A kind of cold rolling extremely thin plate rolling oil composition

A technology of composition and rolling oil, which is applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of general rolling cleanliness, failure to meet rolling production requirements, and pollute the environment, and achieve good oil burning resistance and rust prevention performance, good mill cleanability, high surface cleanliness

Active Publication Date: 2011-11-30

石家庄新泰特种油有限公司

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The rolling oil has good lubricity, but the rolling cleanliness is poor, and it cannot meet the requirement of bright annealing without degreasing treatment

The rolling oil has general lubricity and rolling cleanliness, and also cannot meet the requirement of bright annealing without degreasing treatment.

In short, the rolling oil based on grease is suitable for high-load and high-speed rolling. The most notable feature is its good lubricating performance. The existing problems are: first, the cleanliness of the rolling mill is poor, and a large amount of deposits are prone to appear around the rolling mill. It pollutes the environment, affects the appearance, and reduces work efficiency; secondly, without degreasing treatment after rolling, the annealing cleanliness is very poor, and the finished plate with excellent surface quality cannot be obtained

This type of rolling oil has excellent rolling mill cleanliness and annealing cleanliness. The surface of the steel plate that has not been degreased after annealing is clean and free of pollutants. production requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

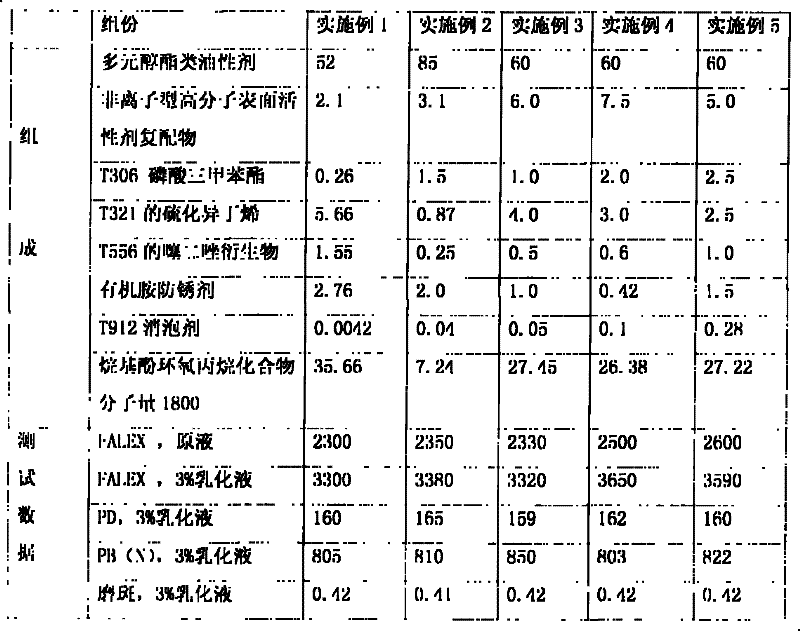

[0029] The present invention is described in detail below with specific examples, but the examples do not limit the scope of the present invention.

[0030]

[0031] Test data show that this type of product has excellent performance.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel cold rolling extreme thin plate rolling oil composition. Synthesized ester and an alkylphenol epoxypropane compound are compounded to be used as an oily agent and can form a layer of quite dense protective film on the surface of metal to form favorable annealing detergency and heat stability. A nonionic compounded emulsifying agent can increase the diameter of the elaioplast of emulsion and shows better lubricity by matching with the interaction of a metal passivator, a sulfur-containing extreme pressure antiwear agent, and the like.

Description

technical field [0001] The invention belongs to the lubricating composition for metal processing technology, in particular to a cold-rolled ultra-thin plate rolling oil composition Background technique [0002] With the increasing demand for cold-rolled sheets in the automotive industry and household appliances, the requirements for the surface quality of cold-rolled sheets are getting higher and higher, and the rapid development of cold-rolled equipment and related technologies has led to the current high-speed production of cold-rolled sheets. and large-scale production. These five-roll rolling equipment and four-roll and six-roll equipment put forward stricter requirements on the lubricity of rolling oil, mill cleanliness, annealing cleanliness, cycle stability, and the disposability of waste rolling oil. At present, most of the domestic market is occupied by foreign brands. Many domestic enterprises and scientific research institutes have conducted research on this typ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10N40/24C10N30/04

Inventor 丁峰周增强甄国芬李学兵丁浩周志刚周增位甄海超刘想刘龙

Owner 石家庄新泰特种油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com