Processing method and apparatus for converting heavy oil to light fractions

A processing method and technology of a processing device are applied in the field of lightweight processing methods and devices to achieve the effect of wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

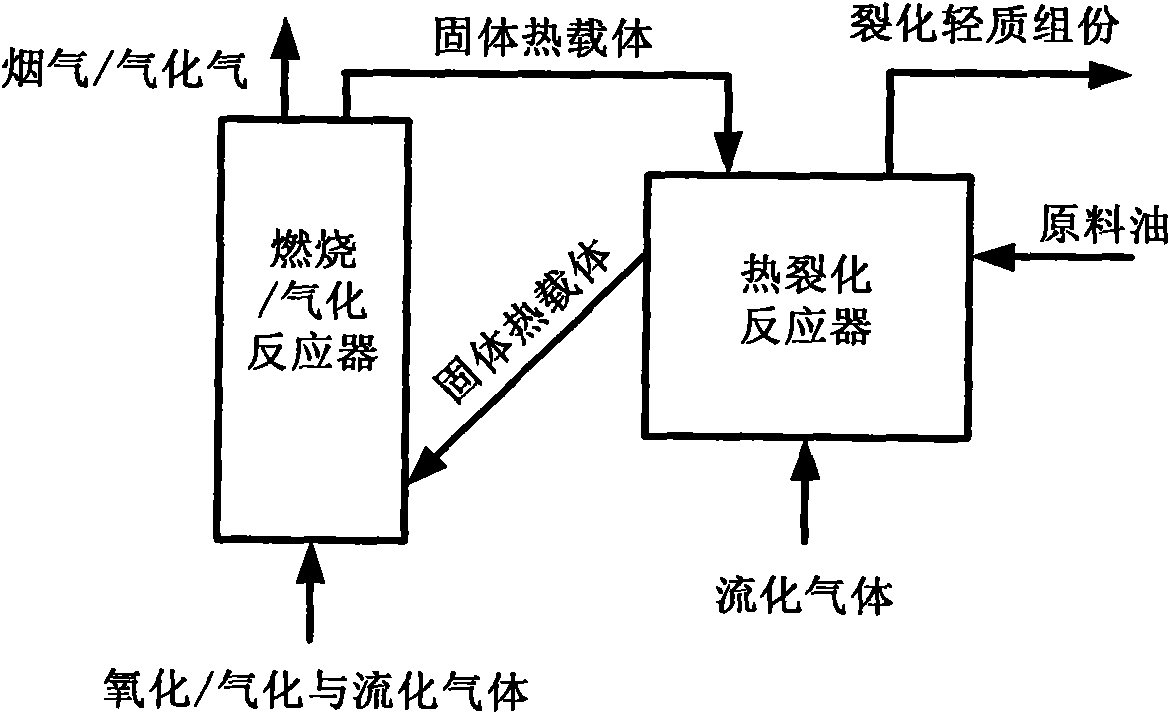

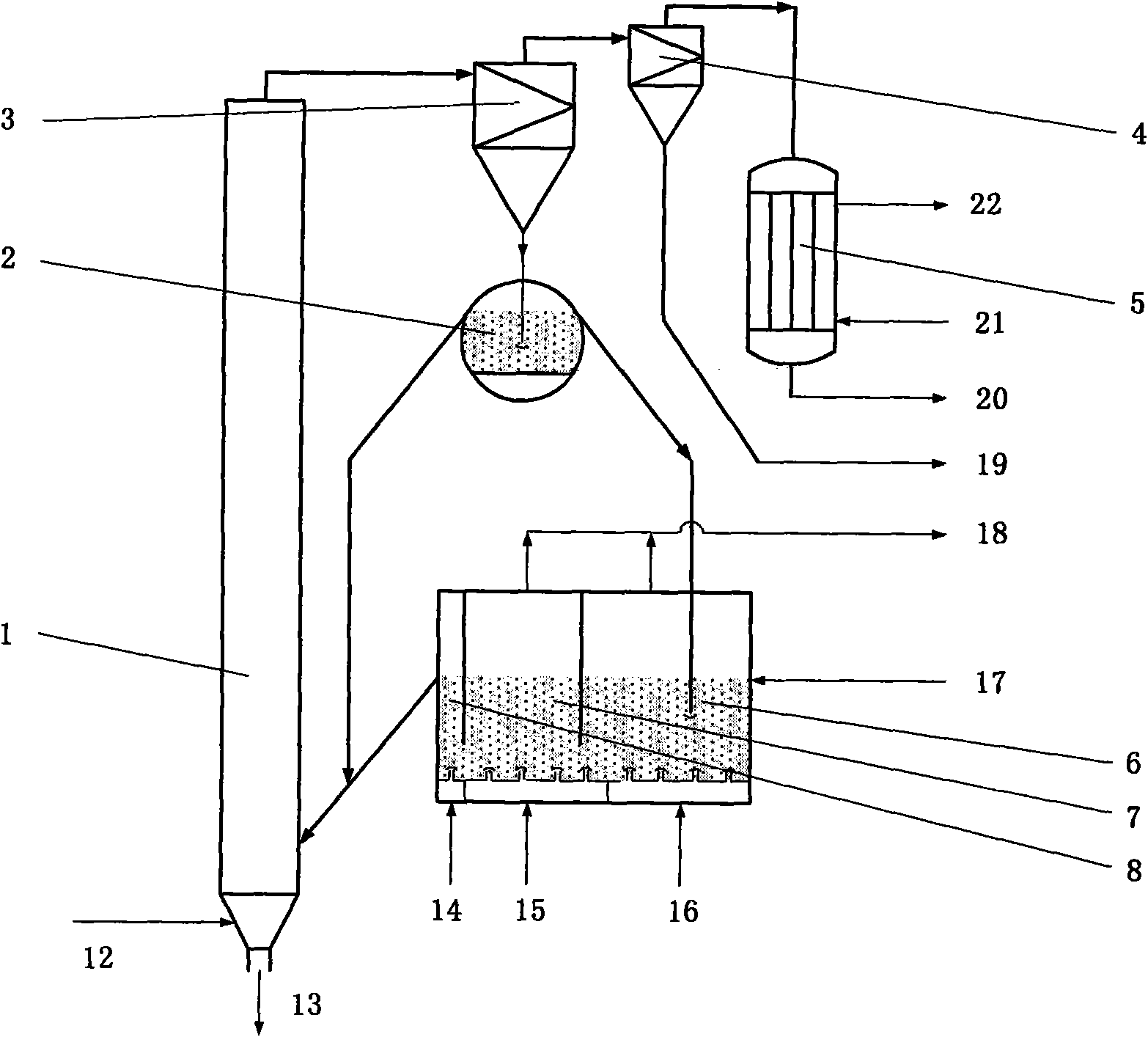

[0063] The specific implementation of the heavy oil lightening processing method is not only applicable to the conventional raw material oil used for catalytic cracking and hydrocracking, but also suitable for the processing of heavy or low-quality raw material oil with high sulfur, nitrogen, metal and residual carbon content processing, including figure 1 It is a schematic diagram of the principle of heavy oil lightening processing method, which embodies the basic principle of heavy oil lightening processing. figure 2 It is a schematic structural view of the device shown in Example 1. As can be seen from the figure, the heavy oil lightening processing device provided by the present invention includes:

[0064] The thermal cracking reaction chamber 6, the stripping chamber 7 and the material return chamber 8 connected to each other at the lower part; the lower part of the thermal cracking reaction chamber 6, the lower part of the stripping chamber 7 and the lower part of the ...

Embodiment 2

[0080] The difference between this embodiment 2 and embodiment 1 is: the riser type combustion / gasification reactor 1 in this device is mainly used for the gasification reaction of the coke produced by the thermal cracking reaction; The heat carrier enters the riser combustion / gasification reactor 1 used for gasification reaction after being stripped and returned. At this time, the bottom of the riser combustion / gasification reactor 1 is fed with oxygen-enriched fluidizing gas, The superficial gas velocity of the oxygen-enriched fluidized gas in the riser type combustion / gasification reactor 1 is 0.3-6m / s, and the gasification reaction temperature is 900-1200°C, so that the petroleum coke attached to the solid heat carrier The gasification reaction is completed during the fluidization lifting process.

