Bottom mud repair and treatment material for urban black and odorous river channel and preparing method of bottom mud repair and treatment material

A technology for river bottom mud and treatment materials, applied in the direction of biological sludge treatment, etc., can solve the problems of inability to remove pollutants, reduce microorganisms, and high cost, and achieve the effects of reducing dust hazards, improving catalytic efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Laboratory static simulation experiment

[0034] Take the bottom mud from the black and smelly river course and put it into a 1L beaker with a height of 4cm and press 1kg / m 2 Add restoration materials and mix well, take river water filtered through 0.45μm as overlying water. The material preparation process is the same as above, the composition weight ratio: CaO 2 Powder 40 parts by mass, MgO 2 30 parts by mass of powder, 10 parts by mass of modified attapulgite clay, 25 parts by mass of EM bacteria dry powder (EM bacteria powder was purchased from Cangzhou Huayu Biotechnology Co., Ltd.), 5 parts by mass of modified nano titanium dioxide. After 10 days, the sediment was taken for testing. The results are shown in Table 2.

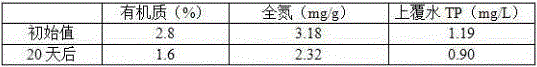

[0035] Table 2 Index Comparison

[0036]

Embodiment 2

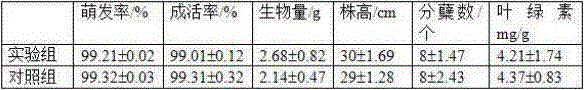

[0037] Example 2: Black and smelly river simulation experiment

[0038] Use plexiglass as a material to make a cuboid box as a simulated river. The box is 1m long, 0.3m wide, and 0.3m high. Excavate an appropriate amount of black and odorous river sediment and lay it on the bottom of the simulated river. The laying thickness is 0.1m, and the black and odorous river is extracted. The river water is discharged into the simulated river channel as the overlying water, the water level is maintained at 0.2m, and the inflow flow rate is 0.03m 3 / d, after simulating the stable operation of the river channel, the sediment is repaired with repair materials. The material preparation process is the same as above, and the composition weight ratio: CaO2 powder 42 parts by mass, MgO2 powder 25 parts by mass, modified attapulgite clay 6 parts by mass, EM bacteria dry powder 20 parts by mass, zeolite powder 5 parts by mass, 2 parts by mass of modified nano-titanium dioxide, and 1 part by mass...

Embodiment 3

[0041] Example 3: A certain river has a total length of 1000m and a water area of 30,000m 2 , water storage capacity 20,000 m 3 , the water source is mainly rainwater, and domestic sewage is discharged in, and the flow rate is slow, which belongs to a typical urban black and smelly river. The river channel is repaired with sediment, and the dosage ratio is 1kg / m 2 , Restoration material composition weight ratio: CaO2 Powder 45 mass fraction, MgO 2 26 mass fractions of powder, 5 mass fractions of modified attapulgite clay, 23 mass fractions of EM bacteria dry powder, and 1 mass fraction of modified nano titanium dioxide. One month after adding the repair material, the odor situation improved significantly. The test results of the bottom mud are shown in Table 4.

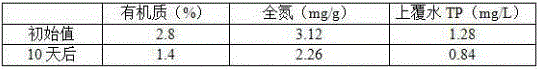

[0042] Table 4 Index Comparison

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com