Sludge treatment system and method thereof

一种污泥处理、污泥的技术,应用在污泥处理、生物污泥处理、水/污泥/污水处理等方向,能够解决污泥与臭氧不能充分接触、难大规模推广应用、臭氧投放比例高等问题,达到提高氧化效率、降低能耗、减少投加量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

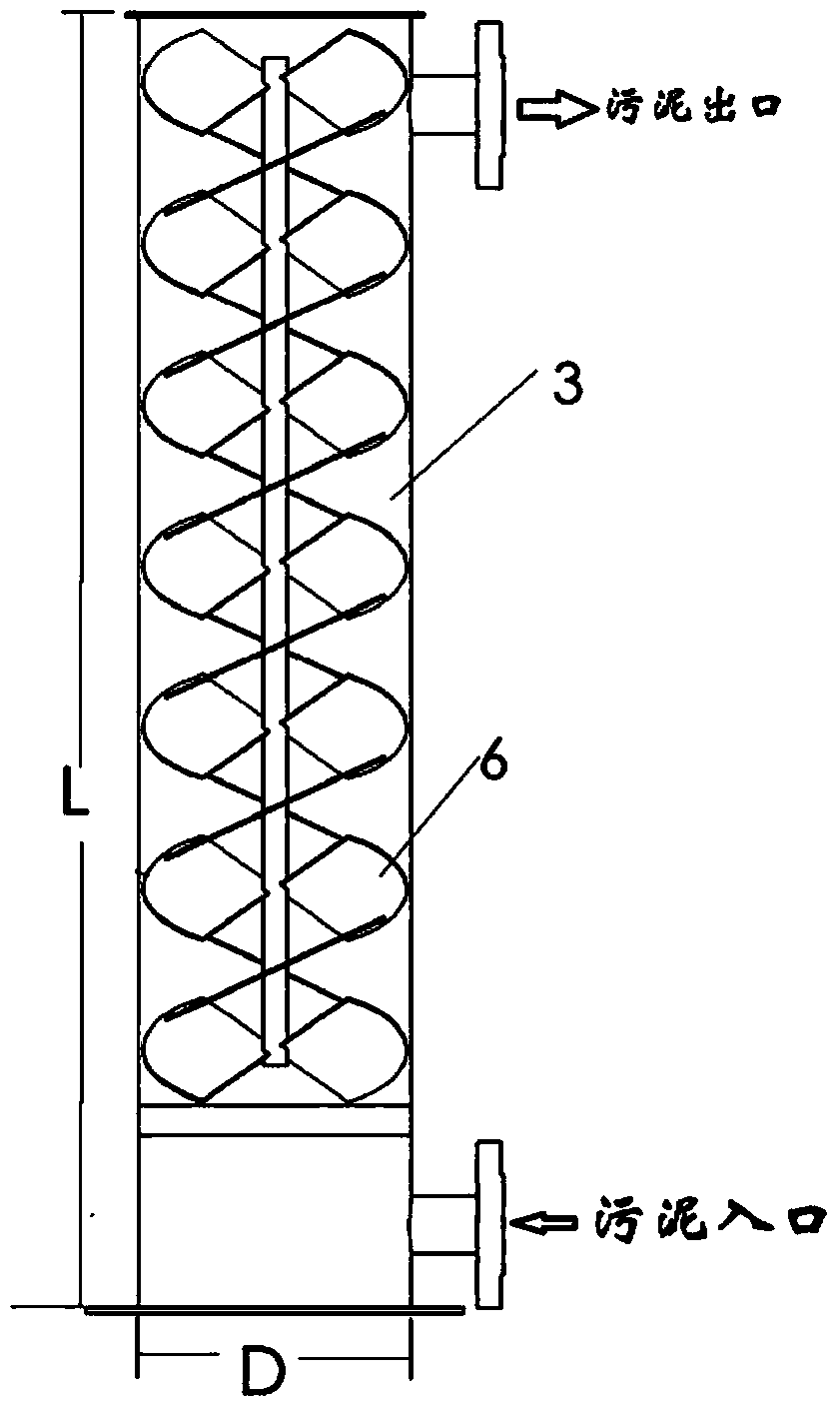

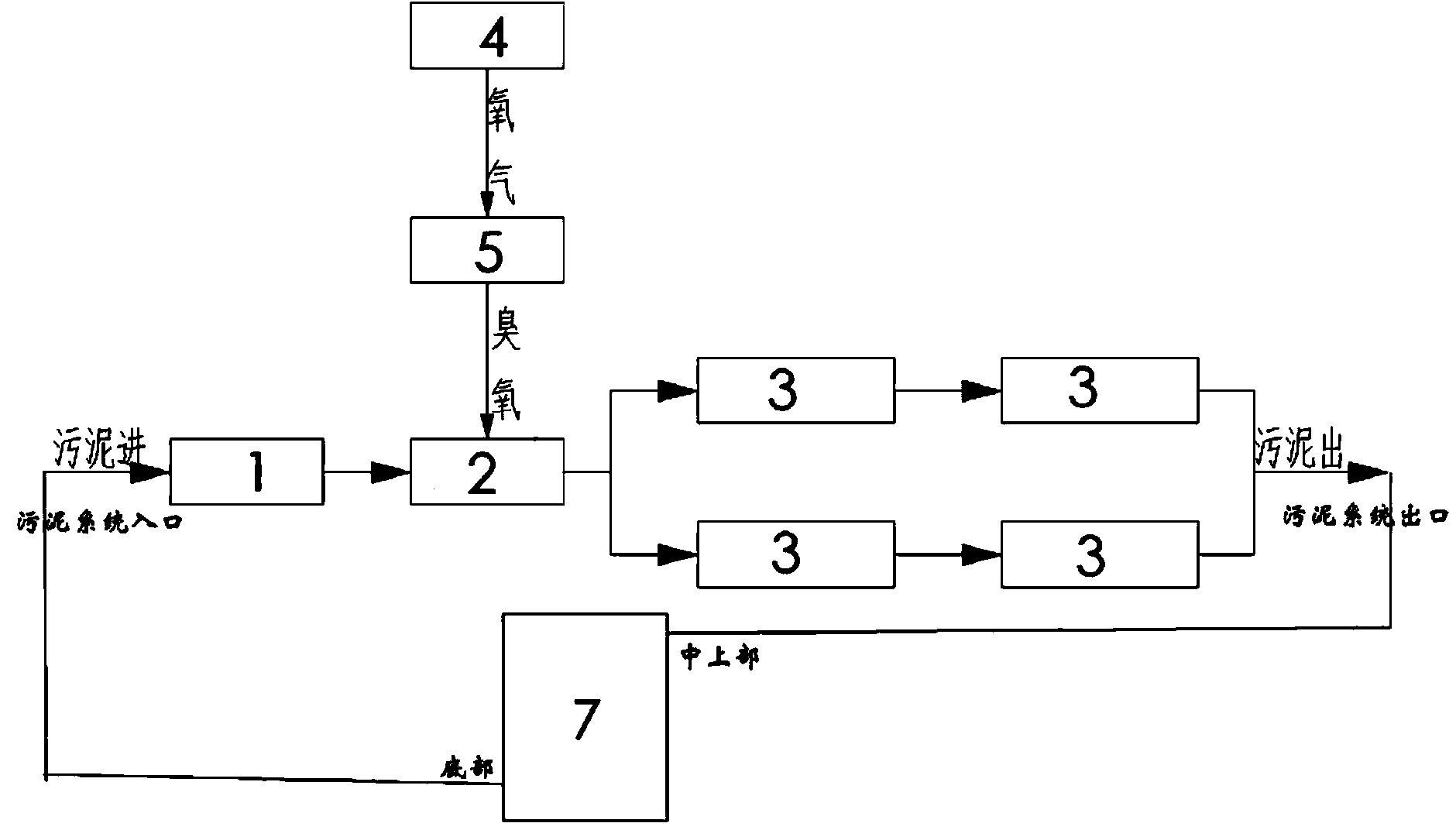

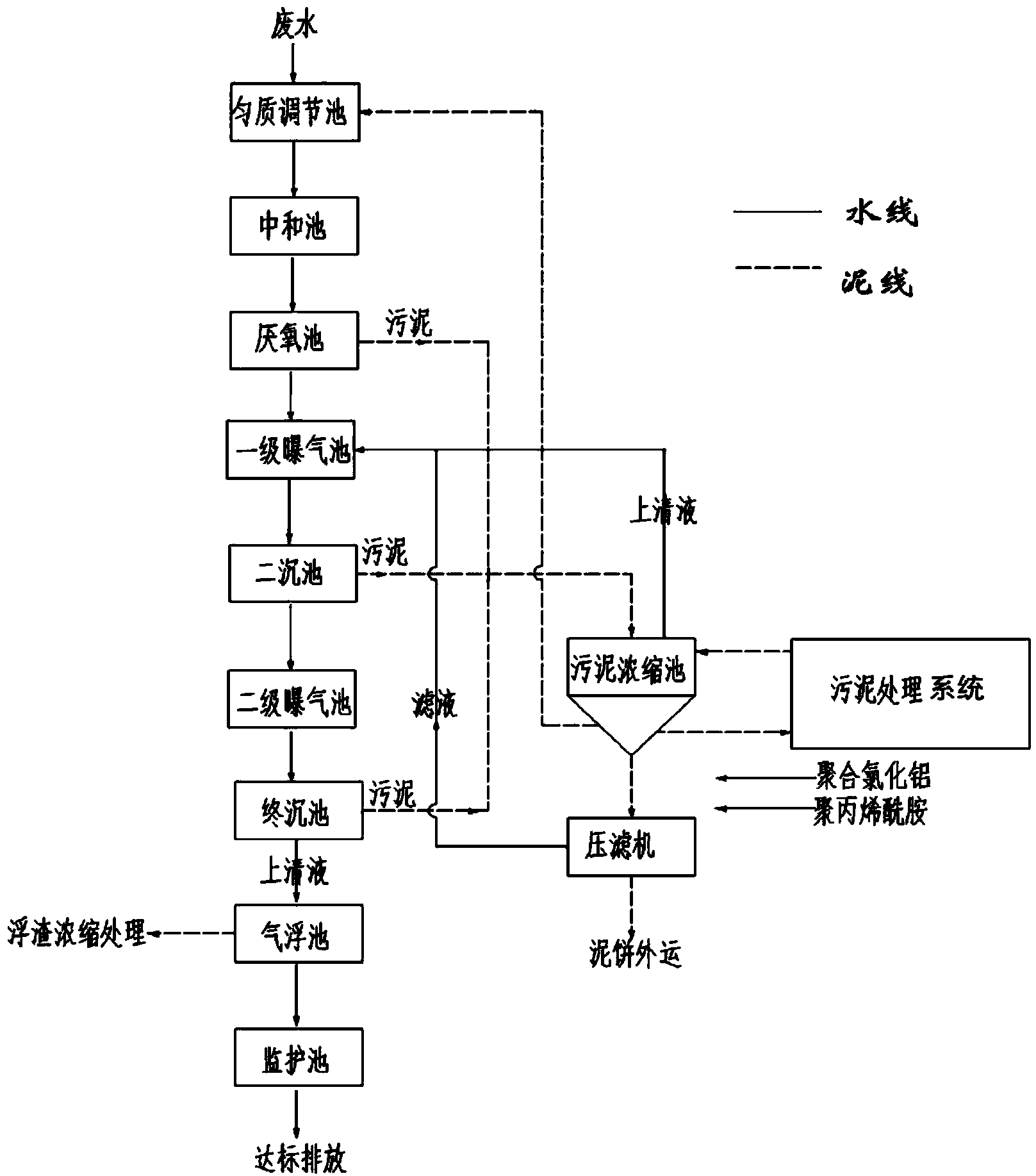

[0035] Such as figure 1 and figure 2 As shown, a sludge treatment system of the present invention is characterized in that: the sludge treatment system includes a pump 1 with a flow rate of 8m3 / h, an ozone generator, an ejector 2 and a pipeline connected sequentially through a pipeline Reactor 3, the ozone generating device is used to provide ozone into the pipeline reactor 3 to achieve sufficient contact between ozone and sludge.

[0036] The ejector 2 is a Venturi mixer.

[0037] Described ozone generator is provided with the oxygen generator 4 of 1 60L / min and the ozone machine 5 of 1 240g / h connected by pipeline;

[0038] There are four pipeline reactors 3, and the pipeline reactors 3 are connected in parallel or in series through pipelines;

