Domestic garbage transformation technique, system and apparatus without conventional fuel for combustion supporting

A technology for domestic waste and conventional fuel, applied in the field of incineration system equipment and waste gasification, can solve problems such as inability to effectively eliminate carcinogenic and highly toxic dioxins, complex flue gas purification systems, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

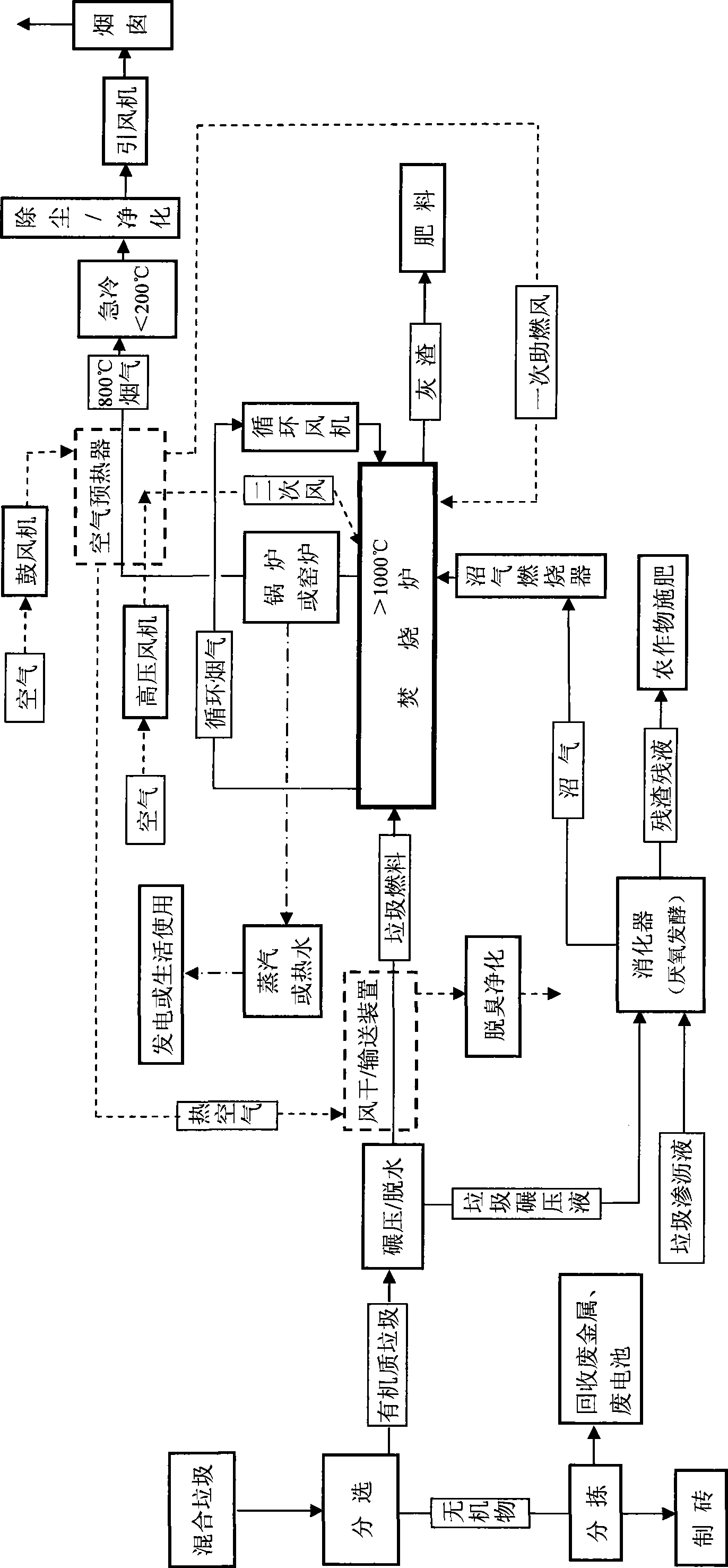

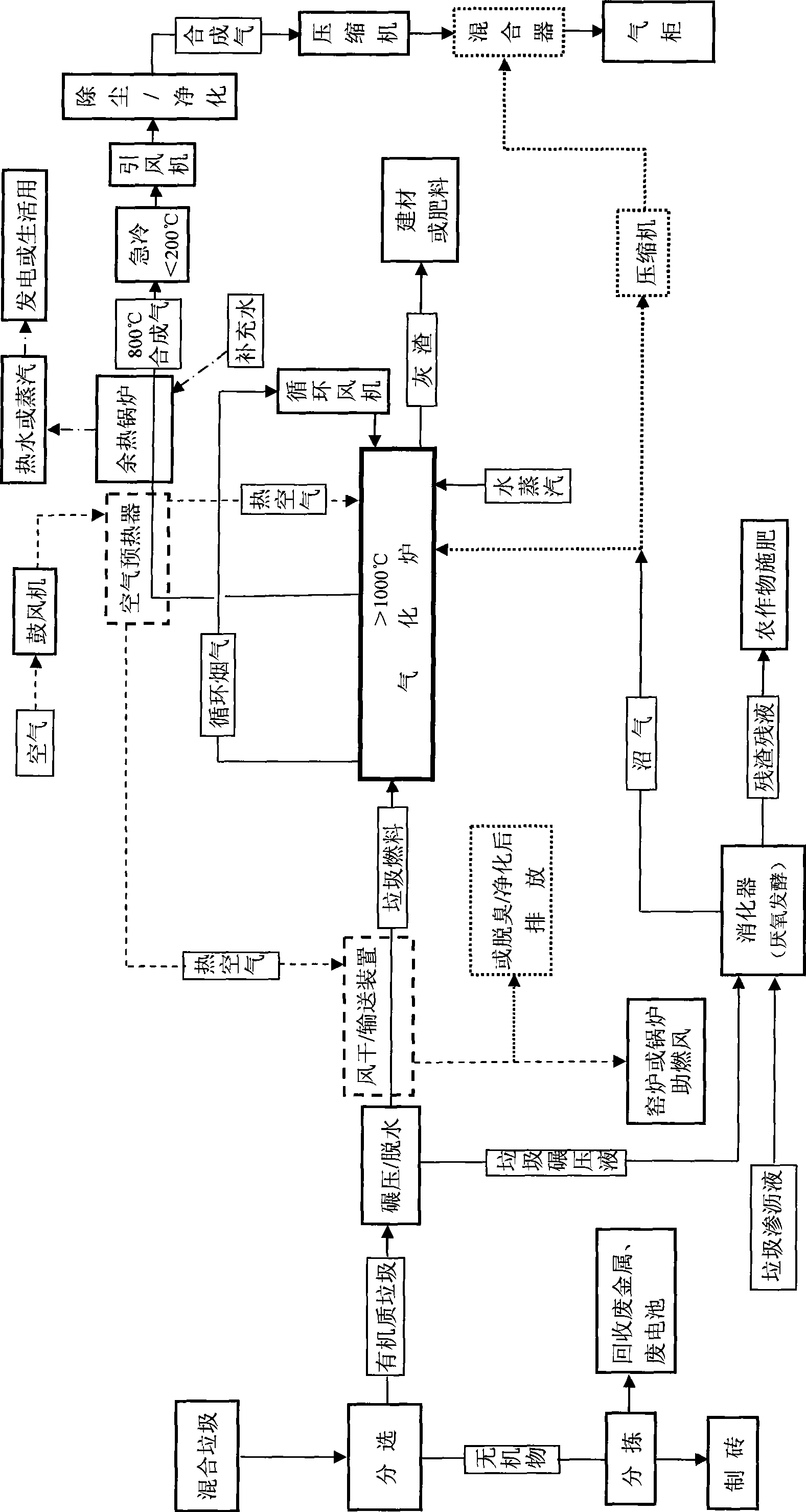

