Preparation method of composite rare earth oxide reinforced molybdenum alloy piercing mandrel

A technology of compounding rare earths and oxides, which is applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of reduced service life of the plug, sticking steel, thick pier, etc., to increase the recrystallization temperature, reduce the turning cost, Effect of improving high temperature hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

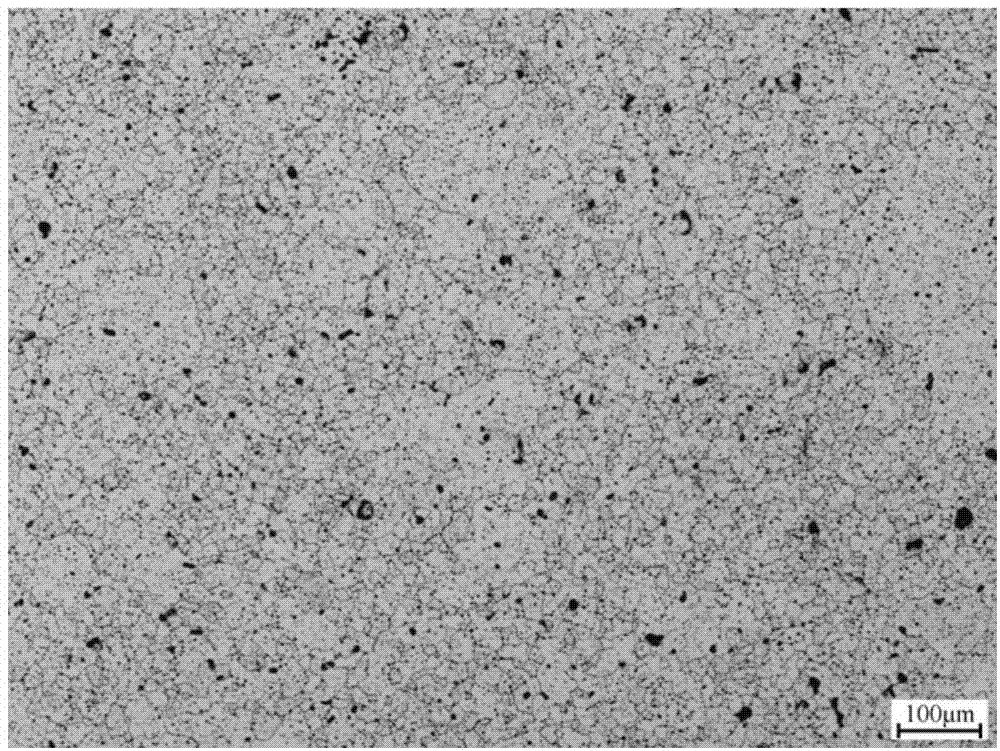

[0031] The method for preparing the molybdenum alloy plug whose finished product size is Φ54mm * 145mm (wherein the total length of the plug is 145mm, and the diameter of the sizing area is 54mm) comprises the following steps:

[0032] Step 1. Put carbon powder, titanium hydride powder, zirconium hydride powder and rare earth oxide powder in a three-dimensional mixer (purchased from Nanjing Feiyu Pharmaceutical Equipment Co., Ltd., model SYH-1200), and mix under vacuum for 60 minutes , to obtain doping powder, then place the doping powder and molybdenum powder in a horizontal mixer and mix for 120min to obtain the mixed powder raw material; the rare earth oxide powder is cerium oxide powder and yttrium oxide powder, and the mixing The quality of carbon powder in the powder raw material is 0.3% of the mass of molybdenum powder, the quality of titanium hydride powder is 1.29% of the mass of molybdenum powder, the quality of zirconium hydride powder is 0.3% of the mass of molybden...

Embodiment 2

[0049] The method for preparing the molybdenum alloy plug whose finished product size is Φ64mm * 145mm (wherein the total length of the plug is 145mm, and the diameter of the sizing area is 64mm) comprises the following steps:

