Preparation method of waterproof biomass molded coal binder

The technology of binder and biomass is applied in the field of preparation of waterproof biomass briquette binder, which can solve the problems of high residual carbon content and poor waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

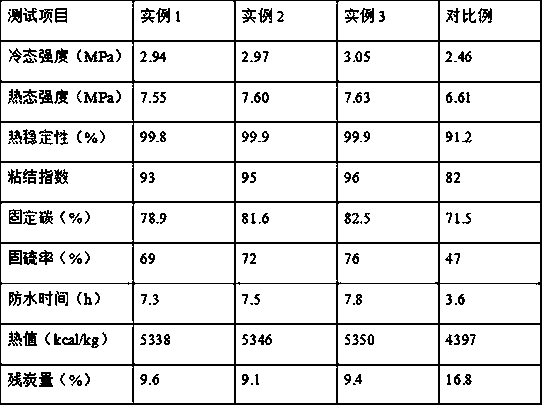

Examples

example 1

[0026]Mix soybean oil and 90% ethanol solution with a mass fraction of 10:3 into a three-necked flask equipped with a stirrer and a thermometer, then put the three-necked flask into a water bath, and raise the temperature of the water bath to 60°C. Start the agitator, stir and mix at a speed of 300r / min for 30min to obtain a mixed solution; transfer the mixed solution into a separatory funnel, let stand at a temperature of 4°C for 3h, separate and obtain the upper oil phase and the lower ethanol phase respectively, Put the ethanol phase in the lower layer into a rotary evaporator, and concentrate it by rotary evaporation at 40°C for 30 minutes to obtain a concentrated solution for later use; mix the upper oil phase and activated sludge from a sewage plant at a mass ratio of 5:1 and put it into a fermenter. Seal the mouth of the tank and ferment for 7 days at 35°C. After the fermentation is over, the fermentation product is obtained and set aside. The rice husk is weighed and pl...

example 2

[0028] Mix soybean oil and 90% ethanol solution with a mass fraction of 10:3 into a three-necked flask with a stirrer and a thermometer, then put the three-necked flask into a water bath, and raise the temperature of the water bath to 65°C. Start the agitator, stir and mix at a speed of 350r / min for 35min to obtain a mixed solution; transfer the mixed solution into a separatory funnel, let stand at a temperature of 5°C for 4h, separate and obtain the upper oil phase and the lower ethanol phase respectively, Put the ethanol phase in the lower layer into a rotary evaporator, and concentrate it by rotary evaporation at 450°C for 35 minutes to obtain a concentrated solution for later use; mix the upper oil phase and activated sludge from a sewage plant at a mass ratio of 5:1 and put it into a fermenter. Seal the mouth of the tank and ferment for 8 days at 40°C. After the fermentation is over, the fermentation product is obtained and set aside. The rice husk is weighed and put into ...

example 3

[0030] Mix soybean oil and 90% ethanol solution with a mass fraction of 10:3 into a three-necked flask with a stirrer and a thermometer, then put the three-necked flask into a water bath, and raise the temperature of the water bath to 70°C. Start the agitator, stir and mix at a speed of 400r / min for 40min to obtain a mixed solution; transfer the mixed solution into a separatory funnel, let stand at a temperature of 6°C for 5h, separate and obtain the upper oil phase and the lower ethanol phase respectively, Put the ethanol phase in the lower layer into a rotary evaporator, concentrate by rotary evaporation at 50°C for 40 minutes, and obtain a concentrated solution for later use; mix the upper oil phase and activated sludge from a sewage plant at a mass ratio of 5:1 and put it into a fermenter. Seal the mouth of the tank and ferment for 9 days at 45°C. After the fermentation is over, the fermentation product is obtained and set aside. The rice husk is weighed and placed in a tis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com