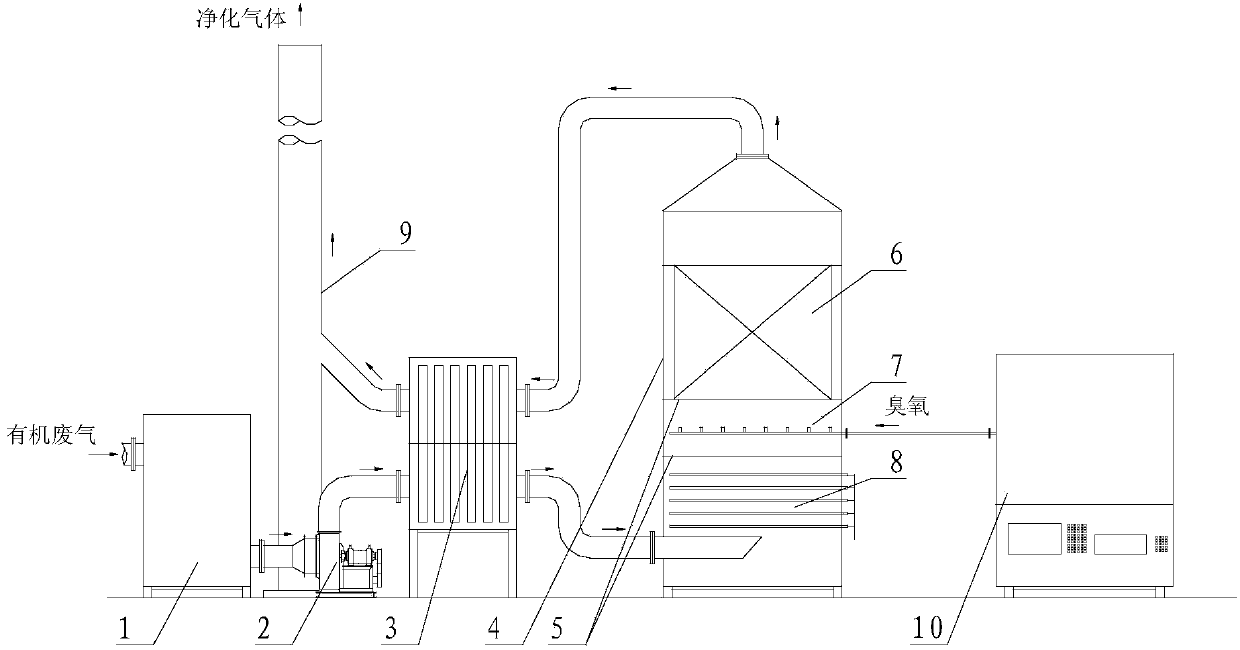

Device and method for treating organic waste gas by catalysis and ozonation

An organic waste gas, catalytic oxidation technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of poor reaction selectivity between ozone and organic matter, difficult to achieve removal effect, and inability to decompose organic matter, and save energy consumption. , The effect of preventing secondary pollution and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A certain organic waste gas containing low-concentration benzene series is processed by the above-mentioned device and process of the present invention, and enters the catalytic oxidation device through the induced draft fan. The catalyst carrier is γ-type alumina, the active component is manganese oxide, and the load is about 5%. The concentrations of ozone and benzene series are 70mg / m 3 and 15mg / m 3 . It can react at room temperature, and the purification efficiency of benzene, toluene, and p-xylene can reach 75%, 84%, and 88% respectively; when the reaction temperature is raised above 90°C, the purification efficiency of benzene, toluene, and p-xylene can reach 95% %above.

[0055] The above-mentioned organic waste gas containing low-concentration benzene series also adopts the above-mentioned device and process of the present invention. When no catalyst is placed, the purification efficiency of ozone to benzene, toluene and p-xylene can be ignored at room temper...

Embodiment 2

[0057] Another certain organic waste gas containing benzene, adopts the above-mentioned device and process of the present invention, enters the heat exchanger through the induced draft fan after pretreatment, and then enters the catalytic oxidation device for treatment. The catalyst carrier is γ-type alumina, the active component is a mixture of cobalt oxide and chromium oxide, the ratio of cobalt to chromium is 4:1, and the load is 8.5-10%. The concentration ratio of ozone to benzene is about 10:1, and when the reaction temperature is 100-150°C, the purification efficiency of benzene is about 75%-96%.

[0058] The above-mentioned same benzene-containing organic waste gas uses the same type of treatment device and catalyst. When ozone is not used, the reaction temperature needs to be raised to 300-360°C, and the purification efficiency of benzene is about 65%-92%.

[0059] By comparison, the presence of ozone can effectively reduce the catalytic reaction temperature of benzene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com