Embodiment 3

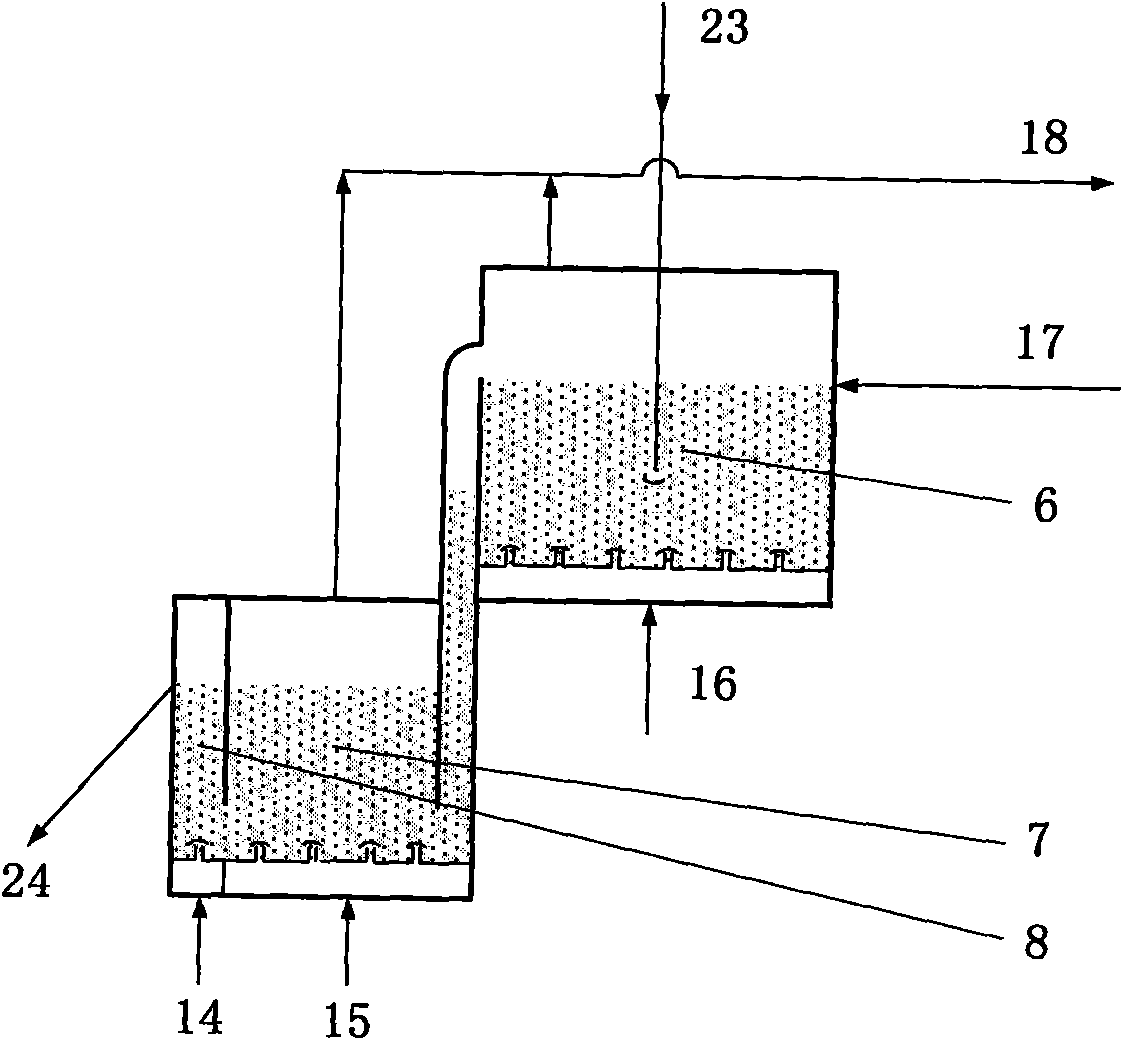

[0082] as attached image 3 As shown, the stripping chamber 7 and the return chamber 8 are integrally structured and arranged separately from the thermal cracking reaction chamber 6, and the material flowing out from the overflow port of the thermal cracking reaction chamber 6 enters the stripping chamber 7 in the form of a moving bed through a downcomer And the material return chamber 8, the downcomer can further play the role of material seal to prevent the air flow from being reversed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com