Grouting material for energy-consuming node of prefabricated part

A technology of prefabricated components and grouting materials, applied in the field of building materials, can solve the problems of labor-consuming and time-consuming binding of steel bars, large shrinkage, poor toughness and ductility, and low cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

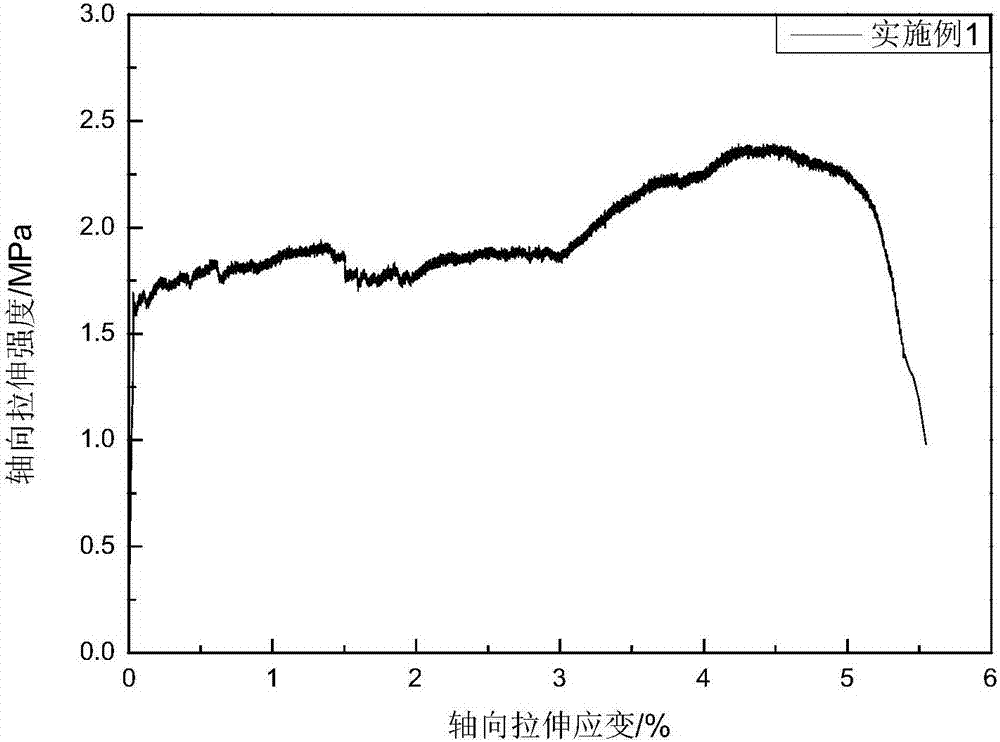

Embodiment 1

[0036] Embodiment 1 material composition ratio such as table 1:

[0037] Table 1 Mixing ratio of new grouting materials for energy-dissipating nodes of prefabricated components (mass fraction)

[0038]

[0039] The raw material used in embodiment 1 is:

[0040] The gelling material is mainly composed of CaO and SiO 2 、Al 2 o 3 powder; fine aggregate, fine aggregate A is ordinary river sand with a particle size of 0.15 mm to 1.18 mm and a fineness modulus of 1.65; fine aggregate B is mainly composed of CaCO 3 Granules; plastic regulators are polycarboxylate superplasticizers and cellulose ethers; water is tap water; fibers are synthetic fibers and are polyvinyl alcohol fibers.

[0041] Example 1 Prepare the new type of grouting material for energy-dissipating nodes of the above-mentioned prefabricated components, the steps are:

[0042] (1) Accurately weigh all powder materials such as gelling materials and fine aggregates, and mix at low speed for 2 minutes;

[0043] ...

