Vertical integral forming mould of novel prefabricated concrete segment and forming method thereof

A technology of prefabricated concrete and integral molding, applied in molds, reinforced molding, manufacturing tools, etc., can solve the problems of being unsuitable for the promotion and application of small and medium-sized enterprises, high cost of high-precision molds, and affecting the quality of the protective layer, so as to achieve good reusability and environmental protection. The effect of spelling is good, and the effect of avoiding shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiment: In order to have a clearer understanding of the process characteristics, purpose and effect of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

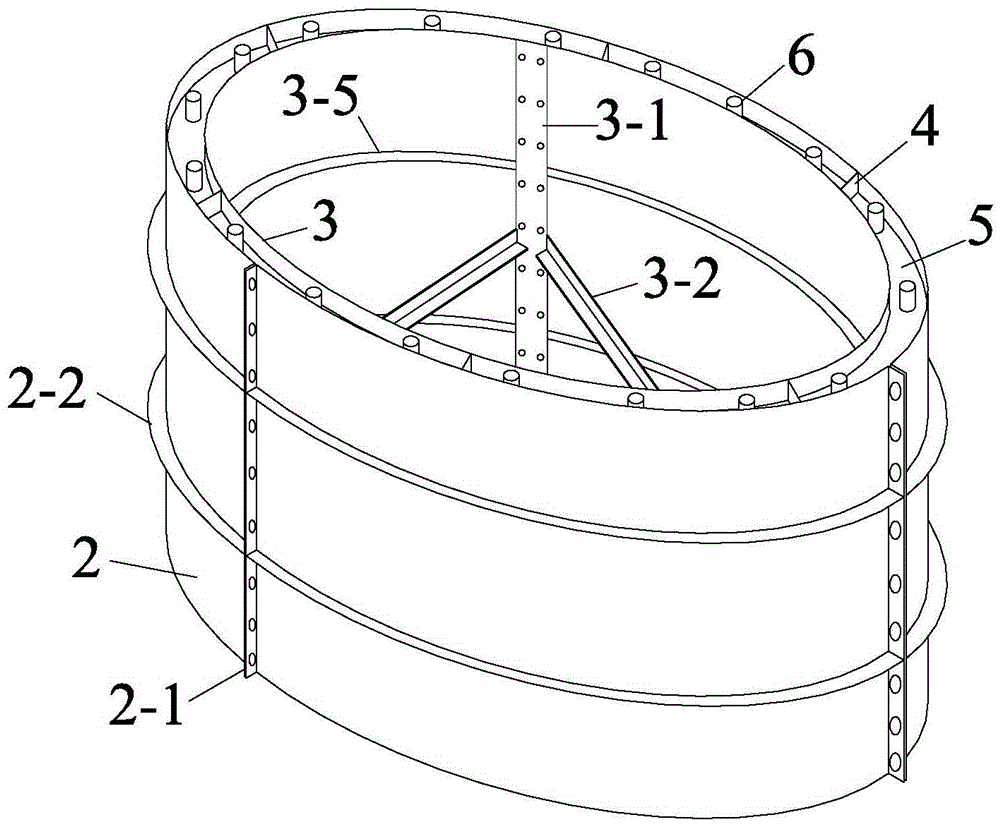

[0053] figure 1 It is a three-dimensional structural schematic diagram of the vertical integral molding mold for precast concrete segment in the embodiment of the present invention, mainly including bottom mold 1, outer formwork 2, inner formwork 3, block plate 4, cover plate 5, positioning pin 6 and other components.

