Preparation method of silicon-based gallium arsenide material with low surface roughness

A silicon-based gallium arsenide, roughness technology, applied in chemical instruments and methods, from chemical reactive gases, semiconductor/solid-state device manufacturing, etc., can solve problems such as low surface roughness, and achieve the effect of low polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

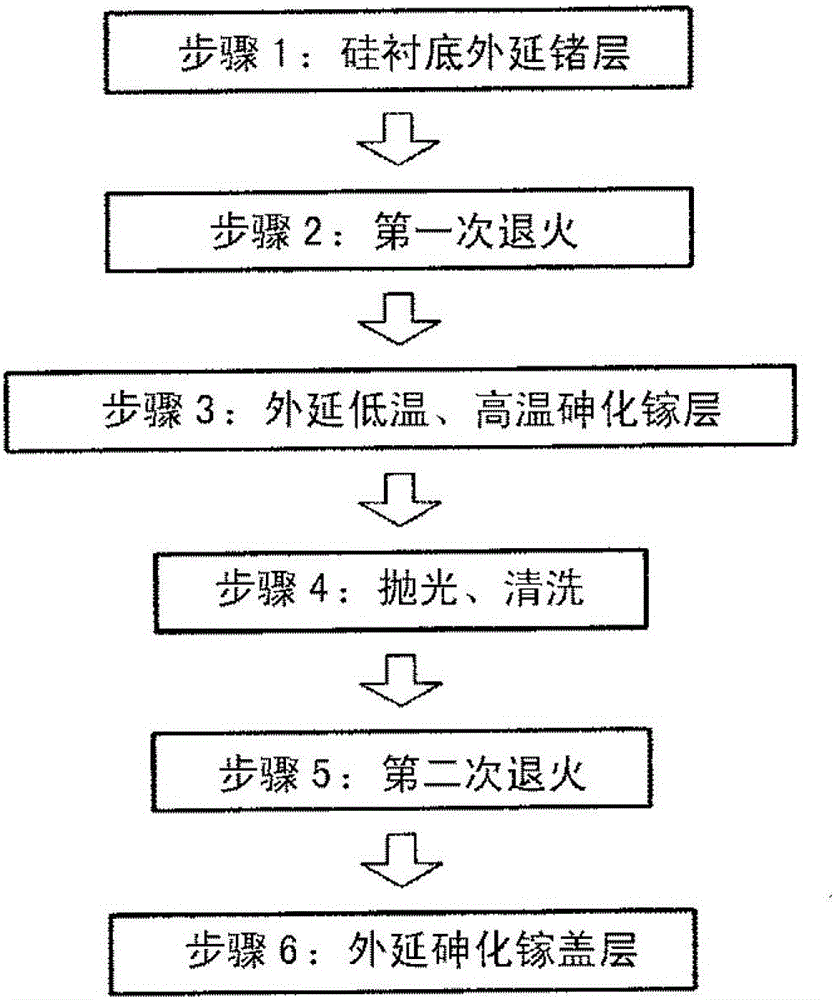

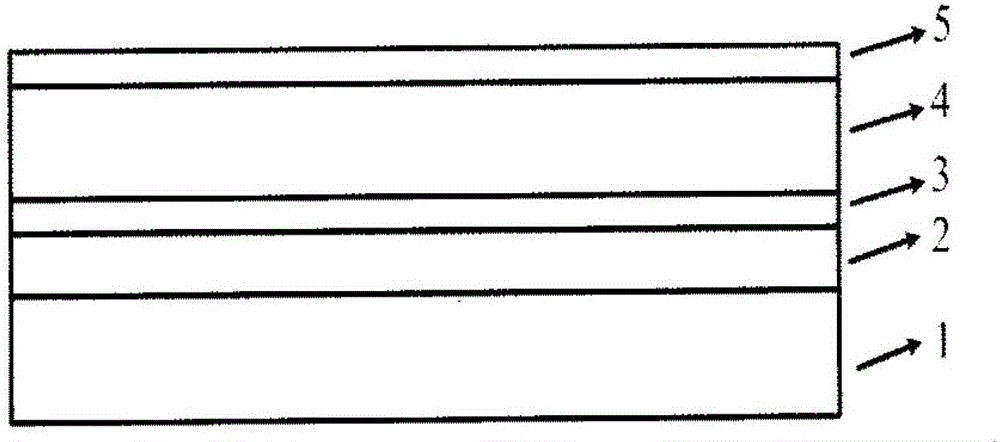

[0021] see figure 1 and figure 2 As shown, the present invention provides a method for preparing a silicon-based gallium arsenide material with low surface roughness, comprising the following steps:

[0022] Step 1: growing a germanium layer 2 on a silicon substrate 1 . This silicon substrate 1 is the (100) substrate of partial [011] direction 4 °, and size mainly depends on three equipments that need in this method: ultra-low vacuum chemical vapor phase epitaxy (UHVCVD), metal-organic chemical vapor deposition ( MOCVD) and polishing equipment, the size of the epitaxial wafers of the three equipments needs to be consistent, which can be 2 inches to 12 inches, or even larger; the growth of germanium layer 2 adopts UHVCVD, and the low-temperature germanium seed layer and the high-temperature germanium layer are cycled twice. technology, this step is a key step to obtain gallium arsenide, and the defect density of the germanium layer is required to be 1E5cm -2 Below, the roug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com