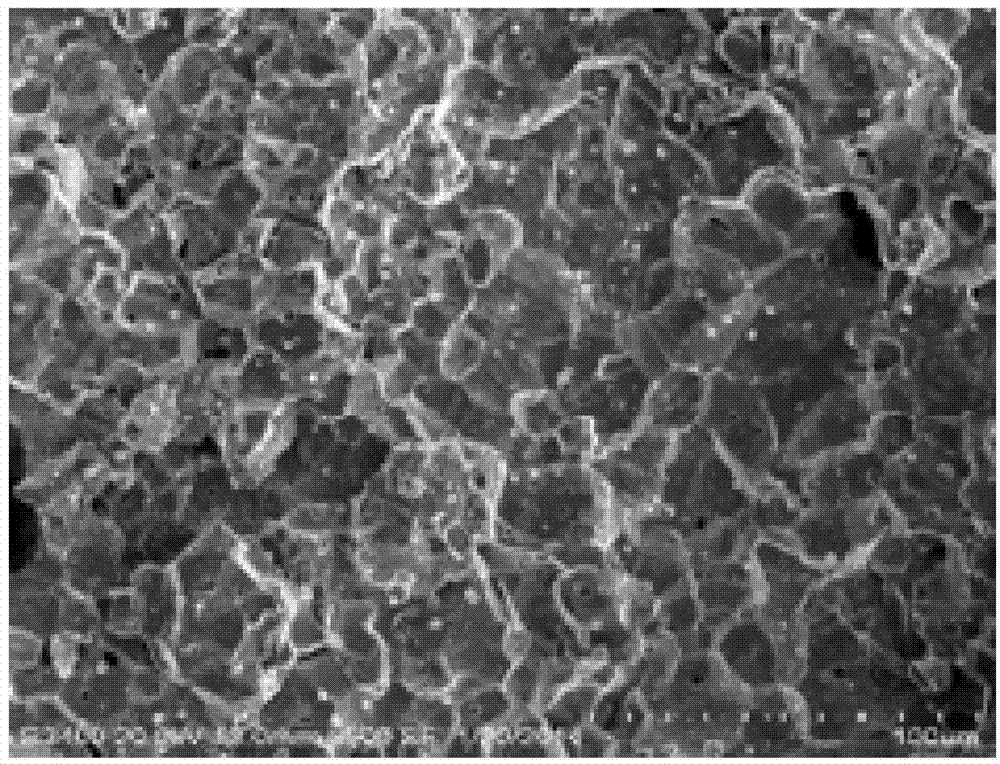

[0050] Step 1. Put carbon powder, titanium hydride powder, zirconium hydride powder and rare earth oxide powder in a three-dimensional mixer (purchased from Nanjing Feiyu Pharmaceutical Equipment Co., Ltd., model SYH-1200), and mix under vacuum for 60 minutes , to obtain doping powder, then place the doping powder and molybdenum powder in a horizontal mixer and mix for 120min to obtain the mixed powder raw material; the rare earth oxide powder is cerium oxide powder and yttrium oxide powder, and the mixing The mass of carbon powder in the powder raw material is 0.3% of the mass of molybdenum powder, the mass of titanium hydride powder is 1.3% of the mass of molybdenum powder, the mass of zirconium hydride powder is 0.3% of the mass of molybdenum powder,...

Embodiment 3

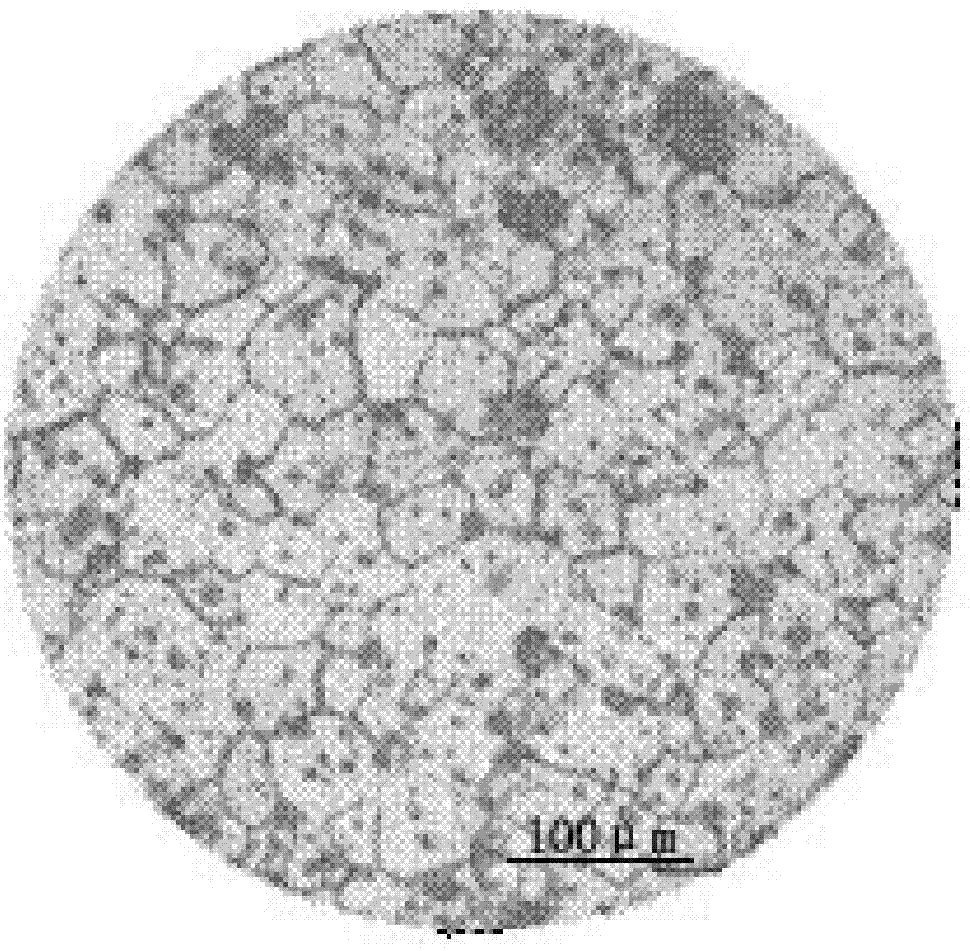

[0057] The method for preparing the molybdenum alloy plug whose finished product size is Φ74mm * 165mm (wherein the total length of the plug is 165mm, and the diameter of the sizing area is 74mm) comprises the following steps:

[0058] Step 1. Put carbon powder, titanium hydride powder, zirconium hydride powder and rare earth oxide powder in a three-dimensional mixer (purchased from Nanjing Feiyu Pharmaceutical Equipment Co., Ltd., model SYH-1500), and mix under vacuum for 90 minutes , to obtain doping powder, then place the doping powder and molybdenum powder in a horizontal mixer and mix for 90min to obtain the mixed powder raw material; the rare earth oxide powder is cerium oxide powder and yttrium oxide powder, and the mixing The mass of carbon powder in the powder raw material is 0.25% of the mass of molybdenum powder, the mass of titanium hydride powder is 1.25% of the mass of molybdenum powder, the mass of zirconium hydride powder is 0.28% of the mass of molybdenum powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com