Ceramic initial blank forming method based on microwave in-situ sintering and product

A ceramic and in-situ technology, applied in the field of additive manufacturing, can solve the problems of low strength of the blank, easy to block the ink path and corrode the nozzle, etc., and achieve the effect of increasing the SiC content, reducing the amount of residual carbon and silicon, and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

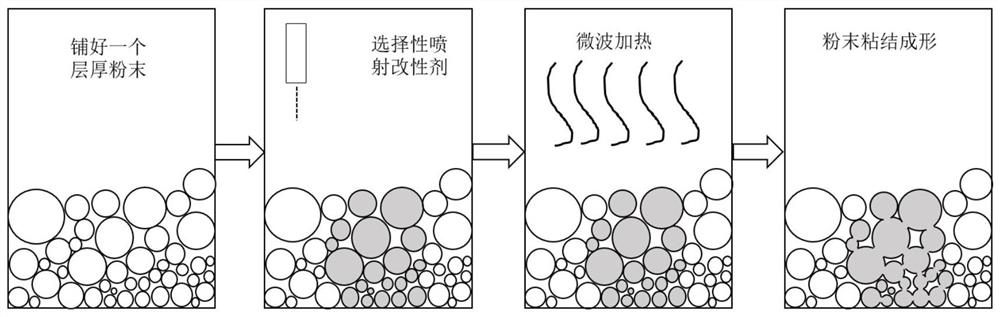

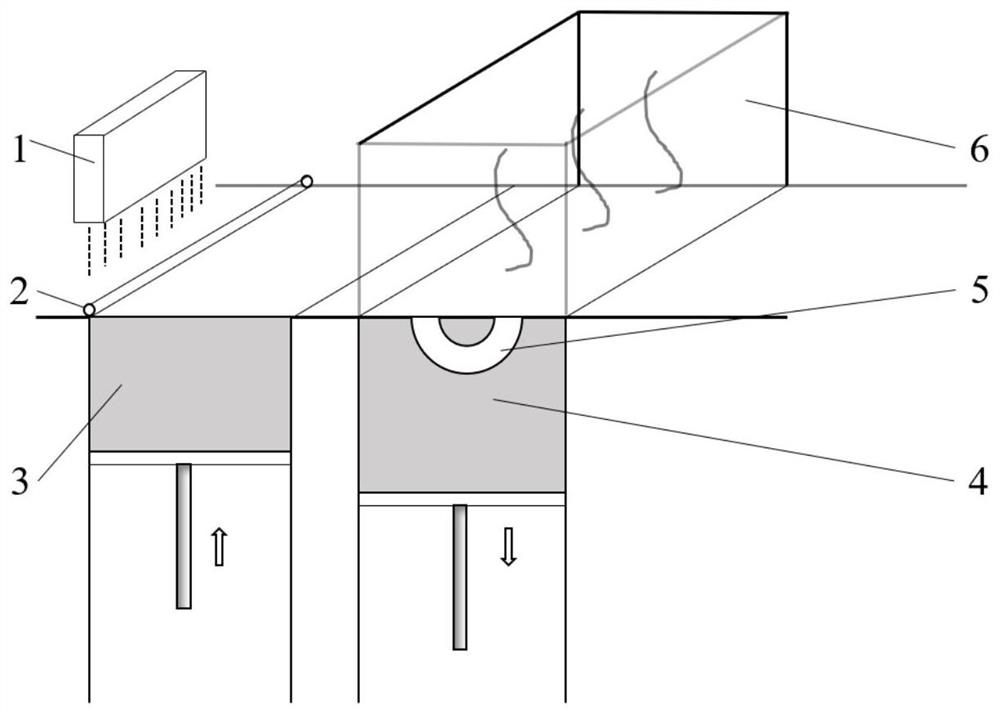

Method used

Image

Examples

Embodiment 1

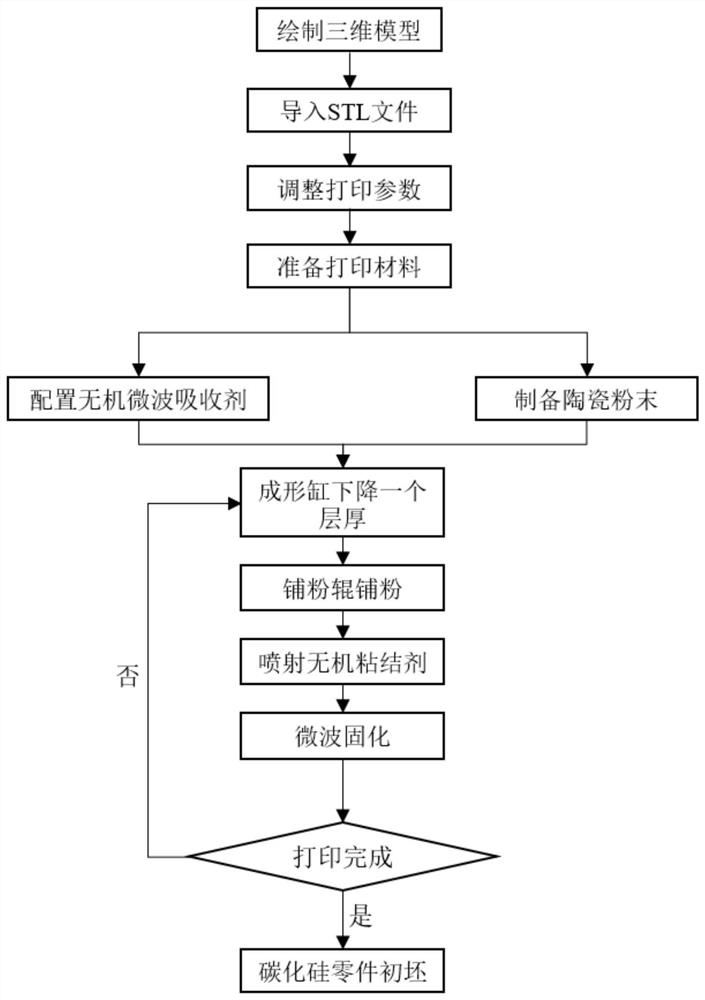

[0056] A method for forming silicon carbide ceramics based on microwave sintering and three-dimensional spray printing, comprising the following steps:

[0057] S1 To prepare a microwave absorber, take 75wt% deionized water, use a balance to take 25wt% iron nitrate powder, and take 0.5wt% glycerin.

[0058] Dissolve ferric nitrate powder and glycerin in deionized water, stir evenly to make it fully diffuse, measure the viscosity of the solution with a rotary gauge, measure the surface tension of the solution with a surface tension meter, and measure the acidity and alkalinity with a pH meter.

[0059] Add 0-0.5wt% acetic acid dropwise to adjust the pH of the microwave absorber;

[0060] The final solution binder has a viscosity of 1.3 mPa·s, a pH of 7.1, and a surface tension of 21 mN / m.

[0061] S2 is configured with silicon carbide powder particles, and α-SiC powders with a particle size of 50 μm and 10 μm are selected.

[0062] Measure with a graduated cylinder, mix 80vol...

Embodiment 2

[0065] A method for forming silicon carbide ceramics based on microwave sintering and three-dimensional spray printing, comprising the following steps:

