Chemical mechanical polishing solution

A chemical mechanical and polishing liquid technology, applied in the direction of polishing composition containing abrasives, etc., can solve the problem of high tungsten metal, achieve high polishing rate, improve metal surface condition, and inhibit static corrosion

Pending Publication Date: 2021-06-22

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF19 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

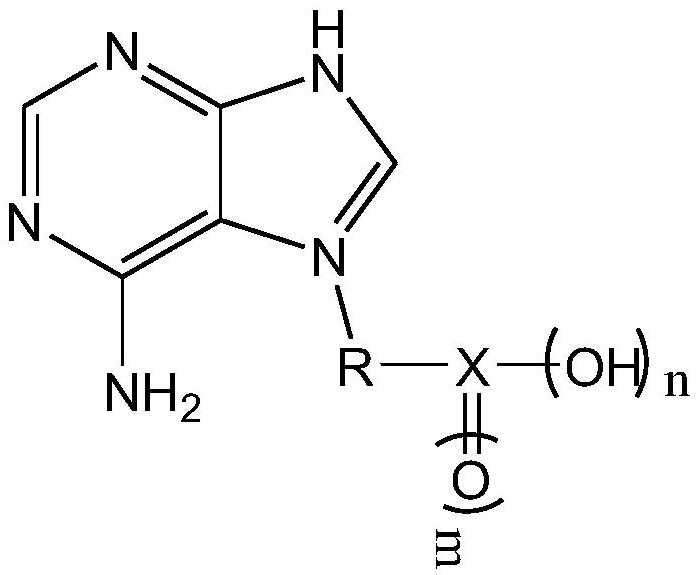

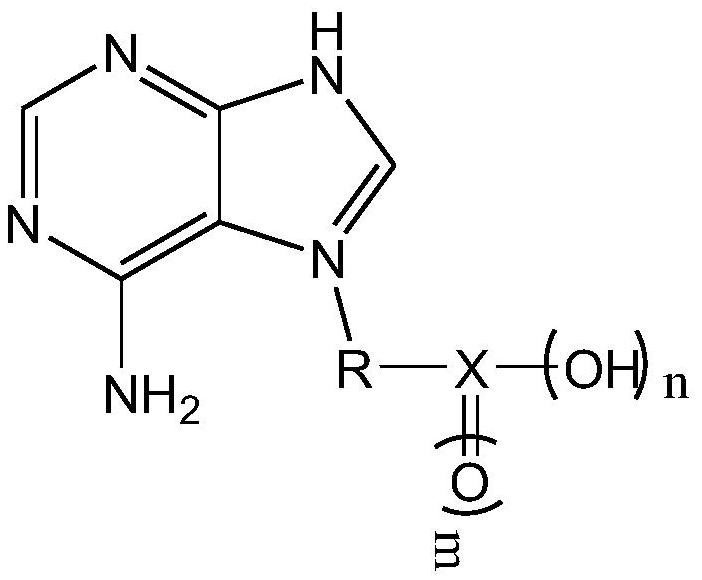

[0005] In order to solve the technical defect that the chemical mechanical polishing fluid in the prior art cannot simultaneously maintain a high polishing rate for tungsten metal, maintain a medium polishing rate for silicon oxide, and efficiently inhibit the static corrosion of tungsten metal, the present invention provides a Chemical mechanical polishing fluid, including: abrasive particles, catalysts, stabilizers, corrosion inhibitors containing adenine organic acid structures, oxidizing agents, water and pH regulators

