Microwave electro-Fenton method for processing organic wastewater and device thereof

A technology of organic wastewater and Fenton's method, which is applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problem of weak oxidation and degradation ability of pollutants, limited working life and easy pollution of electrodes and other problems, to achieve ideal degradation effect, wide potential window, and promote the effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

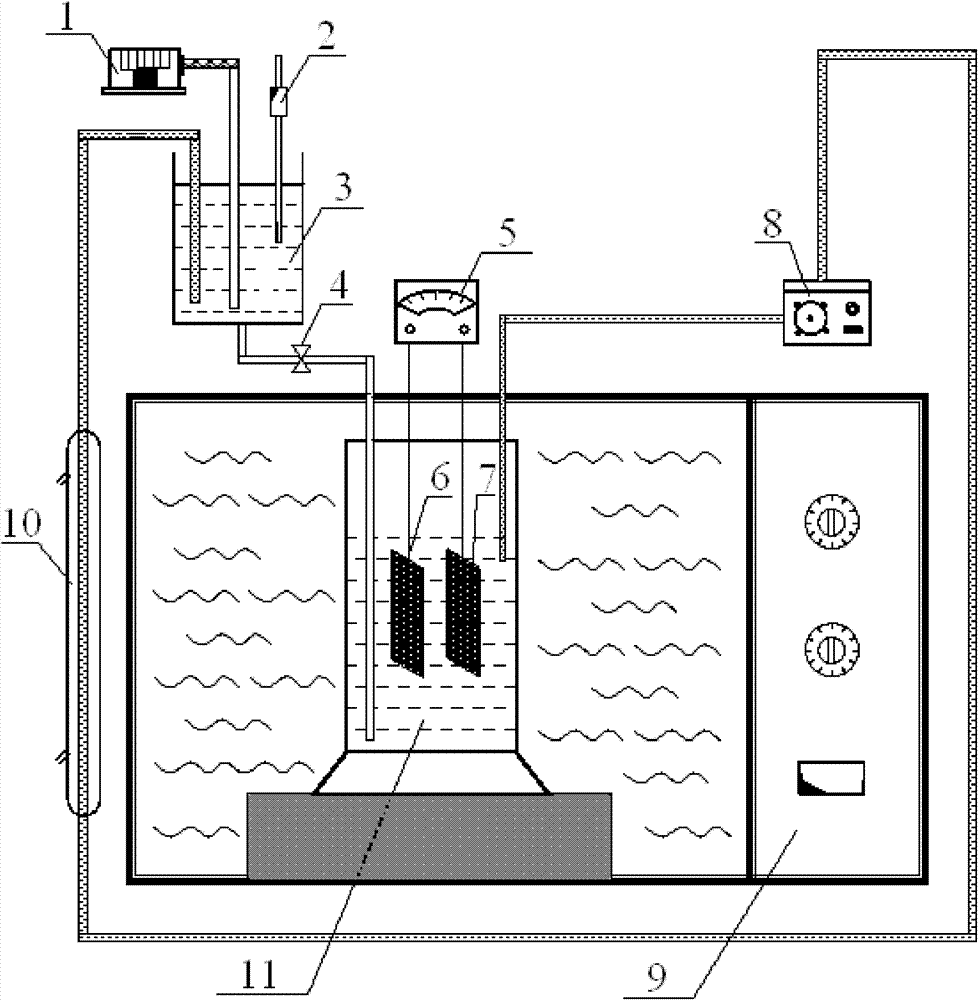

[0025] A device for the microwave electro-Fenton method of treating waste water, its structure is shown in Figure 3, the device includes an air aeration device 1, a thermometer 2, a storage pool 3, a flow meter 4, a DC power supply 5, a cathode 6, an anode 7. Composed of a peristaltic pump 8, a microwave oven 9, a condenser tube 10 and a reactor 11. The anode 7 adopts a boron-doped diamond film electrode, and the cathode 6 adopts a titanium electrode, wherein: wherein the cathode 6 and the anode 7 are respectively inserted into the reactor 11, the anode 7 and the cathode 6 are connected through a DC power supply 5, and the reactor 11 is placed in a microwave oven 9. One end of the pipeline is inserted into the reactor 11, and the other end passes through the peristaltic pump 8, the flow meter 4, and the condenser tube 10 in sequence, and is inserted into the storage pool 3, so as to realize flow cycle sample introduction and degradation. The aeration device 1 and the thermomet...

Embodiment 2

[0027] Using methyl orange wastewater as the water sample to be treated

[0028] The TOC of the water sample is 300mg / L, the pH is 3.0, the Fe 2+ is 1.0mmol / L, the concentration of supporting electrolyte sodium sulfate is 0.05mol / L, and the volume is 100ml. The area of boron-doped diamond film electrode and titanium electrode as anode and cathode respectively is 3.5cm 2 , the electrode spacing is 1cm, the current density is 10mA / cm 2 Carry out constant current degradation, the microwave frequency is 2450MHz, and the power is 120W. The effects were compared with the electro-Fenton degradation alone as a comparative test. The TOC removal rate was only 38.5% when electro-Fenton oxidation degradation was performed for 3 hours alone; the removal rate was greatly increased to 95.8% when microwave-enhanced boron-doped diamond film electrode electro-TOC oxidation technology was used for 3 hours, and the removal rate increased by 148.8%.

Embodiment 3

[0030] Use 2,4-dichlorophenoxyacetic acid wastewater as the water sample to be treated

[0031] COD of water samples Cr 200mg / L, pH 3.0, Fe 2+ is 1.0mmol / L, the concentration of supporting electrolyte sodium sulfate is 0.05mol / L, and the volume is 100ml. The area of boron-doped diamond film electrode and titanium electrode as anode and cathode respectively is 5.5cm 2 , the electrode spacing is 1cm, the current density is 20mA / cm 2 Carry out constant current degradation, the microwave frequency is 2450MHz, and the power is 120W. Use electro-Fenton degradation alone as a comparative test to compare the effects. COD of electro-fenton oxidation degradation for 3 hours Cr The removal rate was only 65%; the removal rate was greatly increased to 98% when the microwave-enhanced boron-doped diamond film electrode electrochemical oxidation technology was used for 3 hours, and the removal rate increased by 50.8%.

[0032] In large-scale treatment equipment for practical applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com