Sparkle beads producing cardamon green firework effect, and manufacturing method thereof

A bright pearl and cardamom technology, applied to explosives and other fields, can solve the problem of fewer colors and varieties of fireworks shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

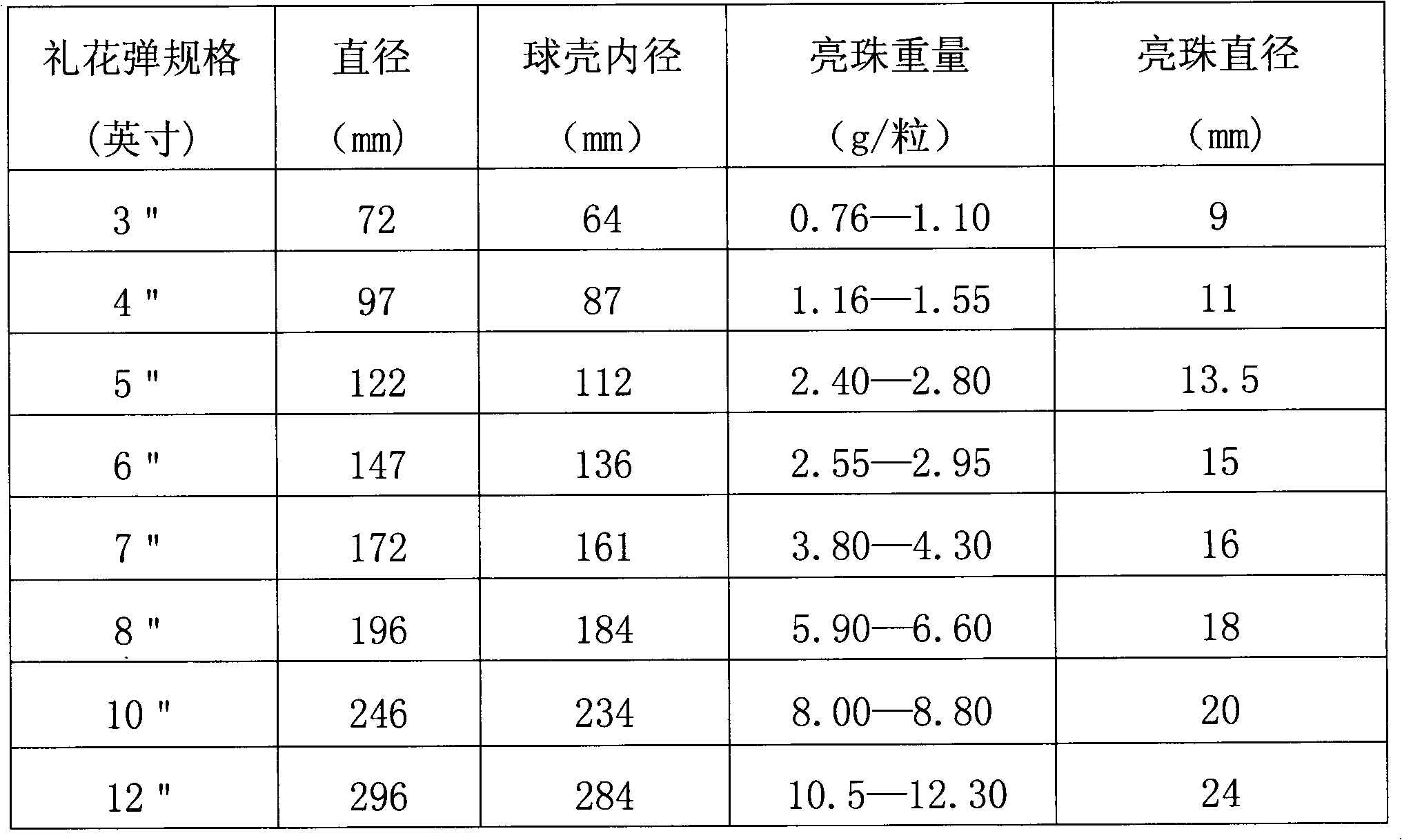

[0024] Example 1 The present invention has three kinds of bright pearls with optimal weight ratios. The inner core is made according to Table 1, and the main raw materials of the inner core are respectively crushed and sieved with a 100-120 mesh sieve, and then the main raw materials of the inner core are mixed and stirred and passed through a sieve. Sieve, then put into a granulator and roll into a spherical shape, the diameter of the inner core of the bright beads made is 2mm smaller than the diameter of the bright beads listed in Table 3; make the ignition layer according to Table 2, and use 100 -Sieve through a 120-mesh sieve, then mix and stir the main raw materials of the above-mentioned ignition layer, and then sieve. After the inner core is rolled to meet the specification requirements, add the main raw material mixture of the ignition agent and roll on the outside of the sphere to form a covering layer with a thickness of 1mm; The bright pearl of the present invention ...

Embodiment 2

[0025] Embodiment 2 The manufacturing method of bright beads of the present invention comprises the following process steps:

[0026] 1) Weighing: According to Table 1, the various main raw materials required for the inner core are classified and placed according to the weight ratio of different formulas; according to Table 2, the various main raw materials required for the ignition layer are proportioned according to different formulas classification placement;

[0027] 2) Raw material pulverization: each main raw material is pulverized separately through a pulverizer, and sieved once with a 100-120 mesh sieve;

[0028] 3) Mixing and stirring: mix and stir various main raw material powders according to the proportion (see Table 1 and Table 2), and sieve through a 100-120 mesh sieve;

[0029] 4) Molding: Put the main raw materials of the mixed inner core into the granulator and roll into shape. The inner diameter of the bright beads made is 2mm smaller than the diameter of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com