[0066] S1 To prepare a microwave absorber, select 65wt% deionized water, use a balance to measure aluminum chloride powder with a mass fraction of 33.5wt%, and measure 1wt% glycerin.

[0067] Dissolve aluminum chloride powder and glycerin in deionized water, stir evenly to make it fully diffuse, measure the viscosity of the solution with a rotary gauge, measure the surface tension of the solution with a surface tension meter, and measure the acidity and alkalinity with a pH meter.

[0068] Add 0-0.5wt% acetic acid dropwise to adjust the pH of the microwave absorber;

[0069] The final solution binder has a viscosity of 1.65 mPa·s, a pH of 7.0, and a surface tension of 29 mN / m.

[0070] S2 is configured with silicon carbide powder particles, and α-SiC powders with a particle size of 50 μm and 10 μm are selected.

[0071] Mea...

Embodiment 3

[0074] A method for forming silicon carbide ceramics based on microwave sintering and three-dimensional spray printing, comprising the following steps:

[0075] S1 To prepare a microwave absorber, select 60wt% deionized water, use a balance to measure 38.5wt% aluminum chloride powder and 1.4wt% furfuryl alcohol.

[0076] Dissolve aluminum chloride powder and glycerin in deionized water, stir evenly to make it fully diffuse, measure the viscosity of the solution with a rotary gauge, measure the surface tension of the solution with a surface tension meter, and measure the acidity and alkalinity with a pH meter.

[0077] Add 0-0.1wt% acetic acid dropwise to adjust the pH of the microwave absorber;

[0078] The final solution binder has a viscosity of 1.83 mPa·s, a pH of 7.0, and a surface tension of 20 mN / m.

[0079] S2 is configured with silicon carbide powder particles, and α-SiC powders with a particle size of 50 μm and 10 μm are selected.

[0080] Measure with a measuring c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com