A flexural toughness testing machine for fiber-reinforced reinforced concrete

A technology of reinforced concrete and bending toughness, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as high noise, and achieve the effect of solving large noise, simple and convenient operation, and high leveling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

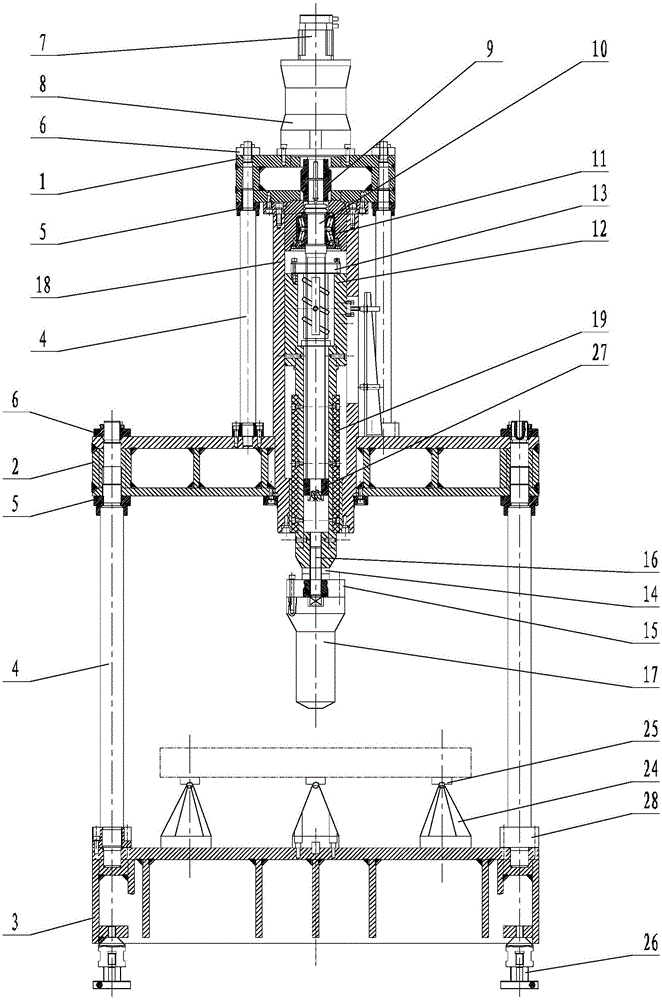

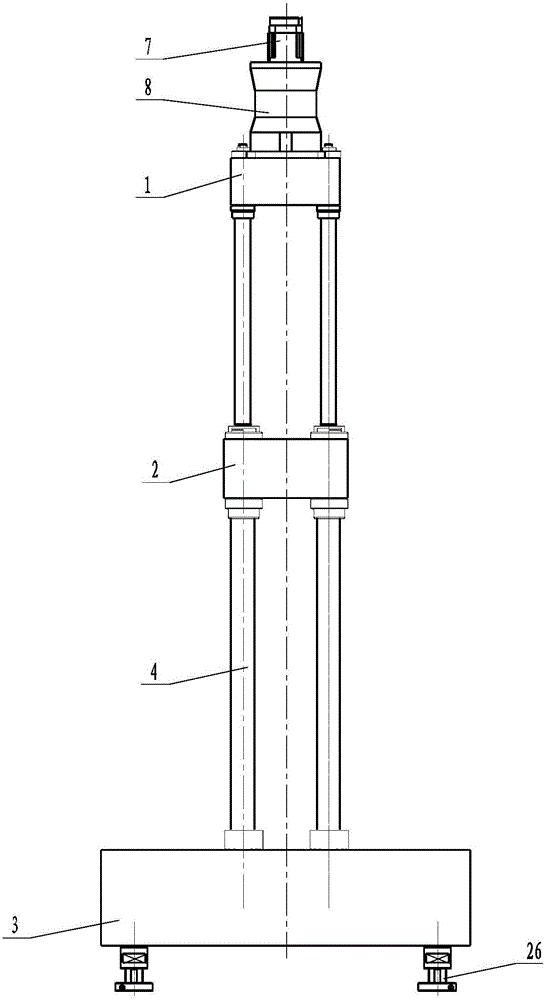

[0043] The present invention will be further described below in conjunction with accompanying drawing.

