Method for preparing light-transmitting concrete by spinning optical fiber technology

A technology of light-transmitting concrete and optical fibers, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of high brittleness of optical fibers, corrosion of glass cores, large hardening shrinkage, etc. , the effect of low refractive index of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

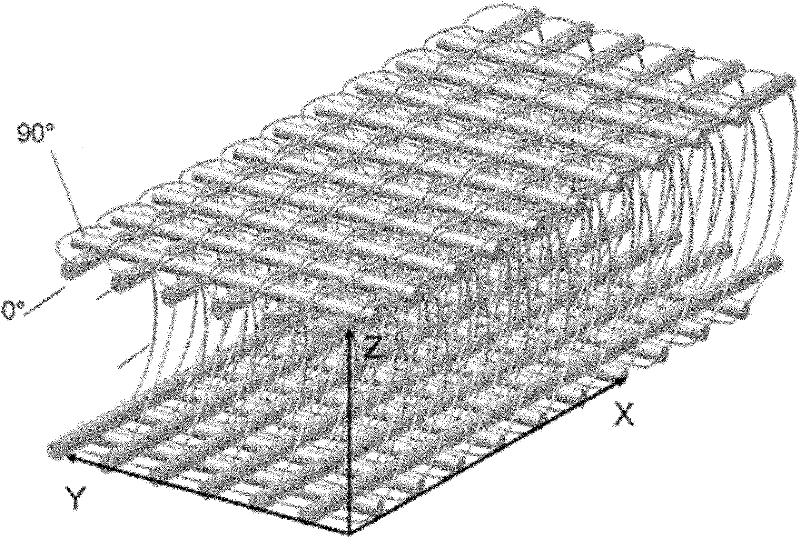

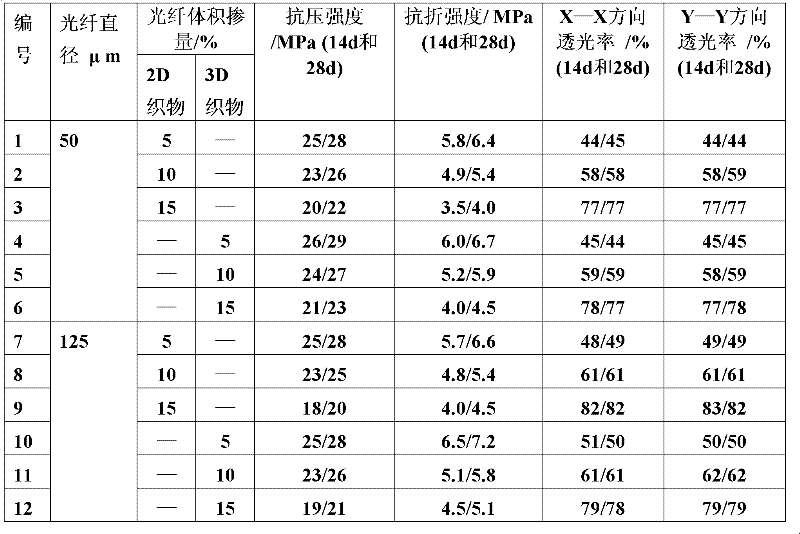

[0029] The raw materials used in Examples 1 and 2 are as follows: the cement is 42.5 sulphoaluminate cement and 52.5 sulphoaluminate cement, both of which have a mass of 1000 g; the maximum particle diameters of the aggregates are 3 mm and 6 mm, respectively, and the masses are 3000 g and 1000 g respectively ; The quality of water is 500g and 300g respectively; The measured mortar consistency is 11cm and 15cm respectively; The strength grades of the prepared cement mortar are 30MPa and 75MPa respectively; / 125μm, fiber fabrics are divided into 3D and 2D fiber fabrics, and the connecting fibers in the Z direction of 3D fabrics are ordinary fibers. The specific processing technology and method are as described above. In addition, the 2D optical fiber fabrics that have been woven are laid in parallel in the test mold and laid in layers. For embodiment 1 and embodiment 2, 3 layers and 5 layers are respectively laid, and the height of each layer is 1 / 4 and 1 / 6 of the height of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com