Pretreatment method of residual oil hydrogenation raw material and residual oil hydrogenation method

A technology for residual oil hydrogenation and hydrogenation treatment, which is applied in the field of residual oil hydrogenation process and pretreatment of residual oil hydrogenation raw materials, and can solve the problems of difficult industrialization, less residual oil lightening performance pretreatment, etc. , to improve the dispersion state, reduce the average relative molecular weight, and increase the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

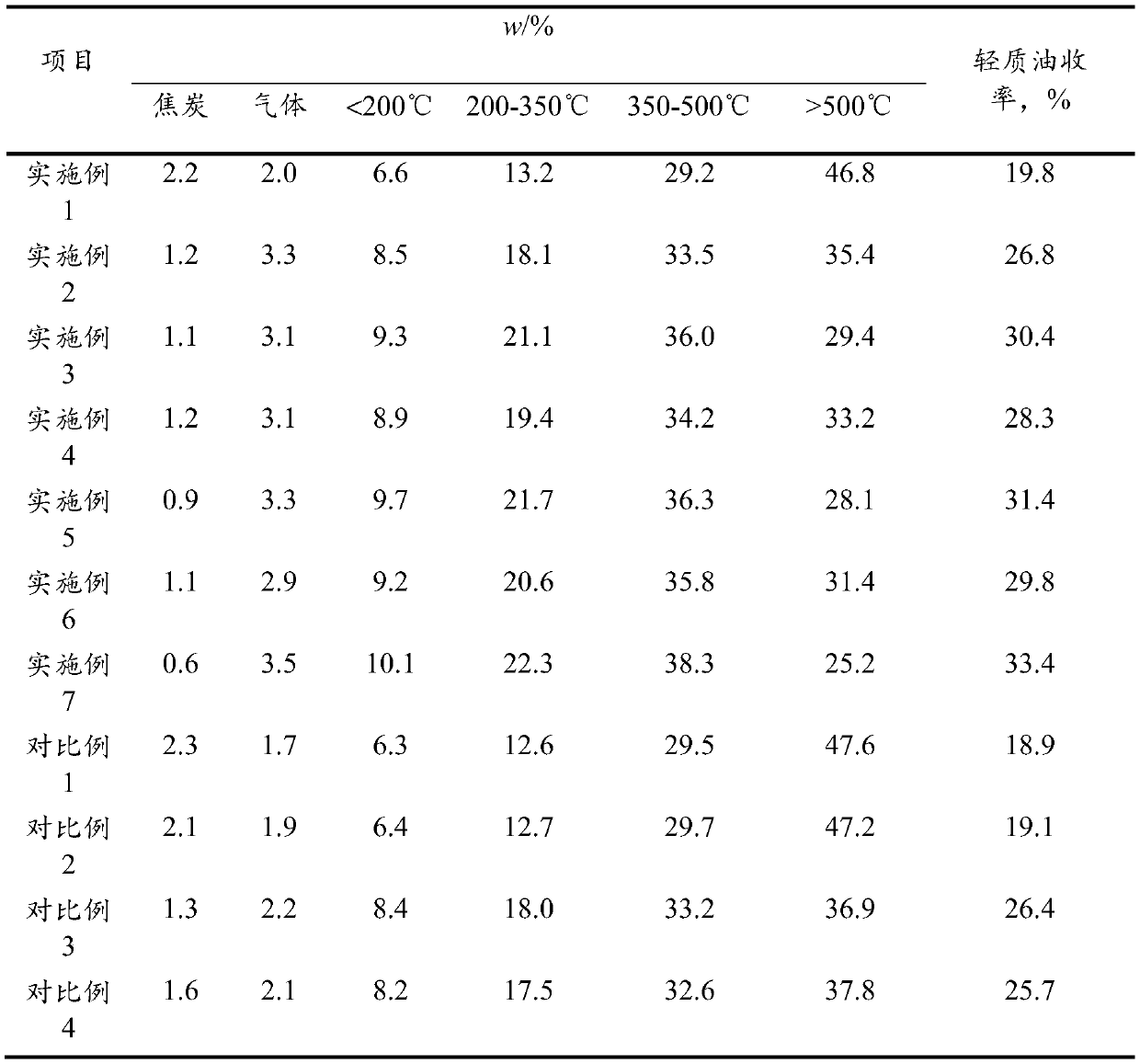

Examples

Embodiment 1

[0051] A kind of residual oil hydrogenation feedstock pretreatment method, comprises the following steps:

[0052] (a) preheating the vacuum residue at 100°C;

[0053] (b) carrying out mild hydrotreating to the preheated residual oil, the pressure of mild hydrotreating is 2MPa, the temperature is 300°C, and the time is 40min;

[0054] (c) Carrying out cavitation treatment to the residual oil after mild hydrotreating, the cavitation device used in the cavitation treatment is a Venturi tube type cavitation device; the temperature of the cavitation treatment is 90°C, and the pressure is 2MPa;

[0055] A method for hydrogenation of residual oil, comprising the following steps: hydrogenating the residual oil after cavitation treatment, the temperature of the hydrogenation reaction is 420° C., the pressure is 10 MPa, and the reaction time is 1.5 h.

Embodiment 2

[0057] A kind of residual oil hydrogenation feedstock pretreatment method, comprises the following steps:

[0058] (a) carry out gentle hydrotreating to residual oil, the pressure of gentle hydrotreating is 5MPa, temperature is 350 ℃, time is 20min;

[0059] (b) Cavitation treatment is carried out on the residual oil after mild hydrotreatment. The cavitation device used in the cavitation treatment is a throttling orifice cavitation device. The temperature of the cavitation treatment is 150° C. and the pressure is 4 MPa.

[0060] A method for hydrogenation of residual oil, comprising the following steps: hydrogenating the residual oil after cavitation treatment, the temperature of the hydrogenation reaction is 390° C., the pressure is 9 MPa, and the reaction time is 1.5 h.

Embodiment 3

[0062] A kind of residual oil hydrogenation feedstock pretreatment method, comprises the following steps:

[0063] (a) preheating the vacuum residue at 100°C;

[0064] (b) carrying out mild hydrotreating to the preheated residual oil, the pressure of mild hydrotreating is 2.5MPa, the temperature is 310°C, and the time is 25min;

[0065] (c) Cavitation treatment is carried out on the residual oil after mild hydrotreatment. The cavitation device used in the cavitation treatment is a throttling orifice cavitation device. The temperature of the cavitation treatment is 150° C. and the pressure is 20 MPa.

[0066] A method for hydrogenation of residual oil, comprising the following steps: hydrogenating the residual oil after cavitation treatment, the temperature of the hydrogenation reaction is 400° C., the pressure is 9 MPa, and the reaction time is 1.5 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com