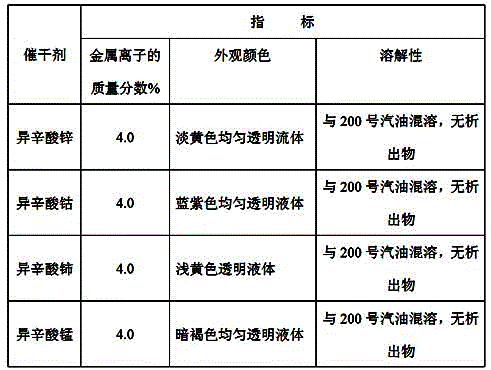

[0044] C in the compound rare earth drier for paint of this embodiment O 2+ 、Ce 3+ , Mn 2+ , Zn 2+ The mass ratio of C is 7:50:5:3; C O 2+ 、Ce 3+ , Mn 2+ , Zn 2+ The sum of the mass is 4% of the total mass of the composite rare earth drier for paint.

[0045] The preparation method of cerium isooctanoate in this embodiment is as follows: mix cerium carbonate, organic mixed acid and No. 200 solvent gasoline, set the temperature at 145 ° C, stir for 4 hours, and reflux the solvent during the reaction process, wherein, cerium carbonate, organic mixed acid The mass ratio of solvent gasoline to No. 200 is 1:2.2:13.1; the mass ratio of isooctanoic acid and naphthenic acid in organic mixed acids is 1:1.

[0046] The preparation method of manganese isooctanoate is as follows: mix manganese carbonate, organic mixed acid, and No. 200 solvent gasoline, and stir for 90 minutes under the condition of 120°C to 150°C. During the reaction, the solvent is refluxed. Among them, mangane...

Embodiment 2

[0050] C in the compound rare earth drier for paint of this embodiment O 2+ 、Ce 3+ , Mn 2+ , Zn 2+ The mass ratio is 6:30:4:1.

[0051] In the preparation process of cerium isooctanoate in this example, the mass ratio of isooctanoic acid to naphthenic acid is 3:1.

[0052] In the preparation process of manganese isooctanoate in this example, the mass ratio of isooctanoic acid to naphthenic acid is 2.5:1.

Embodiment 3

[0054] C in the compound rare earth drier for paint of this embodiment O 2+ 、Ce 3+ , Mn 2+ , Zn 2+ The mass ratio is 8:40:6:2.

[0055] In the preparation process of cerium isooctanoate in this example, the mass ratio of isooctanoic acid to naphthenic acid is 2:1.

[0056] In the preparation process of manganese isooctanoate in this example, the mass ratio of isooctanoic acid to naphthenic acid is 3:1.

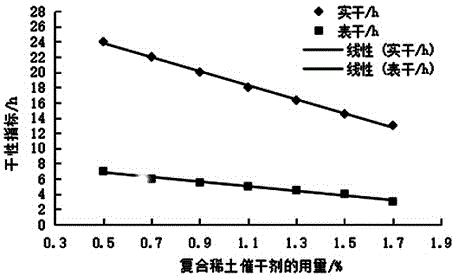

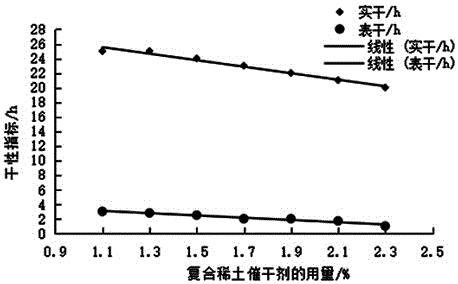

[0057] 6. Paint drying test:

[0058] The composite rare earth driers prepared in Example 1, Example 2 and Example 3 were respectively added to alkyd varnish and novolak varnish for application test. The dryness index of the experiment took the paint produced by a certain company as a sample, and measured it based on the technical indicators in GB / T25251-2010 "Alkyd Resin Coatings" and GB / T25253-2010 "Phenolic Resin Coatings". These two national standards It is required that the surface dry time of alkyd varnish is ≤5 hours, and the hard drying time is ≤15 hours; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com