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

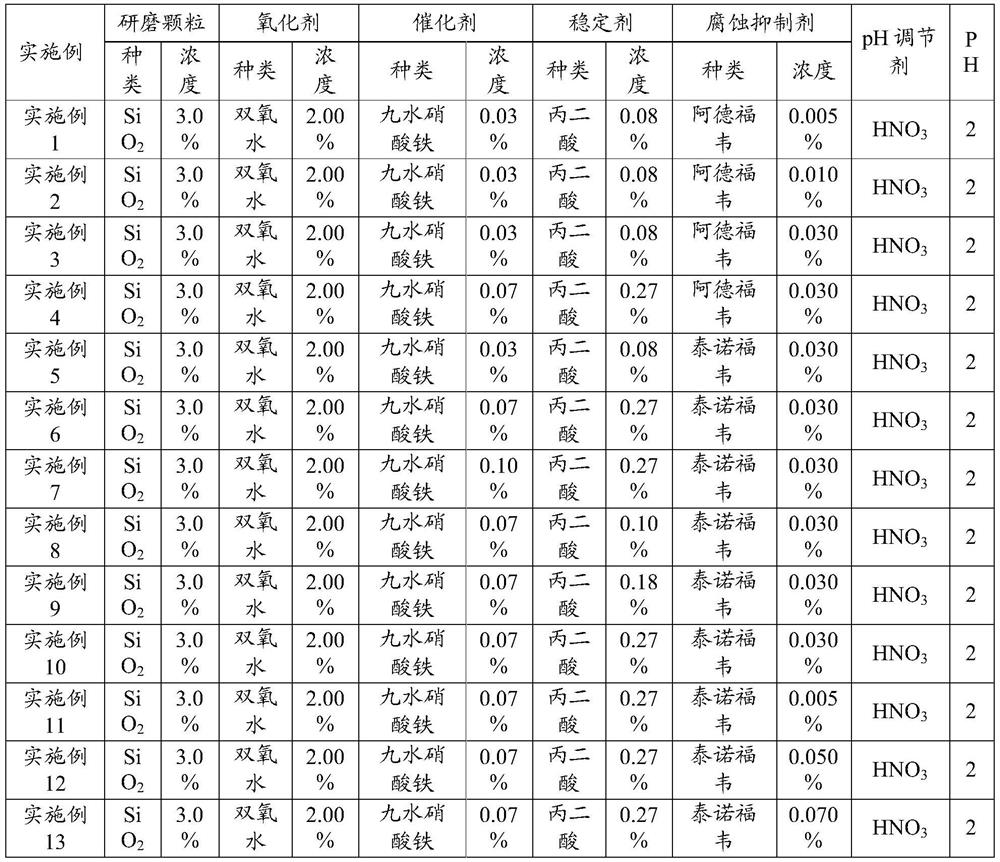

[0040] Specific Examples and Comparative Examples According to the formula given in Table 1, all components were dissolved and mixed evenly, and the mass percentage was made up to 100% with water. Adjust the pH to the desired value with a pH adjuster.

[0041] Table 1. Each component kind and its corresponding concentration in each embodiment and comparative example

[0042]

[0043]

[0044] Effect example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises grinding particles, a catalyst, a stabilizer, a corrosion inhibitor containing an adenine organic acid structure, an oxidizing agent, water and a pH regulator. The metal tungsten and silicon oxide can be polished at the same time, the high polishing rate of the tungsten metal is kept, the medium polishing rate of the silicon oxide is kept, static corrosion of the tungsten metal is efficiently inhibited, and the surface condition of the polished metal is improved.

Description

technical field [0001] The invention relates to a chemical mechanical polishing liquid. Background technique [0002] A modern semiconductor integrated circuit is a collection of millions of tiny components on a substrate, and these components form an interconnection structure through multilayer interconnects to perform corresponding functions. For example, a typical multilayer interconnect structure includes a first metal layer, a dielectric layer, and a second or more metal layers. Each layer structure is prepared by techniques such as physical vapor deposition (PVD), chemical vapor deposition (CVD) and plasma enhanced chemical vapor deposition (PECVD), and then new layers are formed on top of it. As layers of material are deposited and removed, the uppermost surface of the wafer becomes uneven. These unevenness may lead to various defects of the product, so the planarization technology of the conductive layer and the insulating dielectric layer becomes very important. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02C23F3/04C23F11/14

CPCC09G1/02C23F3/04C23F11/149C23F11/14

Inventor 郁夏盈王晨何华锋李星史经深孙金涛

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com