A method of producing gasoline with a high octane number from residual oil

A technology for high-octane gasoline and residual oil, which is applied in the fields of hydrocarbon oil treatment products, petroleum industry, and hydrocarbon oil treatment. Reaction performance and other issues, to achieve the effect of promoting hydrogenation to remove impurities, inhibiting carbon deposition, and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

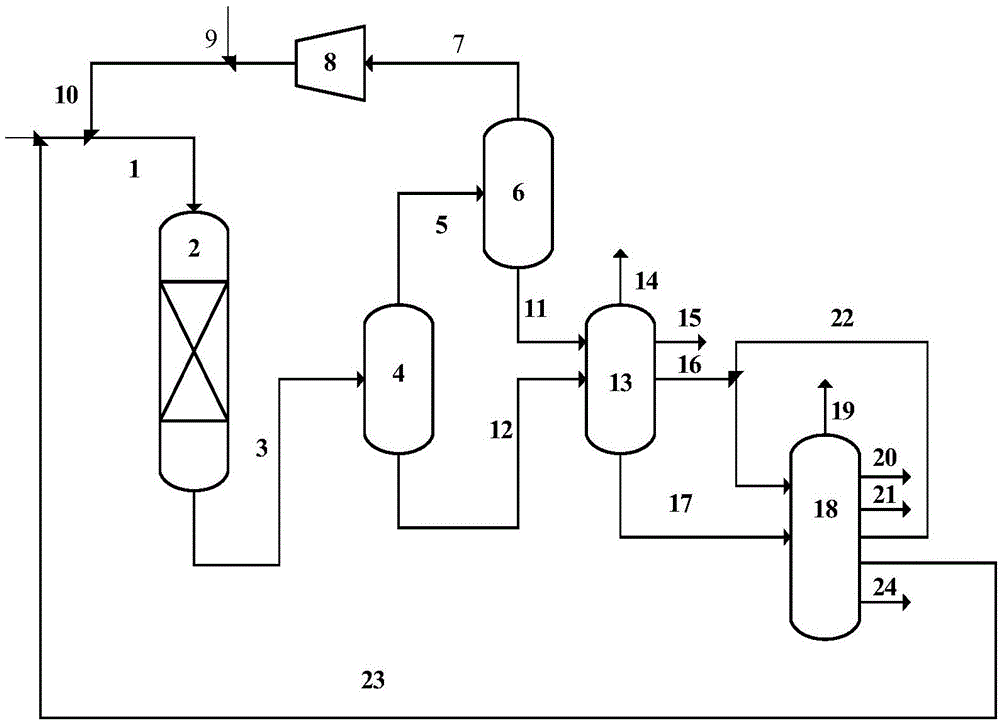

Method used

Image

Examples

Embodiment 1

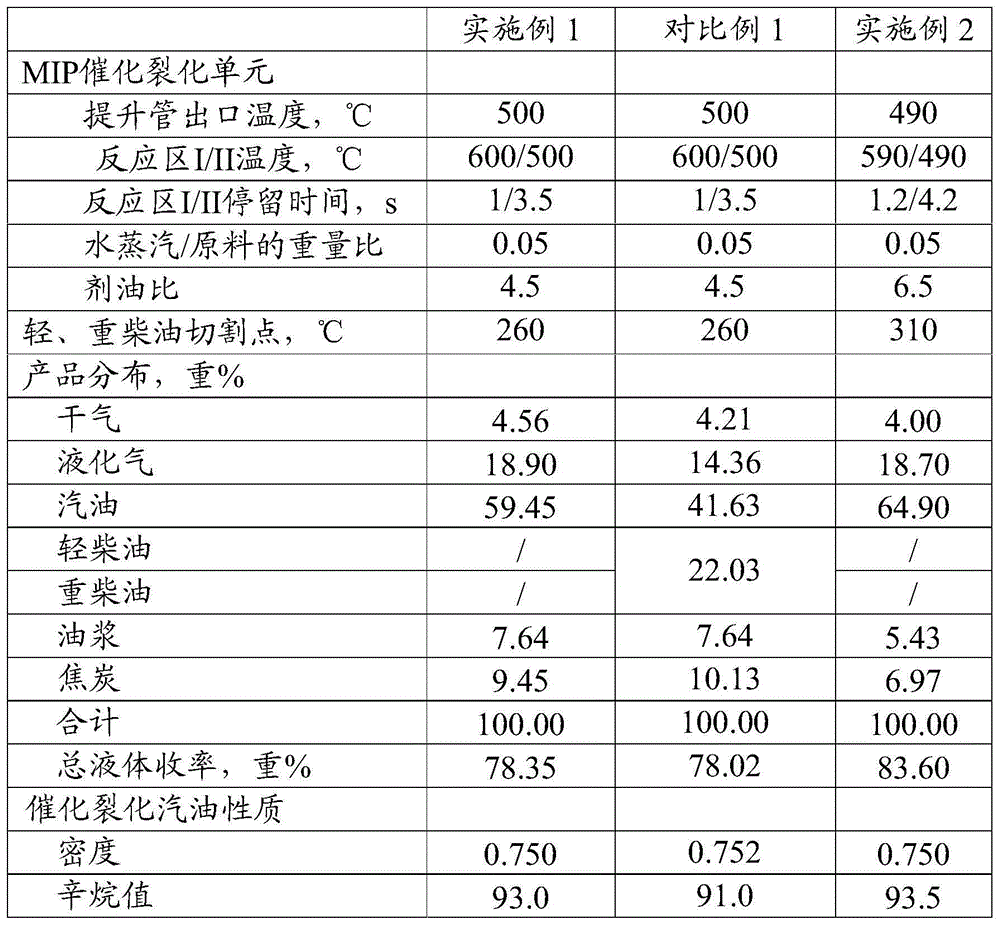

[0050] The heated residual oil raw material A and FCC heavy diesel oil are mixed with hydrogen and then enter the residual oil hydrogenation reactor to react under the action of the residual oil hydrogenation catalyst. The test conditions of the residual oil hydrogenation unit are shown in Table 2. The reactant flow enters the high-pressure separator and is separated into a gas-phase flow and a liquid-phase flow, wherein the gas-phase flow is recycled after being purified and boosted. Gas, gasoline, hydrogenated diesel and hydrogenated residue were obtained by fractional distillation of the liquid phase stream at normal pressure. The properties of the products are shown in Table 2. The hydrogenated residual oil is used as the raw material of the MIP catalytic cracking unit, and the cracking reaction is carried out in the presence of the catalytic cracking catalyst, and the reaction products are separated to obtain dry gas, liquefied gas, gasoline, light diesel oil, heavy diesel...

Embodiment 2

[0053] Embodiment 2 adopts residual oil raw material B. Process flow is identical with embodiment 1. The cut point of FCC light diesel oil and FCC heavy diesel oil is 310°C. The test conditions of the residual oil hydrogenation unit are shown in Table 2. See Table 3 for the test conditions of the FCC unit, product distribution and properties of FCC gasoline.

[0054] It can be seen from Table 3 that the yields of catalytically cracked gasoline are 59.45% and 64.90%, and the octane numbers are 93.0 and 93.5, respectively, using residual oil raw materials A and B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com