Mining hole packer and hole packing method

A hole sealer and mine-used technology, which is applied in sealing/isolation, earthwork drilling, wellbore/well parts, etc. It can solve the problems of polyurethane sealing failure, complicated sealing process, inconvenient transportation and sealing, etc. , to achieve the effect of improving labor efficiency, improving the quality of sealing holes, and eliminating shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

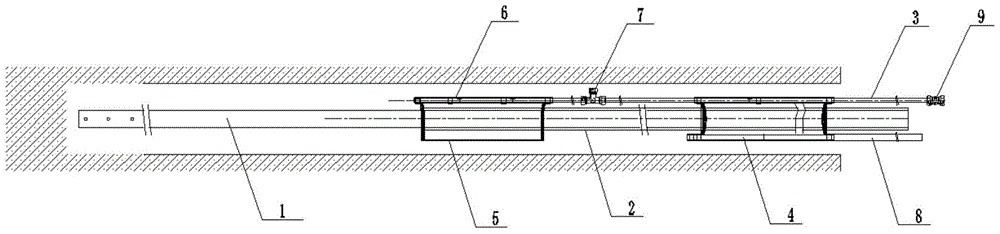

[0050] Such as figure 1 As shown, the mine hole sealer described in the first embodiment includes a drainage casing 2 and a grouting pipe 3, the drainage casing 2 is arranged in the pre-sealing section of the gas drainage pipe 1, and the drainage The casing 2 is sleeved with an orifice pocket 4 near the orifice end, and a hole bottom pocket 5 is sleeved near the bottom end of the hole. The grouting pipe 3 passes through the orifice pocket 4 and the hole bottom pocket 5 and is fixed on the On the pumping casing 2, the end of the grouting pipe 3 is closed, and the grouting pipe 3 is provided with a one-way valve 6 on the position section in the hole bag 4 and the hole bottom bag 5, and the grouting pipe 3 is in the orifice. A burst valve 7 is arranged on the position section between the pouch 4 and the outside of the pouch 5 at the bottom of the hole.

[0051] It also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com