Cement concrete self-restriction contraction stress test approach

A technology of cement concrete and shrinkage stress, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of not taking into account the difference in shrinkage and deformation of concrete specimens, and achieve the effect of low test cost and high test data accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

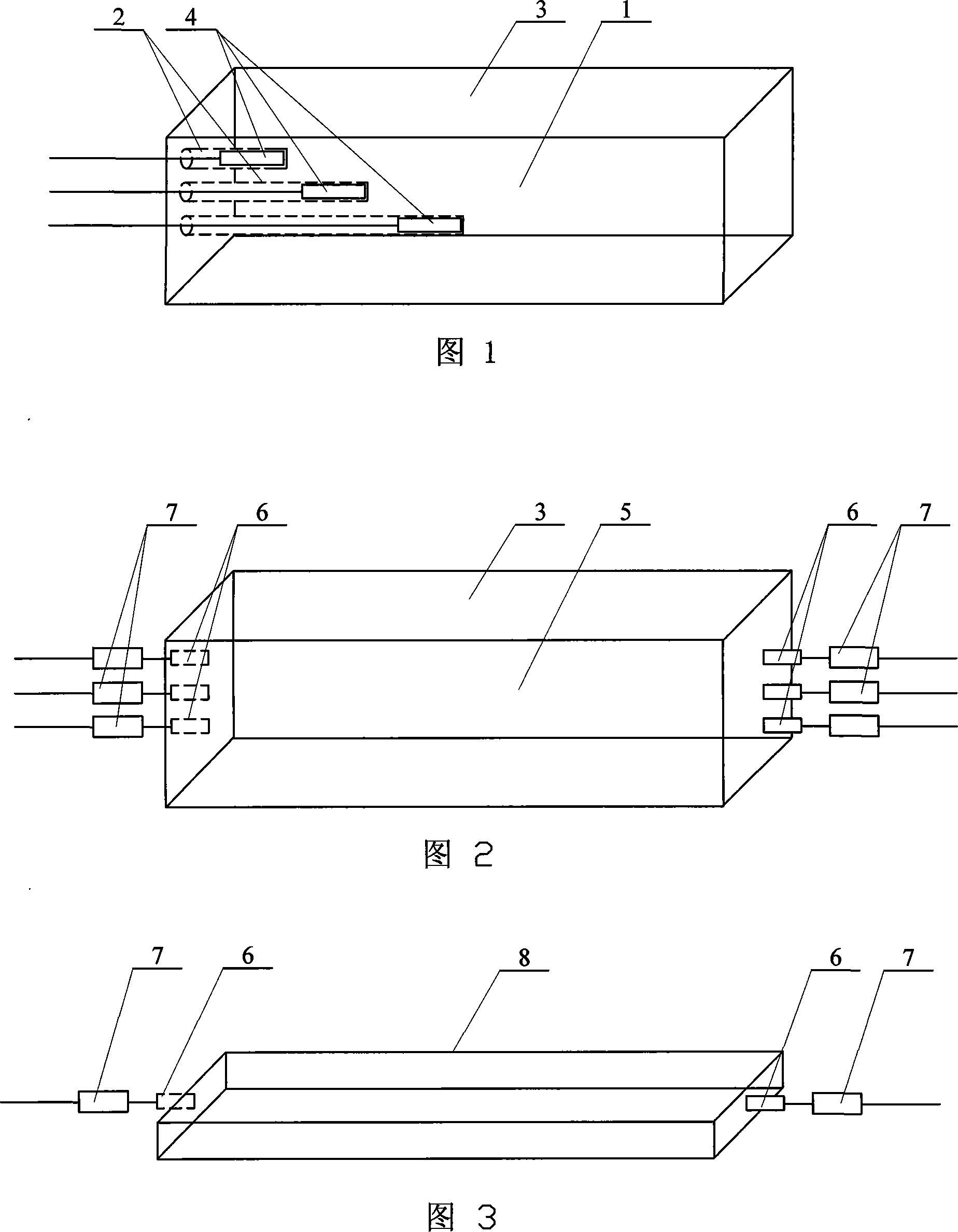

[0008] Specific embodiment one: (referring to Fig. 1~Fig. 3) the method of this embodiment is realized by the following steps: one, make the cement concrete specimen 1 of the first prism shape; During the molding process of the concrete specimen 1, several holes 2 are reserved at different depths from the upper surface 3 of the first prism-shaped cement concrete specimen 1; The other five surfaces of the test piece 1 except the upper surface 3 are all sealed to prevent humidity exchange with the outside world; 4. Put the humidity sensor 4 in the reserved hole 2, and then seal the reserved hole 2; 5. Put the first The cement concrete specimen 1 in the shape of a prism is placed in any test environment with a relative humidity of 30% to 100%, and the relative humidity value RH(h, t) at the depth h from the surface corresponding to each sensor is read at different times t; Six, make the cement concrete specimen 5 of the second prism shape with the same size as the cement concrete...

specific Embodiment approach 2

[0009] Embodiment 2: The number of reserved holes 2 in step 2 of this embodiment is three to ten. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: In step 5 of this embodiment, the reading interval of the time t is 2 to 4 hours. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com