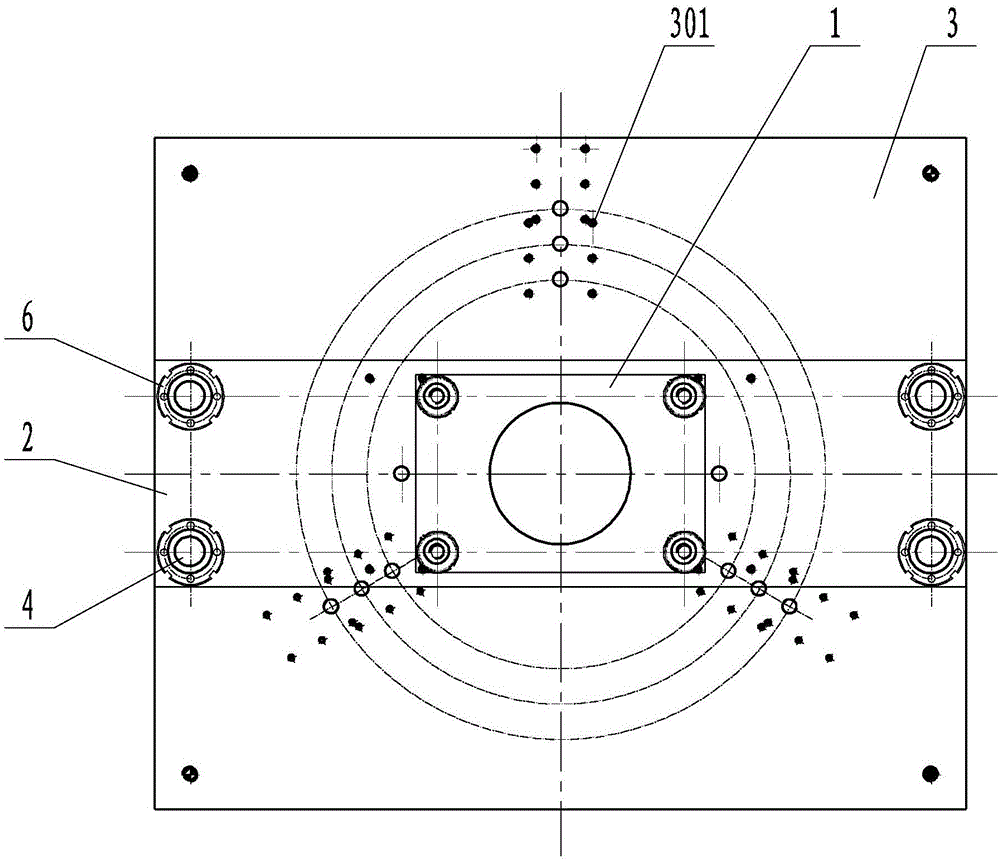

[0044] Such as Figure 1~3 As shown, the vertical three-layer support frame is assembled from the upper beam 1, the middle beam 2 and the horizontal force base 3 arranged layer by layer from top to bottom through two layers of bearing columns 4. The upper beam 1, the middle beam 2 and the The stressed base 3 is a hollow steel frame structure, which is welded as a whole by upper and lower two horizontal steel plates and a vertical support plate welded at intervals between the two. The number of bearing columns 4 on each floor is four, and they are symmetrically arranged on the four corners of the beams 1 and 2 along the center of the support frame.

[0045] Such as Figure 4 As shown, the supporting column 4 is a six-stage stepped shaft with threaded sections, from top to bottom, the third threaded section, the third optical axis section, the second threaded section, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com