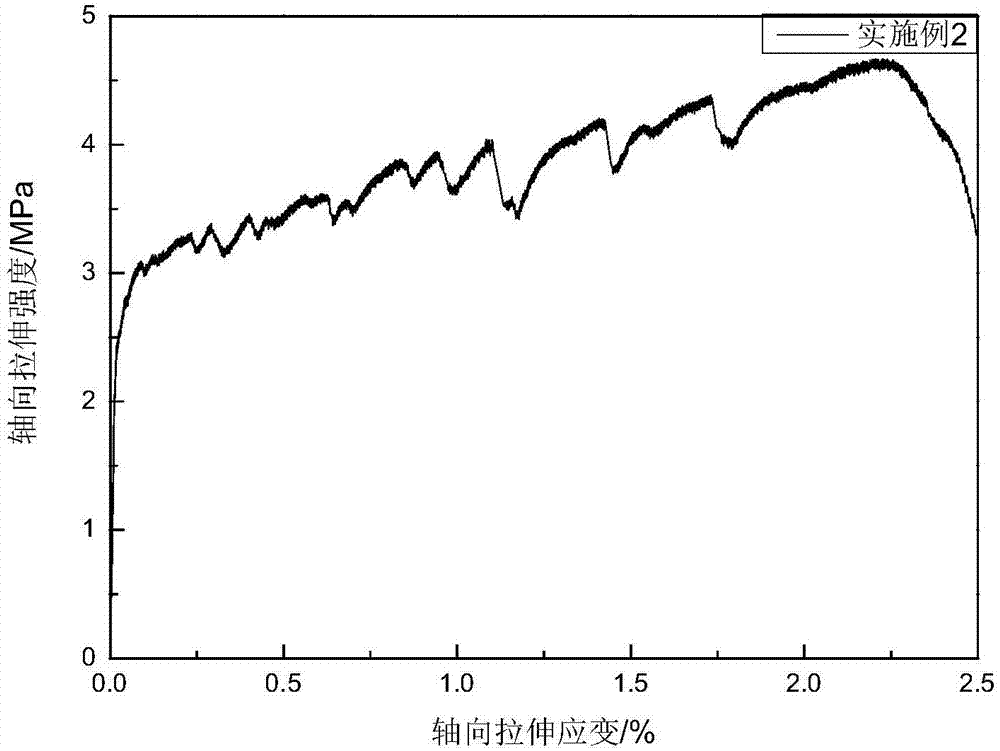

Embodiment 2

[0048] Embodiment 2 material composition ratio such as table 2:

[0049] Table 2 Mixing ratio of new grouting materials for energy-dissipating nodes of prefabricated components (mass fraction)

[0050]

[0051] The raw materials used in embodiment 2 are:

[0052] The gelling material is mainly composed of CaO and SiO 2 、Al 2 o 3 powder; fine aggregate, fine aggregate A is ordinary river sand with a particle size of 0.15 mm to 1.18 mm and a fineness modulus of 1.65; fine aggregate B is mainly composed of CaCO 3 Granules; plastic regulators are polycarboxylate superplasticizers and cellulose ethers; water is tap water; synthetic fibers are polyvinyl alcohol fibers.

[0053] Example 2 Prepare the new type of grouting material for energy-dissipating nodes of the above-mentioned prefabricated components, the steps are:

[0054] (1) Accurately weigh all powder materials such as gelling materials and fine aggregates, and mix at low speed for 2 minutes;

[0055] (2) Add water...

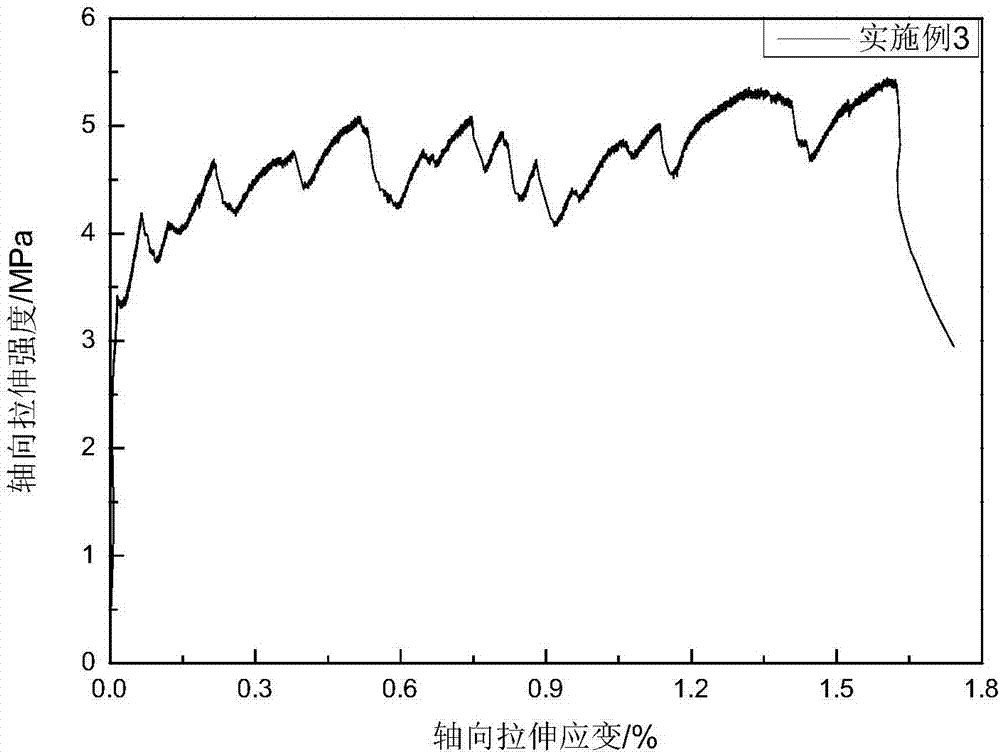

Embodiment 3

[0060] Embodiment 3 material composition ratio such as table 3:

[0061] Table 3 Mixing ratio of new grouting materials for energy-dissipating nodes of prefabricated components (mass fraction)

[0062]

[0063] The raw materials used in embodiment 3 are:

[0064] The gelling material is mainly composed of CaO and SiO 2 、Al 2 o 3 powder; fine aggregate, fine aggregate A is ordinary river sand with a particle size of 0.15 mm to 1.18 mm and a fineness modulus of 1.65; fine aggregate B is mainly composed of CaCO 3 Granules; plastic regulators are polycarboxylate superplasticizers and cellulose ethers; water is tap water; synthetic fibers are polyvinyl alcohol fibers.

[0065] Example 3 Prepare the new type of grouting material for the energy-dissipating nodes of the above-mentioned prefabricated components, and the steps are as follows:

[0066] (1) Accurately weigh all powder materials such as gelling materials and fine aggregates, and mix at low speed for 2 minutes;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com