High-toughness and high-strength gypsum product and preparation method thereof

A high-strength gypsum and high-toughness technology, applied in the field of high-toughness and high-strength gypsum products and their preparation, can solve the problems of low strength and poor toughness, and achieve the advantages of increasing flexural strength and tensile strength, and enhancing flexural strength and hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. A high-toughness and high-strength gypsum product, comprising the following components in parts by weight: 75 parts of α-gypsum powder, 18 parts of filler (white marble powder), 0.35 part of dispersant (HQ-F20), 0.12 part of defoamer, 3.5 parts of dispersible latex powder, 8 parts of gypsum whiskers, 1.3 parts of glass staple fiber (or 0.13 part of chemical fiber staple fiber).

[0021] 2. The preparation method of the high-toughness and high-strength gypsum product comprises the following steps:

[0022] Step 1. Weigh the raw materials according to the formula, dry mix and mix;

[0023] Step 2, then add water (the total volume of the added water is 20% of the total weight of the mixed material) and stir, and pour the high-toughness and high-strength gypsum slurry into a gypsum mold through hydrothermal reaction to obtain the high-toughness and high-strength gypsum product. Surface hardness up to 6H.

Embodiment 2

[0025] 1. A high-toughness and high-strength gypsum product, comprising the following components in parts by weight: 70 parts of beta gypsum powder, 20 parts of filler (quartz sand), 0.2 part of dispersant (HQ-F20), 0.1 part of defoamer, 2 parts of dispersible latex powder, 5 parts of gypsum whiskers, 1 part of glass staple fiber (or 0.1 part of chemical fiber staple fiber).

[0026] 2. The preparation method of the high-toughness and high-strength gypsum product comprises the following steps:

[0027] Step 1, weighing the raw material components according to the formula and dry mixing;

[0028] Step 2, then add water (the total volume of the added water is 55% of the total weight of the mixed material) and stir, and pour the high-toughness and high-strength gypsum slurry into a gypsum mold through hydrothermal reaction to obtain the high-toughness and high-strength gypsum product. The surface hardness reaches 4H.

Embodiment 3

[0030] 1. A high-toughness and high-strength gypsum product, comprising the following components in parts by weight: 80 parts of α gypsum powder, 15 parts of filler (sandstone), 0.5 part of dispersant (HQ-20F), 0.2 part of defoamer, dispersible 5 parts of permanent latex powder, 10 parts of gypsum whiskers, 2 parts of glass staple fiber (or 0.2 part of chemical fiber staple fiber).

[0031] 2. The preparation method of the high-toughness and high-strength gypsum product comprises the following steps:

[0032] Step 1, weighing the raw material components according to the formula and dry mixing;

[0033] Step 2, then add water (the total volume of the added water is 20% of the total weight of the mixed material) and stir, and pour the high-toughness and high-strength gypsum slurry into a gypsum mold through hydrothermal reaction to obtain the high-toughness and high-strength gypsum product. The surface hardness reaches 5H.

PUM

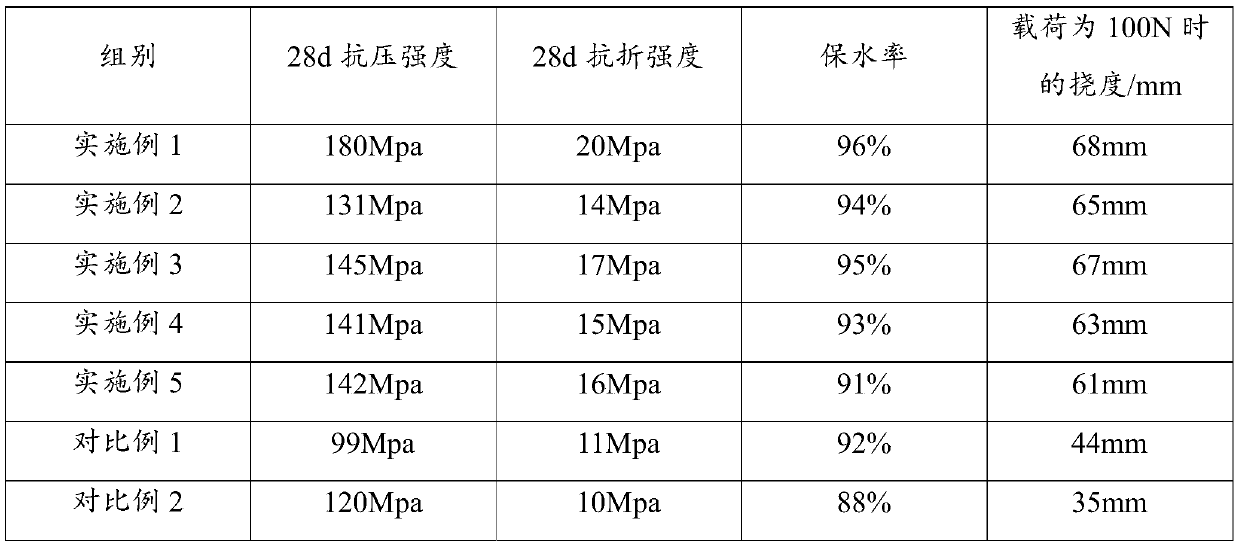

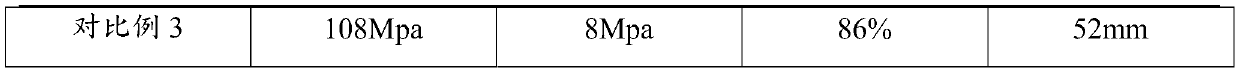

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Deflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com