Treatment of industrial water systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

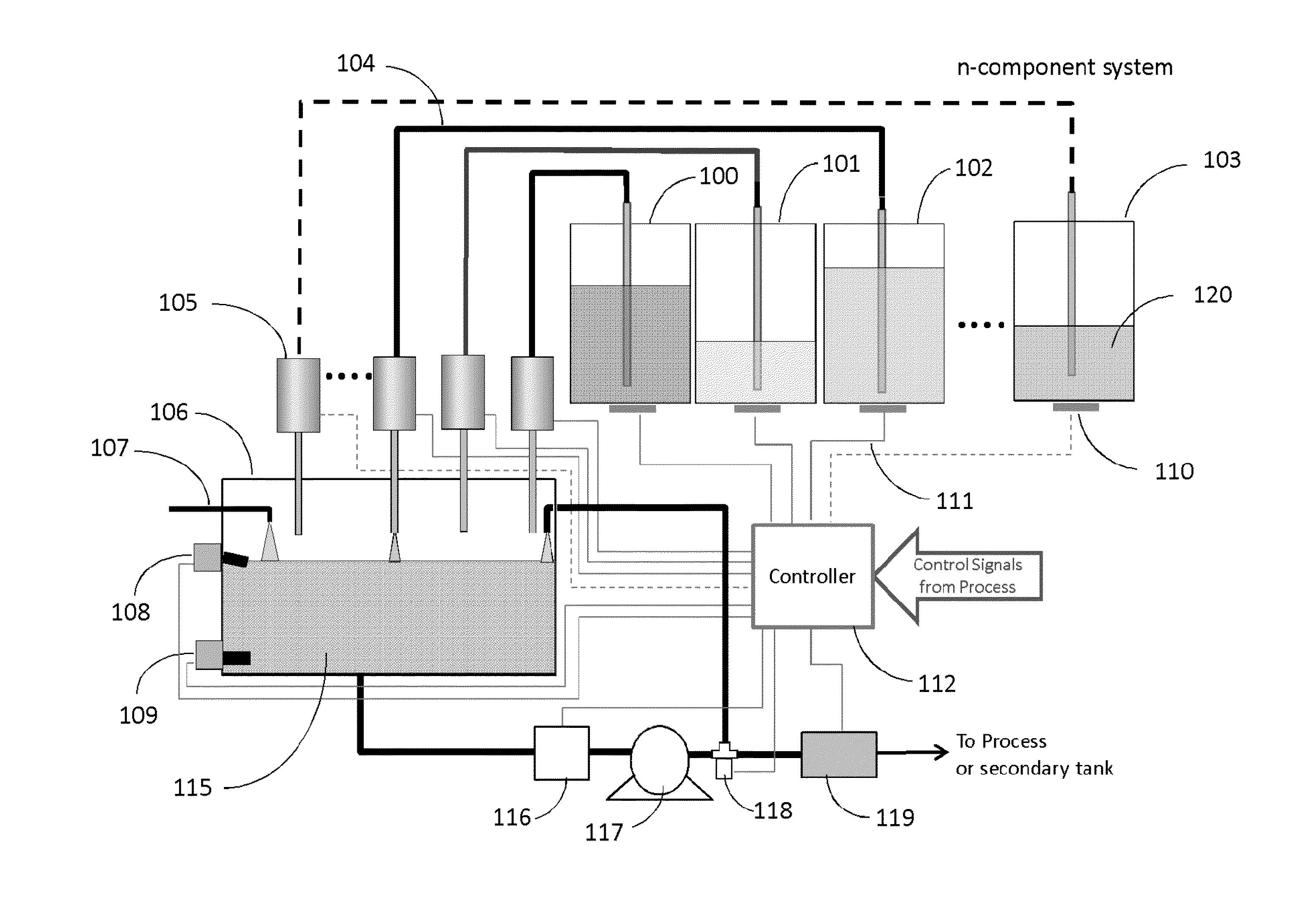

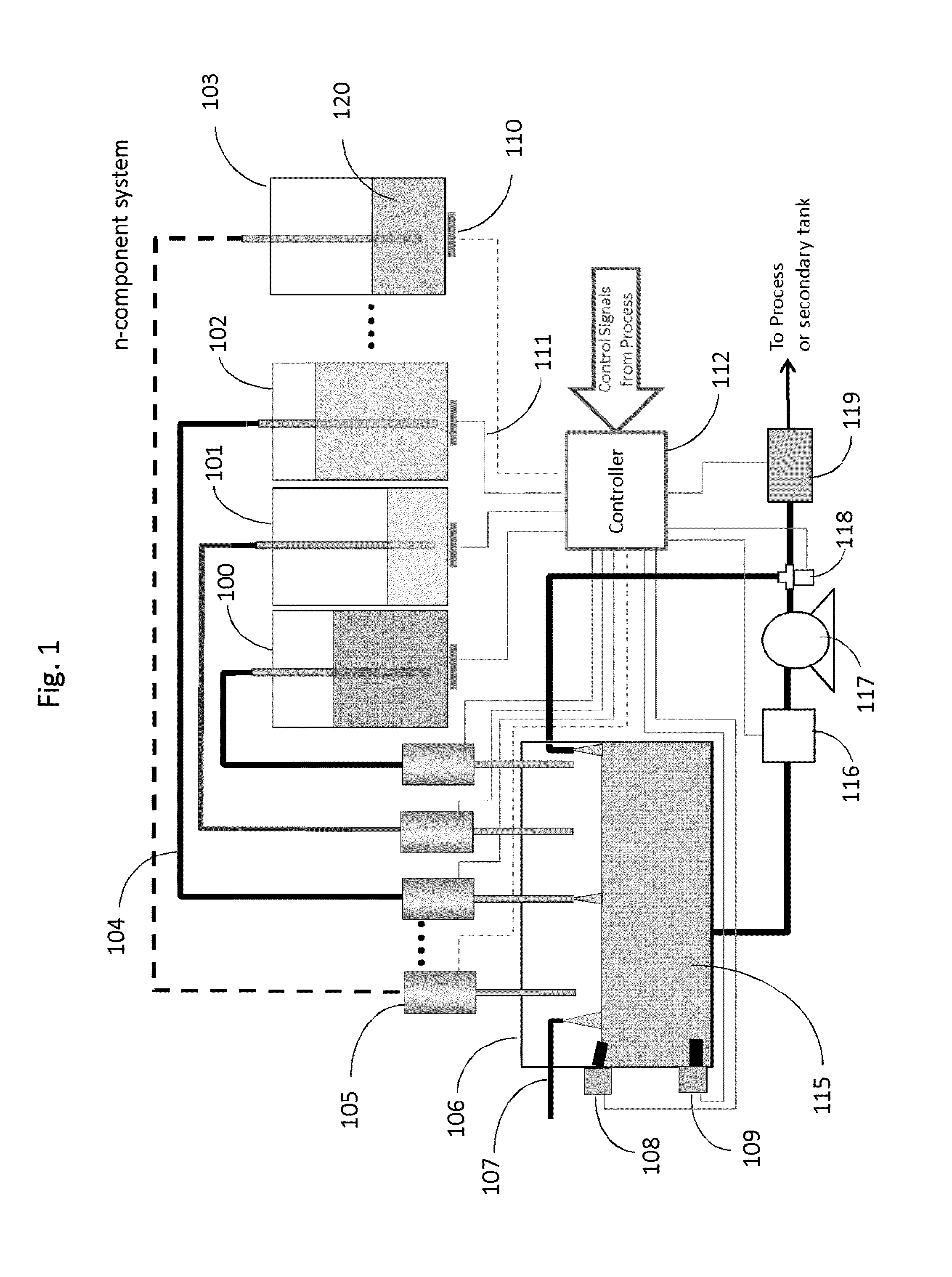

[0052]The first example illustrates injection of the additive package made up from a set of different actives blended in a holding vessel at a predetermined composition for a given batch. Once the additive package is made it can then be dispensed into the process stream. The composition of the additive package is adjusted during the blending step by controlling the individual actives dispensed to the holding vessel. A schematic layout is shown in FIG. 1 for an n-component delivery system. The concentrated actives used in formulating the blend are isolated from one another by containers 100, 101, 102, and n-container 103. The containers can be any suitable material either hard wall or flexible, e.g., polymer bag, that is chemically compatible with the concentrated active. The containers can be modular allowing the user to easily remove and replace the container with the same or different active component, thus providing added flexibility in the composition of the additive package. A ...

example 2

[0062]In the previous example, multiple component monitoring requires a fluorometer having different excitation source wavelengths and detection channels. An alternative approach of the invention is based on monitoring the fluorescence from one component during sequential steps of adding the different active components. For example, to construct the additive package listed in Table 1 the steps listed in Table 2 can be followed to make