Method for increasing wind uplift resistance of wood-framed roofs using closed-cell spray polyurethane foam

a technology of polyurethane foam and wood-framed roofs, which is applied in the direction of roofing, building roofs, building repairs, etc., can solve the problems of increasing labor costs, slowing down the foundation and framing stages of construction, and prone to damage of sloped roofs in residential buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0060]This Example details the test procedure to determine the ultimate wind uplift load for roof / wall panels reinforced with a closed-cell spray polyurethane foam. It is based on a slightly modified version of ASTM E330-02 “Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference” using a test wind uplift test arrangement.

Test Panel Construction:

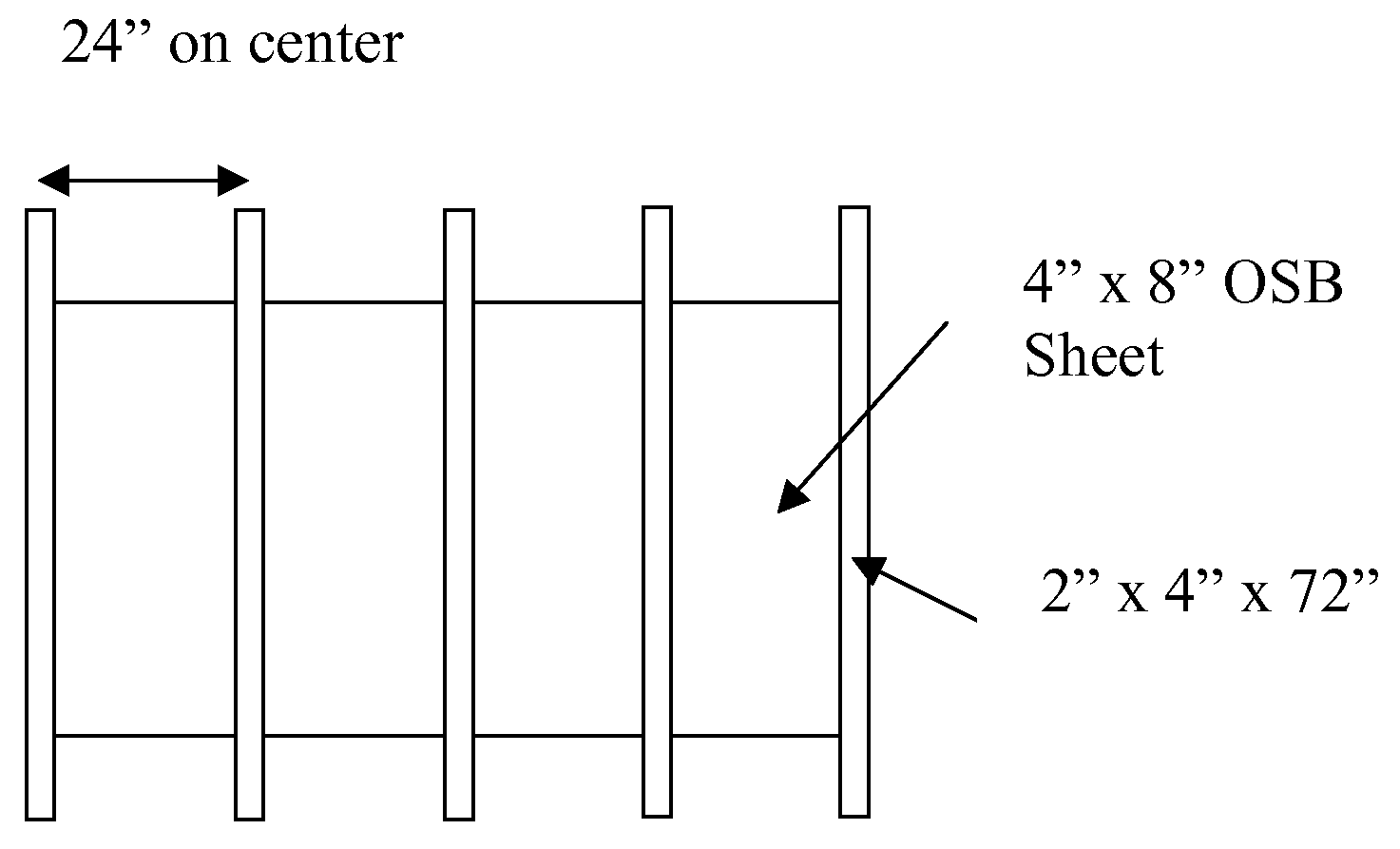

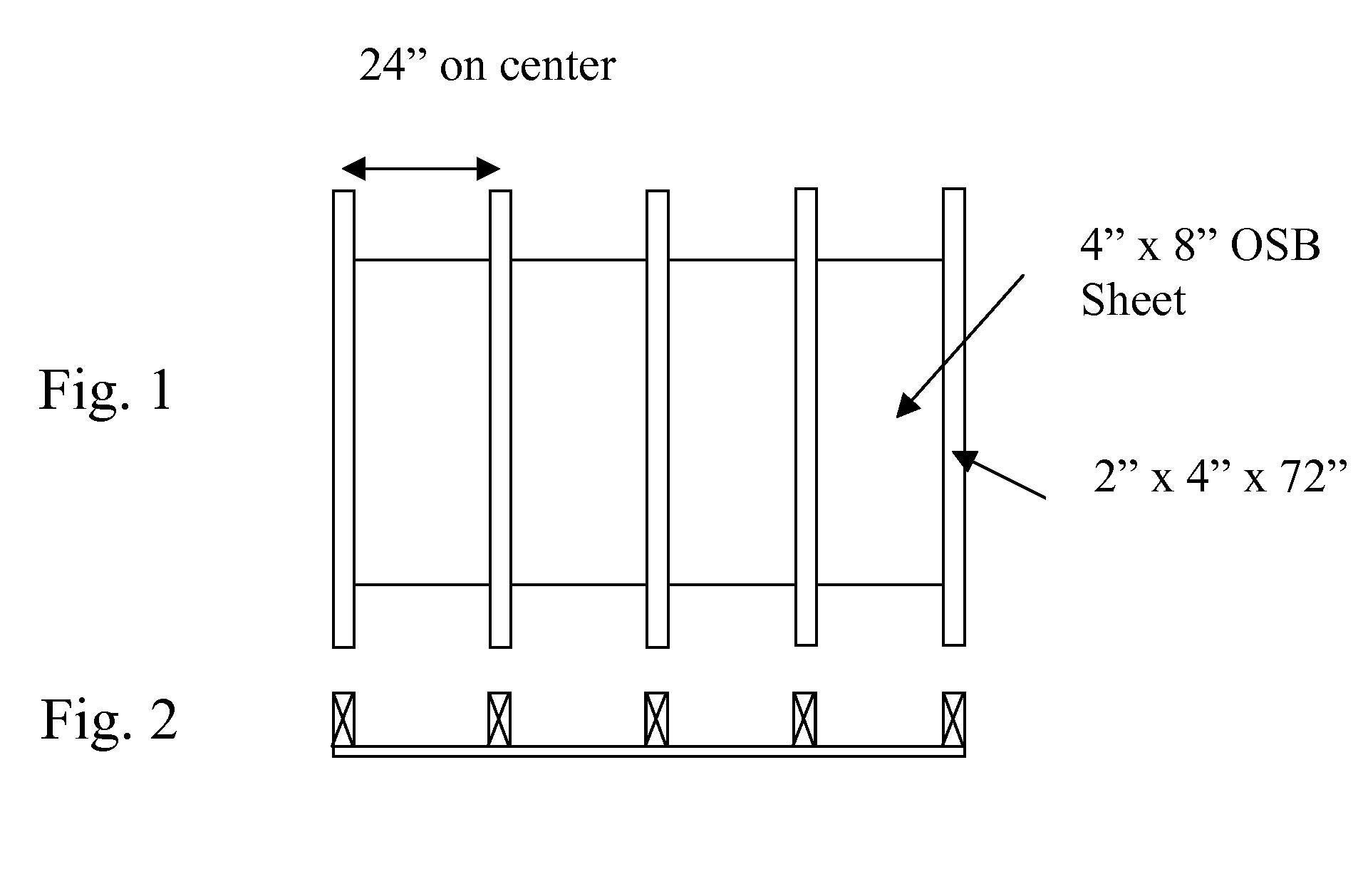

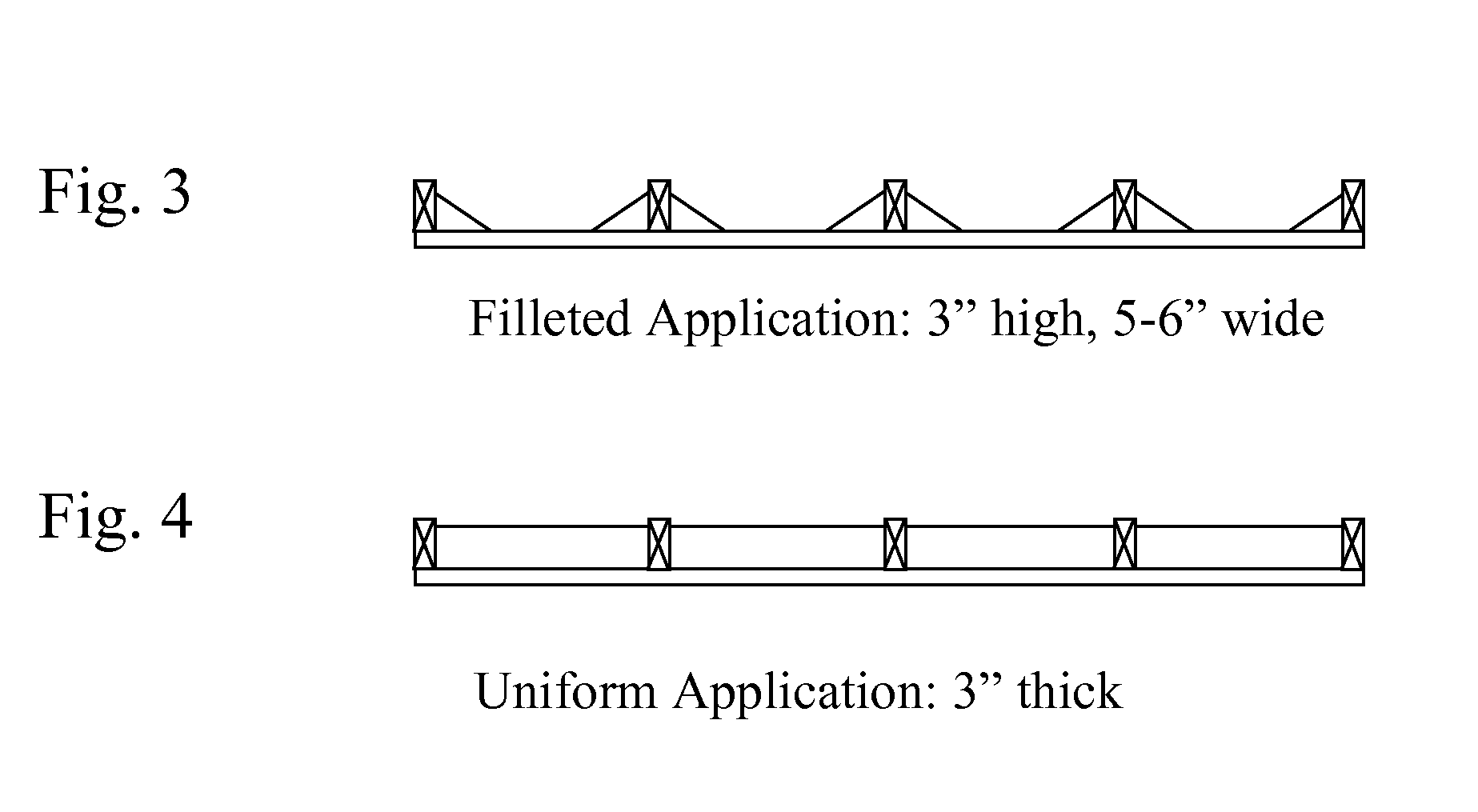

[0061]A structural member is formed according to the configuration shown in FIG. 1 and FIG. 2. The structural test panel comprises an array of five parallel 2″×4″ by 72″ spruce-pine-fir dimensional lumber beams spaced on 24″ centers. A 7 / 16″ oriented strand board (OSB) sheet is fastened to the inside surface of the OSB by nails. The fasteners used were 6d ringshank nails applied using a pneumatic nail gun. Spacing of the ringshank fasteners was 6″ for the two framing members at each end. Spacing of the ringshank nail fasteners on the three inner framing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com