Biogas residue organic fertilizer and preparation method thereof

A biogas residue organic fertilizer and biogas residue technology, which is applied in the direction of organic fertilizer, bio-organic part treatment, fertilization device, etc., can solve the problems of difficult biogas residue treatment, secondary pollution, waste of resources, etc., and achieve the improvement of fertilizer utilization rate and improvement Quality and the effect of improving corporate profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

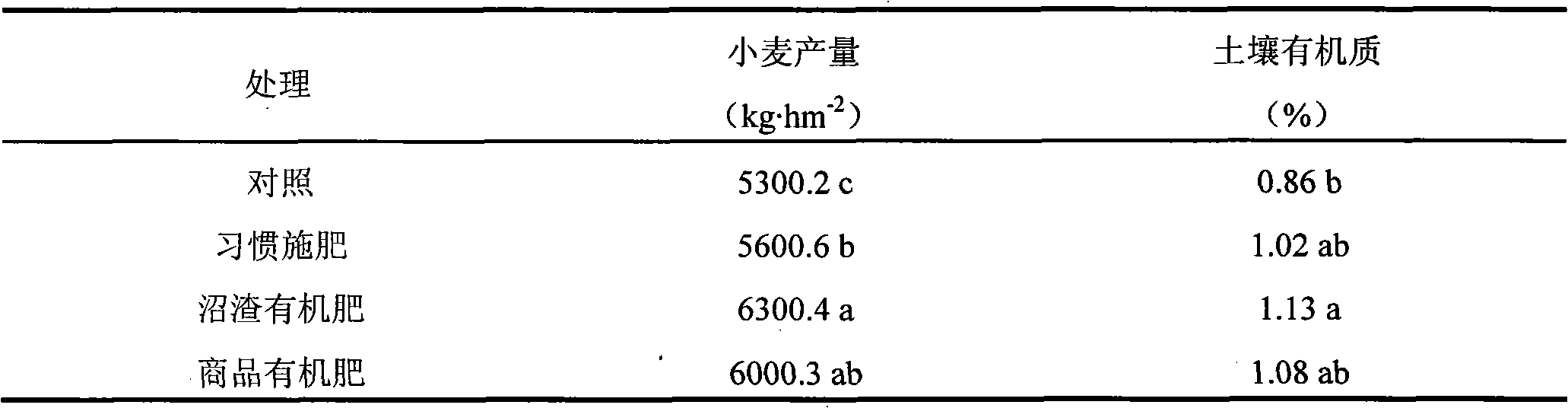

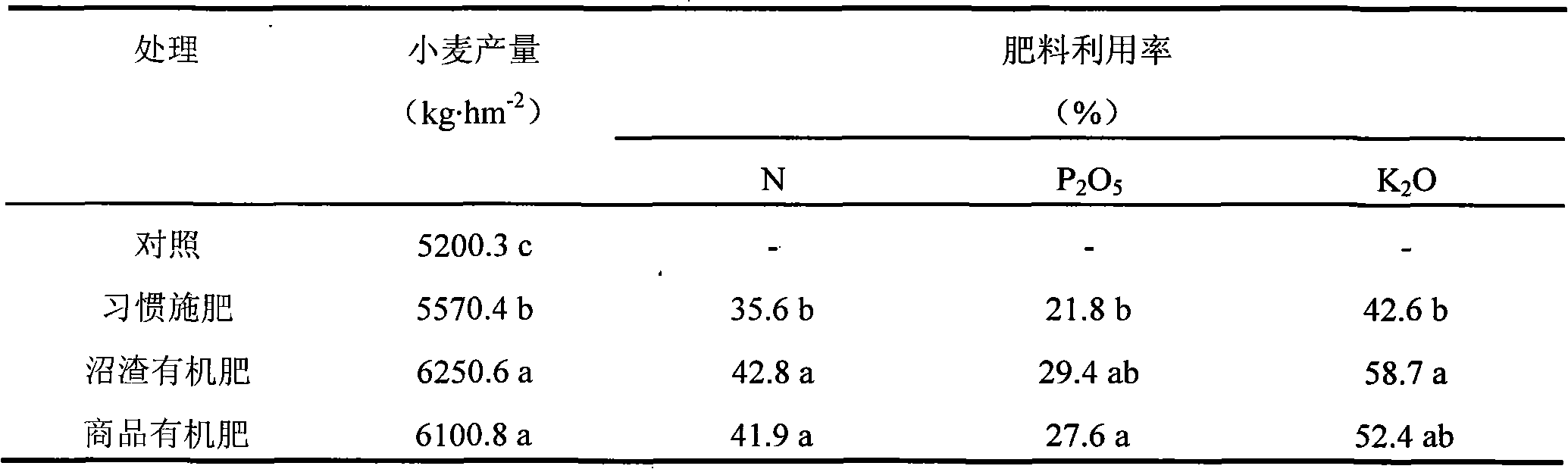

[0050] Embodiment 1: special biogas residue organic fertilizer for wheat

[0051] Raw material component parts by weight are as follows:

[0052] Biogas residue (water content less than 30%) 92 parts; humic acid (organic matter > 50%) 4.5 parts; ammonium sulfate 1 part; potassium sulfate 1 part; monoammonium phosphate 1 part; manganese sulfate 0.2 part; zinc sulfate 0.2 part; boric acid 0.1 part.