a 1.0-liter blend. Using THSP as the baseline fluorescence signal the additive package is constructed by measuring the change in the THSP signal. Because THSP is initially highly concentrated the fluorescence signal is nonlinear, as shown in FIG. 3 for the integrated intensity collected using a bifurcated fiber optic probe. For this example, one fiber optic leg supplies the excitation light at 365 nm that propagated through fiber and exits the probe which is submerged into the fluid. Light exiting the probe excites the THSP molecules resulting in fluor...

example 3

[0066]A third aspect of the invention is monitoring and controlling the amount of active added to the holding tank by monitoring fluorescence of a secondary fluorophore component, e.g., PTSA, blended with the concentrated active. The fluorescence from the PTSA monitored by fluorometer 116 (FIG. 1) provides a metric for the active concentration, since the proportion of PTSA to active is known. For example, to construct the additive package in Table 1, HEDP traced with PTSA, can be added first to the holding tank with additional dilution water to set a baseline fluorescent signal count representing a HEDP concentration of the target 11% value for a completed additive package. Controlling the concentration of the subsequent actives is then made by selectively adding or not adding PTSA to concentrated actives. In this case, if the second active added is THSP with no PTSA then the signal measured using the fluorometer tuned for PTSA monitoring will change. The amount of attenuation or ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com