Raw material pretreatment method for improving light performance of residual oil

A lightening and pretreatment technology, applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of lack of understanding of the degree of influence and the specific reasons for the impact, and difficulty in playing a theoretical guiding role, achieving low cost and simple methods. , the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Take 70g of Shengli decompression residue in the anti-permeation airtight bottle A, seal it, place it in the ultrasonic treatment instrument, set the processing temperature, processing power and ultrasonic time, and perform ultrasonic treatment after the temperature reaches the ultrasonic temperature;

[0041] (2) After the ultrasonic treatment is completed, take a certain amount of oil sample, and measure its average relative molecular mass, viscosity, residual carbon value, and density after ultrasonic treatment;

[0042] (3) Take 50g of Shengli decompression residual oil after ultrasonic treatment, and conduct autoclave hydrogenation experiments under certain conditions of specific rotation speed, hydrogen pressure, and operating temperature, and then analyze the composition of its hydrogenation products after treatment under certain conditions;

[0043] (4) Repeat the process (1)-(3) above for Shengli vacuum residue without ultrasonic treatment, and compare the obt...

Embodiment 2

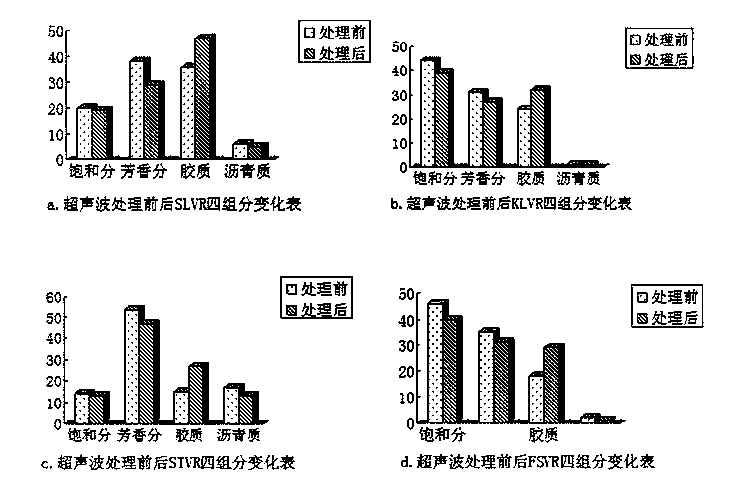

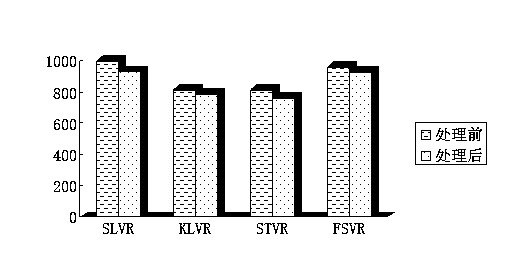

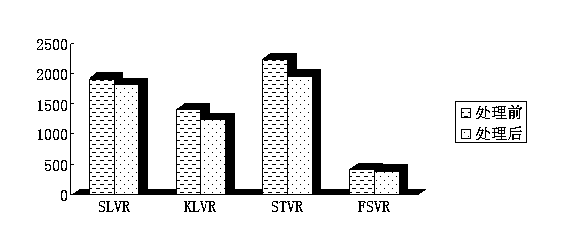

[0047] The preparation steps of this example are the same as Example 1, and the only difference from Example 1 is that the raw material used is Saudi light vacuum residue. After ultrasonic treatment, the properties of Shengli vacuum residue change significantly, and the hydrogenation effect is obviously improved:

[0048] The four-component analysis showed that: the saturated content decreased by 0.88 percentage points, the aromatic content decreased by 6.91 percentage points, the pectin increased by 11.62 percentage points, and the asphaltene decreased by 3.8 percentage points; the average relative molecular weight decreased by 5.99%, the viscosity decreased by 12.3%, and the residual The carbon value decreased by 21.3%, and the density was basically unchanged; the average molecular total carbon number decreased by 3.41, the aromatic carbon number decreased by 1.15, the total ring number decreased by 0.41, and the characteristic parameters of heavy oil increased by 0.04; the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com