Chitosan modified geopolymer cementing material

A technology of chitosan modification and geopolymer, applied in cement production, etc., can solve the problems of high brittleness, complicated process, poor flexural performance and toughness, and achieve the effect of improving toughness, simple working process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

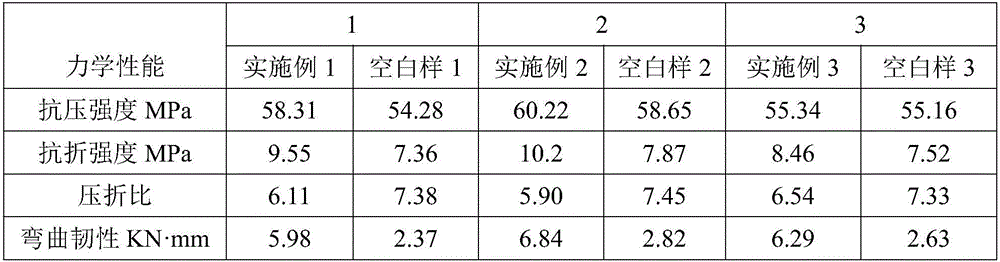

Embodiment 1

[0028] Add 1 g of carboxymethyl chitosan to 100 g of a mixed solution of potassium hydroxide and sodium silicate with a modulus of 1, and stir thoroughly at 30° C. for 1 h to obtain a uniform mixed solution. Take 1000g of blast furnace slag, gradually add the previously uniform mixed solution into it, and fully stir it at 20°C for 20 minutes, then inject it into the mold and vibrate to remove the air in the reactant. After reacting at room temperature (about 20°C) for 24 hours, demould, then seal the sample with a sealed bag and put it in an incubator at room temperature (about 20°C) for 28 days to obtain a geopolymer sample. At this time, the compressive strength was measured to be 58.31MPa, the flexural strength was 9.55MPa, the folding ratio was 6.11, and the flexural toughness coefficient was 5.98KN·mm.

Embodiment 2

[0030] Add 1 g of hydroxypropyl chitosan to 100 g of a mixed solution of potassium hydroxide and sodium silicate with a modulus of 1, and stir thoroughly at 50° C. for 1 h to obtain a uniform mixed solution. Take 1000g of blast furnace slag, gradually add the previously uniform mixed solution into it, and fully stir it at 20°C for 20 minutes, then inject it into the mold and vibrate to remove the air in the reactant. After reacting at room temperature (about 20°C) for 24 hours, demould, then seal the sample with a sealed bag and put it in an incubator at room temperature (about 20°C) for 28 days to obtain a geopolymer sample. At this time, the compressive strength was measured to be 60.22MPa, the flexural strength was 10.2MPa, the folding ratio was 5.90, and the bending toughness coefficient was 6.84KN·mm.

Embodiment 3

[0032] Add 1.5g N-trimethyl chitosan into 100g mixed solution of potassium hydroxide and sodium silicate with a modulus of 1, and fully stir at 50° C. for 1 hour to obtain a uniform mixed solution. Take 1000g of blast furnace slag, gradually add the previously uniform mixed solution into it, and fully stir it at 20°C for 20 minutes, then inject it into the mold and vibrate to remove the air in the reactant. After reacting at room temperature (about 20°C) for 24 hours, demould, then seal the sample with a sealed bag and put it in an incubator at room temperature (about 20°C) for 28 days to obtain a geopolymer sample. At this time, the compressive strength was measured to be 55.34MPa, the flexural strength was 8.46MPa, the folding ratio was 6.54, and the bending toughness coefficient was 6.29KN·mm.

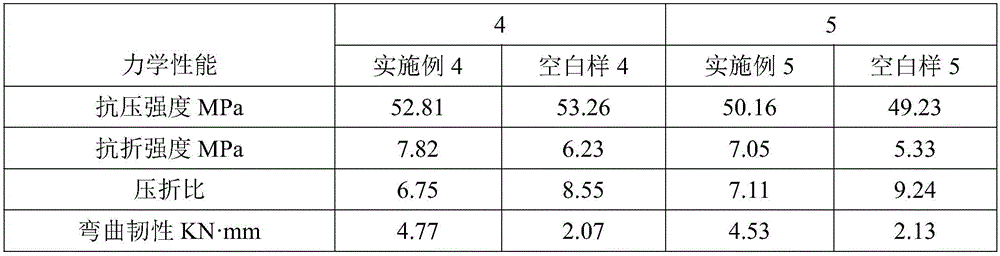

[0033] The above Examples 1-3 and respective blank sample 28d mechanical properties are drawn in the following table 1 (the blank sample is identical with the embodiment except that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com