Sampling method for disc-process shotcrete flexural toughness testing

A shotcrete and flexural toughness technology, used in the preparation of test samples, manufacturing tools, unloading devices, etc., can solve the problems of inability to make concrete specimens, blocking screw rotation, and difficulty in fixing side grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings. Limitations of Invention.

[0017] Specific steps are as follows:

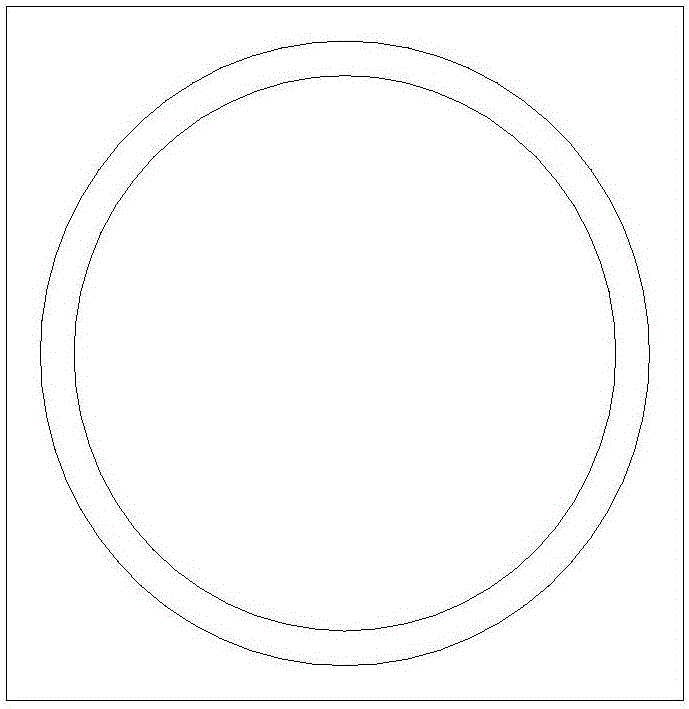

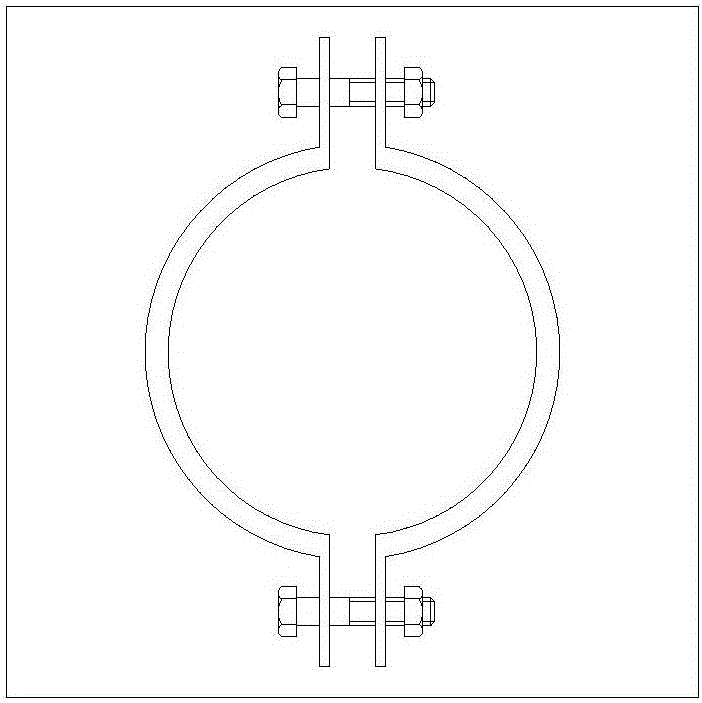

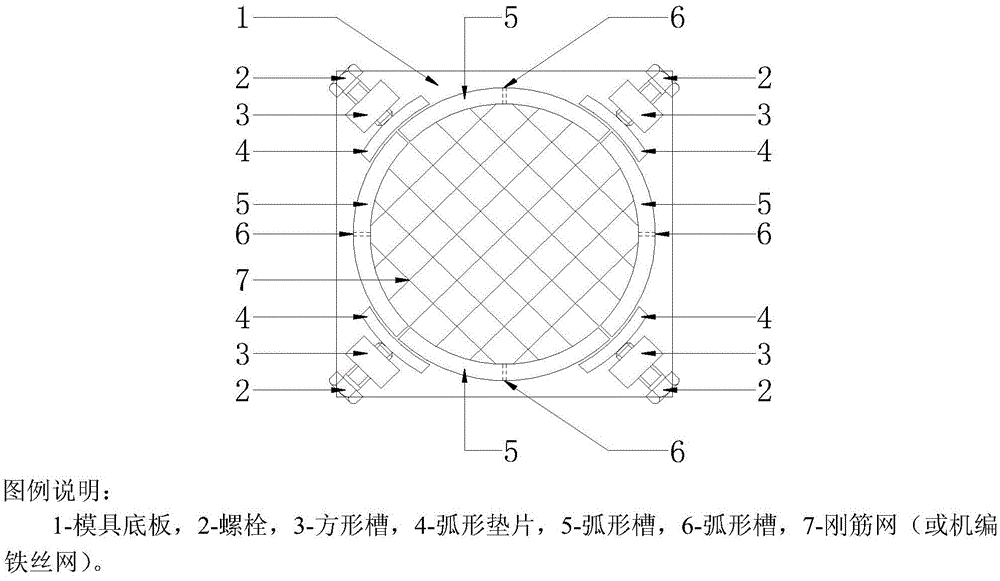

[0018] 1. Mold assembly: put the mold bottom plate (such as Figure 4 shown) on a flat surface. Then four sections of arc-shaped slots (such as Figure 5 shown) on the bottom plate to initially assemble into a complete circular side groove (such as Figure 6 shown), and then rotate the four bolts to the outside of the mold until the arc-shaped gasket can be accommodated between each arc-shaped groove joint and the bolt. At this time, put in the arc-shaped gasket and tighten the four bolts respectively to complete The fixation of the mold, the effect is as follows Figure 7 shown. According to the needs, the fine iron wire can be introduced into the drilled hole in the assembled mold, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com