[0053] The preparation steps are as follows:

[0054] 1. Pretreatment of biogas residue

[0055] The moisture content of the biogas residue in the biogas anaerobic fermentation tank is 86wt%, and it is pumped into the solid-liquid separator by a slurry pump, and the moisture content of the biogas residue after solid-liquid separation is 60%. The biogas residue after solid-liquid separation is sent to the solidification pond for air-drying and solidification. The depth of the solidification pond is 0.5 meters, and the curing time is 6 months, so that the moisture content of the bi...

Embodiment 2

[0062] Embodiment 2, special biogas residue organic fertilizer for wheat, raw material component weight parts are as follows:

[0063] Biogas residue (water content less than 30%) 90.8 parts; humic acid (organic matter > 50%) 5 parts; ammonium sulfate 1.5 parts; potassium sulfate 1 part; monoammonium phosphate 1 part; manganese sulfate 0.3 parts; zinc sulfate 0.3 parts; boric acid 0.1 part.

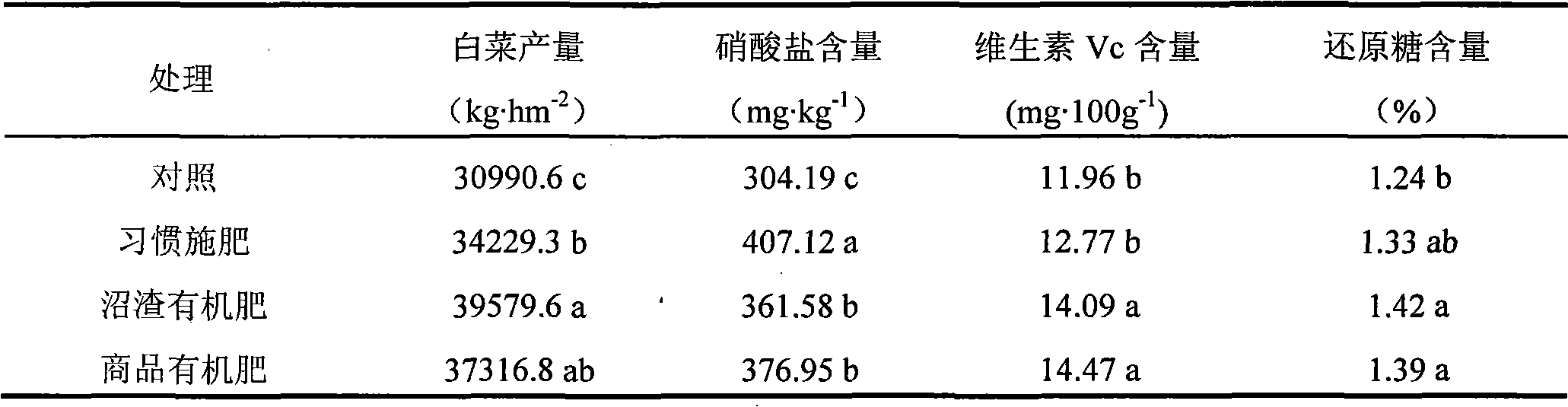

Embodiment 3

[0064] Embodiment 3, biogas residue organic fertilizer special for vegetables, raw material component weight parts are as follows:

[0065] Biogas residue (water content less than 30%) 85.25 parts; humic acid (organic matter > 50%) 10 parts; ammonium sulfate 2 parts; potassium sulfate 1 part; monoammonium phosphate 1 part; manganese sulfate 0.3 parts; zinc sulfate 0.25 parts; boric acid 0.2 parts.

[0066] Preparation method is as embodiment 1, and difference is:

[0067] 1. Pretreatment of biogas residue

[0068] The moisture content of the biogas residue in the biogas anaerobic fermentation tank is 90wt%, and it is pumped into the solid-liquid separator by a slurry pump, and the moisture content of the biogas residue after solid-liquid separation is 61wt%. The biogas residue after solid-liquid separation is sent to the solidification tank for air-drying and solidification. The depth of the solidification tank is 0.8 meters. When a special turning machine is used to regular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com