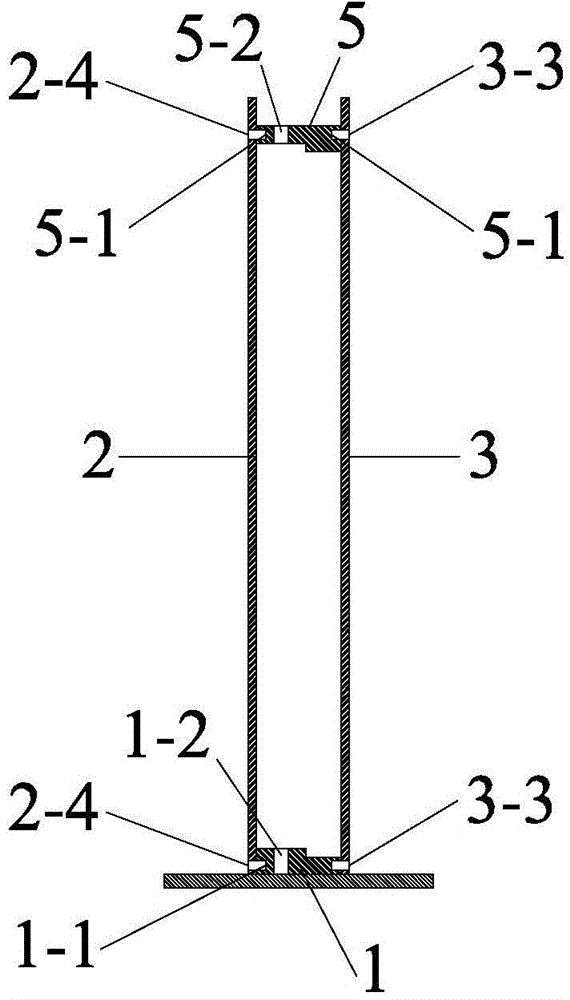

[0054] figure 2 It is a schematic diagram of the longitudinal section of the forming mold. The precast concrete segment is formed in the gap between the outer steel mold 2, the inner steel mold 3, the bottom mold 1 and the cover plate 5, and its longitudinal section shape is shown in the figure.

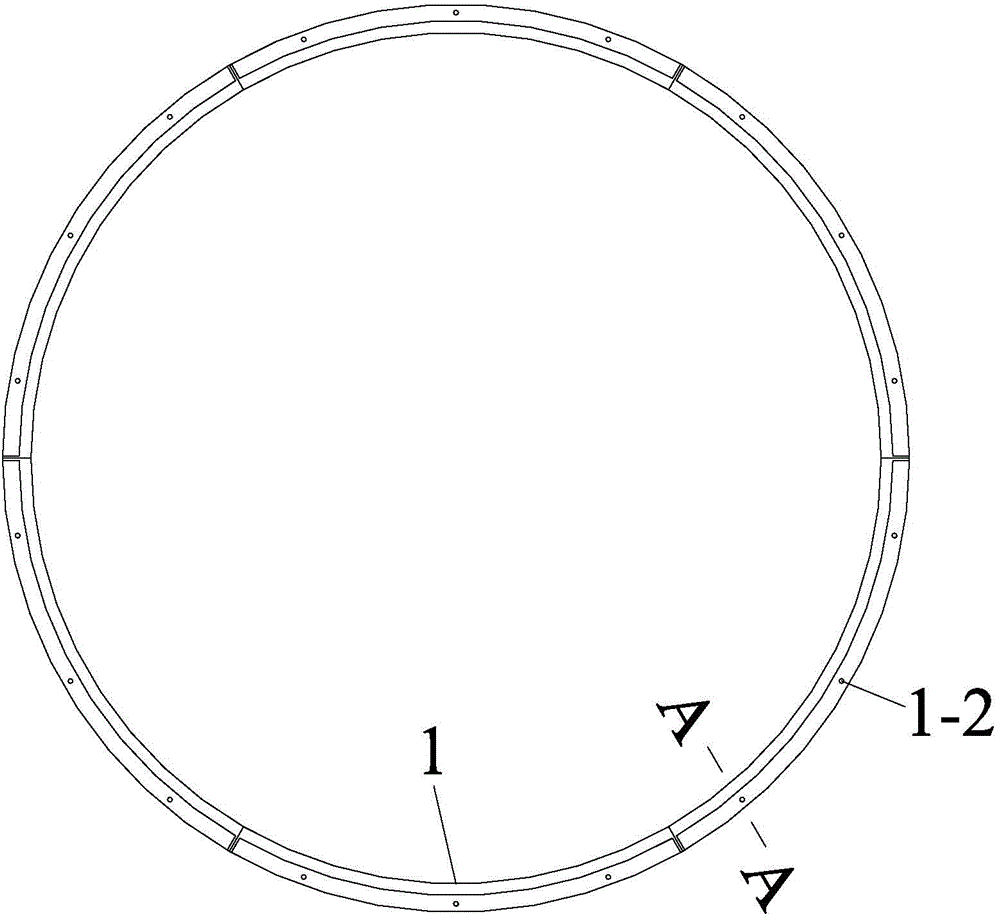

[0055] image 3 and Figure 4 It is the plane and cross-sectional schematic diagram of the bottom form 1, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com