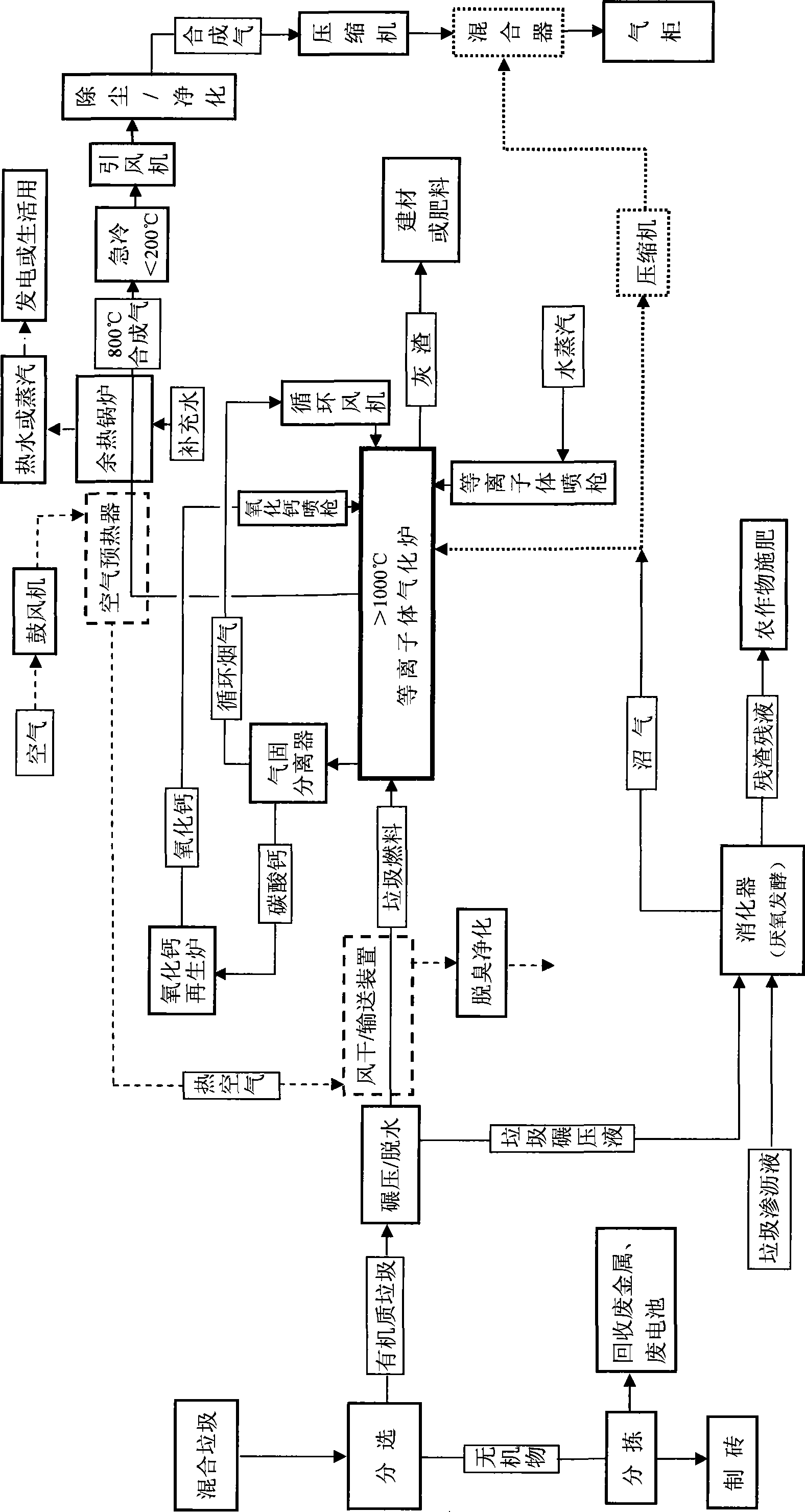

[0028] figure 1 The conversion process of domestic waste incineration method shown mainly consists of waste sorting, rolling / dehydration, air drying / transportation, gasification / incineration, heat energy utilization, flue gas quenching, dust removal / purification, waste rolling liquid digestion and treatment, Inorganic brick making and other processes, among which the incinerator is a flue gas circulation incinerator. The mixed garbage mixed with inorganic substances such as masonry, mud and sand is mechanically sorted or manually sorted to select the organic garbage, and then the organic garbage is rolled and dehydrated, and the garbage rolling liquid and garbage generated during the rolling and dehydrating process are separated. The garbage leachate from the storage pit is sent to the digester to produce biogas by anaerobic fermentation. The biogas is used as auxiliary fuel for the incinerator, and the digested residue is used as fertilizer; the organic waste after rolling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com