Testing method and device for flexural toughness of fiber reinforced concrete components

A fiber reinforced concrete, bending toughness technology, applied in the direction of using a stable bending force to test the strength of materials, etc., can solve the problem that the measuring device and method have not been developed, and achieve the effect of removing the influence of inertial force, high precision and high loading speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

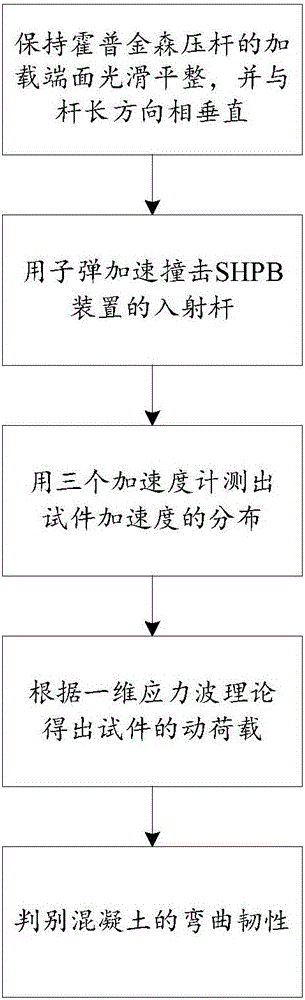

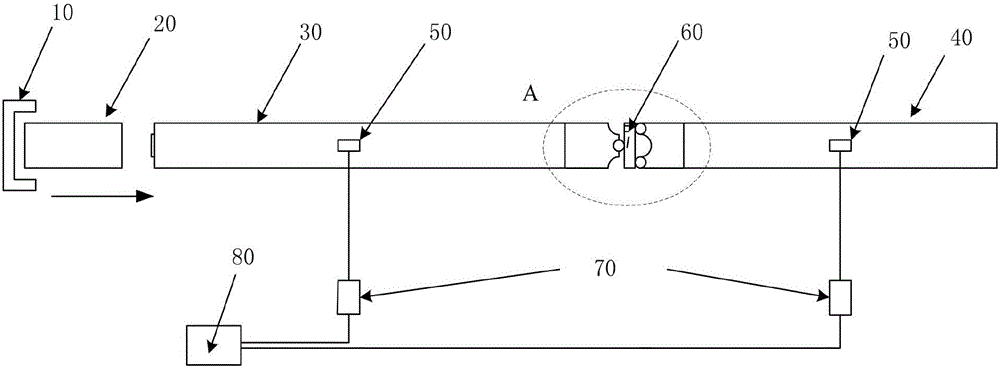

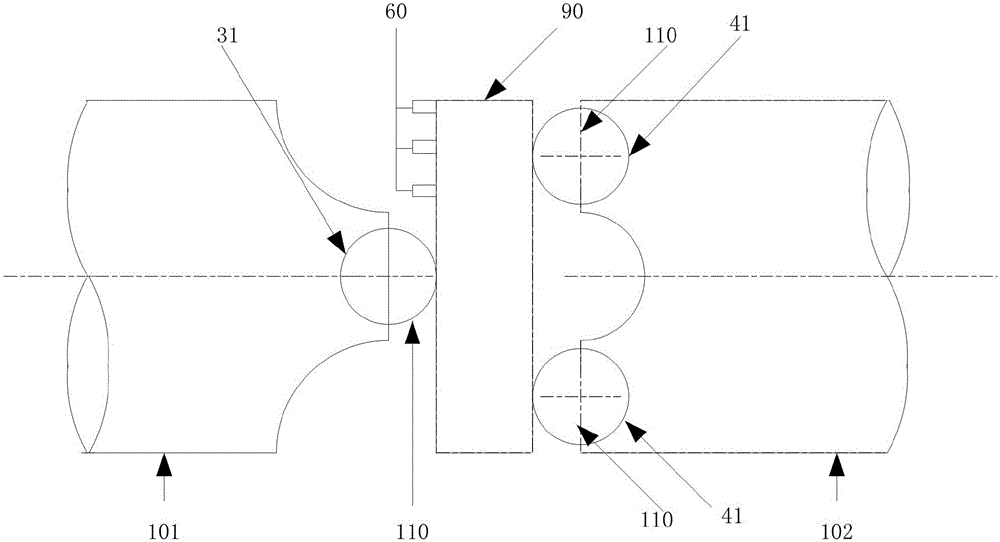

[0045]The flexural toughness test method of the fiber concrete component of the present invention is based on the flexural toughness test device of the concrete component composed of a separated Hopkinson compression bar device to perform the flexural toughness test on the concrete specimen (90), and the flexural toughness test device includes an air gun ( 10), bullet (20), incident rod (30), transmission rod (40), strain gauge (50), accelerometer (60), bridge box (70), data acquisition system (80) connected with computer;

[0046] During the test, keep the loading end surface of the Hopkinson compression bar smooth and flat, and perpendicular to the length direction of the bar;

[0047] The bullet (20) in the air gun (10) is accelerated to hit the end of the incident rod (30) without notches and cracks, thereby generating an incident compression pulse in the incident rod (30) and propagating toward the concrete specimen (90) ;

[0048] When the incident pulse hits the comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com