Method for circulating and reutilizing sludge during process of sewage

A sludge recycling and sewage treatment technology, applied in the field of waste pollutant treatment, can solve the problems of secondary pollution, high infrastructure investment and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

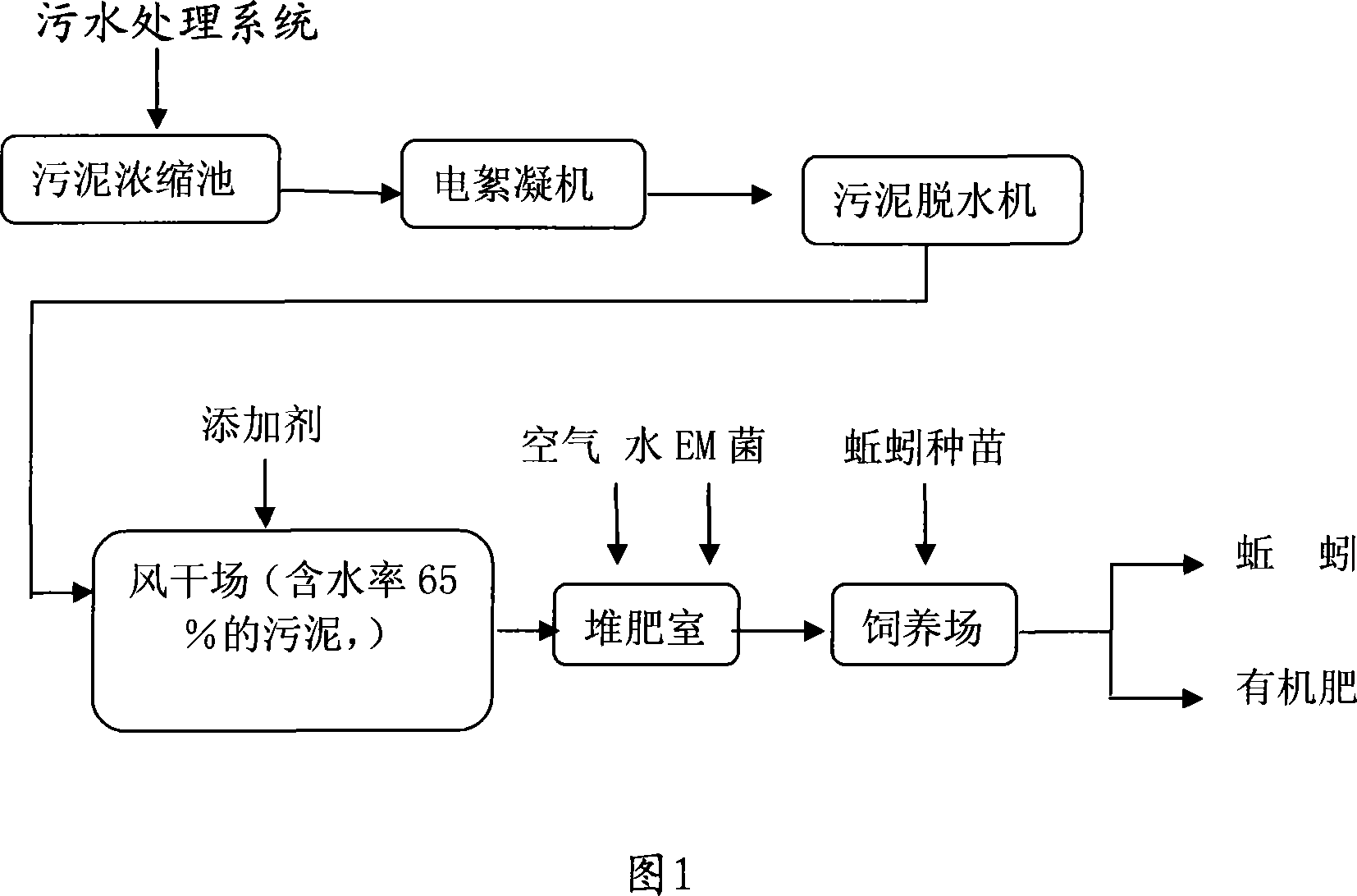

[0049] The invention provides a sludge recycling method in the process of sewage treatment. The method uses the combination of three technologies: EC (electric flocculation machine), EM (beneficial microorganism engineering bacteria), and EW (earthworm).

[0050] The specific steps of the method of the present invention, please refer to Fig. 1, after the sludge of the sewage treatment plant is treated by EC (electric flocculation machine), remove the heavy metal, pesticide and antibiotic residue in the sludge, then enter the sludge dewatering machine for dehydration, and dehydrate The final sludge is sent to the air-drying field for air-drying, and additives (pig manure, bean dregs, etc.) are added to adjust the ratio of N, P, and K in the sludge, and the air-drying sludge is sent to the composting room for composting, and air is sent to the composting room , Sprinkle water and stir regularly, add EM (engineering bacteria), after a period of fermentation, send the composted com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com