[0039] The inner surface of the pipeline reactor 3 is coated with a catalyst that can catalyze ozone into hydroxyl radicals, further improving the oxidation efficiency of ozone.

[0040] The lower part of the pipe reactor 3 is p...

Embodiment 2

[0062] Such as figure 1 and figure 2 As shown, a sludge treatment system of the present invention is characterized in that: the sludge treatment system includes a pump 1, an ozone generating device, an ejector 2 and a pipeline reaction tube with a flow rate of 16m3 / h connected sequentially through pipelines. device 3, the ozone generating device is used to provide ozone into the pipeline reactor 3, realize sufficient contact between ozone and sludge, and realize solid-liquid separation at the same time.

[0063] Described ozone generator is provided with the oxygen generator 4 of 1 140L / min and the ozone machine 5 of 1 480g / h connected by pipeline;

[0064] There are 8 pipeline reactors 3, and the pipeline reactors 3 are connected in series in groups of 4, and then two groups are connected in parallel;

[0065] The inner surface of the pipeline reactor 3 is coated with a catalyst that can catalyze ozone into hydroxyl radicals, further improving the oxidation efficiency of o...

Embodiment 3

[0090] Such as figure 1 and figure 2 As shown, a sludge treatment system of the present invention is characterized in that: the sludge treatment system includes a pump 1, an ozone generating device, an ejector 2 and a pipeline reaction tube with a flow rate of 2m3 / h connected sequentially through pipelines. device 3, the ozone generating device is used to provide ozone into the pipeline reactor 3, realize sufficient contact between ozone and sludge, and realize solid-liquid separation at the same time.

[0091] Described ozone generator is provided with the oxygen generator 4 of 1 5L / min and the ozone machine 5 of 1 30g / h connected by pipeline;

[0092] There are four pipeline reactors 3, and the pipeline reactors 3 are connected in parallel or in series through pipelines;

[0093] The inner surface of the pipeline reactor 3 is coated with a catalyst that can catalyze ozone into hydroxyl radicals, further improving the oxidation efficiency of ozone.

[0094] The lower part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com