Preparation method for silica-based gallium arsenide material with high quality and low surface roughness

A silicon-based gallium arsenide, low surface technology, applied in the field of silicon-based gallium arsenide material preparation, can solve the problems of low surface roughness and achieve the effect of low polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

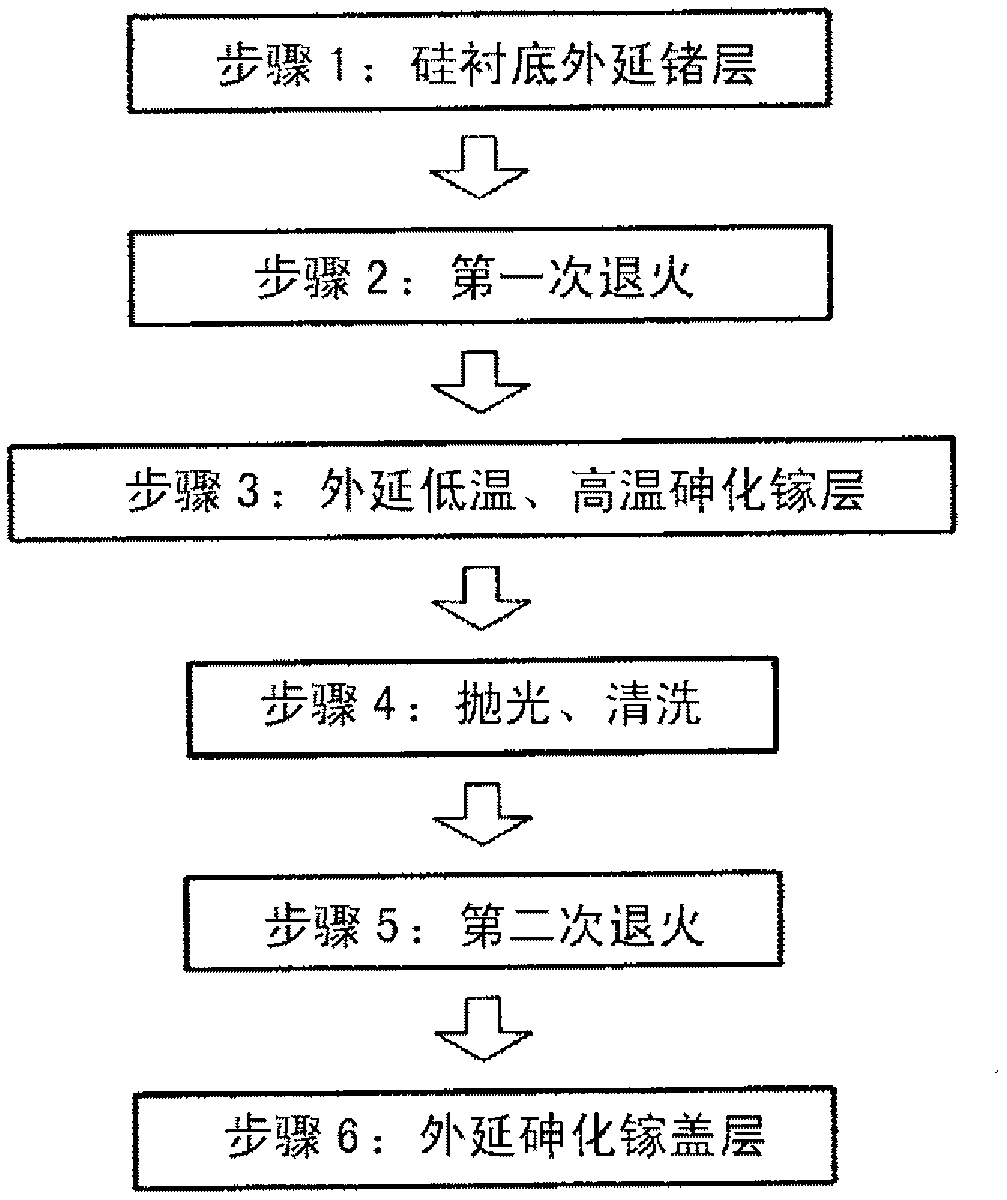

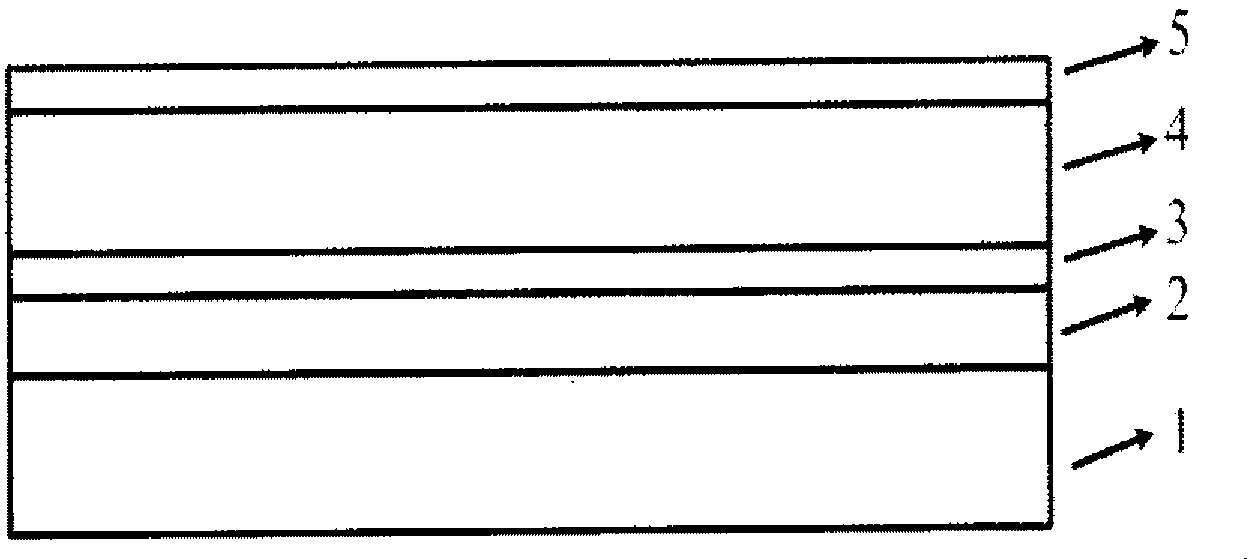

[0021] see figure 1 and figure 2 As shown, the present invention provides a method for preparing a silicon-based gallium arsenide material with high quality and low surface roughness, comprising the following steps:

[0022] Step 1: growing a germanium layer 2 on a silicon substrate 1 . This silicon substrate 1 is the (100) substrate of partial [011] direction 4 °, and size mainly depends on three equipments that need in this method: ultra-low vacuum chemical vapor phase epitaxy (UHVCVD), metal-organic chemical vapor deposition ( MOCVD) and polishing equipment, the size of the epitaxial wafers of the three equipments needs to be consistent, which can be 2 inches to 12 inches, or even larger; the growth of germanium layer 2 adopts UHVCVD, and the low-temperature germanium seed layer and the high-temperature germanium layer are cycled twice. technology, this step is a key step to obtain high-quality gallium arsenide, and the defect density of the germanium layer is required t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com