System and method for softening treatment of desulfurization wastewater of coal-fired power plant

A technology for desulfurization wastewater and coal-fired power plants, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long chemical cleaning cycle, low chemical cleaning cost, high operating cost, etc. problem, to achieve the effect of reducing the operating cost of the agent, reducing the operating cost of the agent, and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with example the present invention is described in further detail:

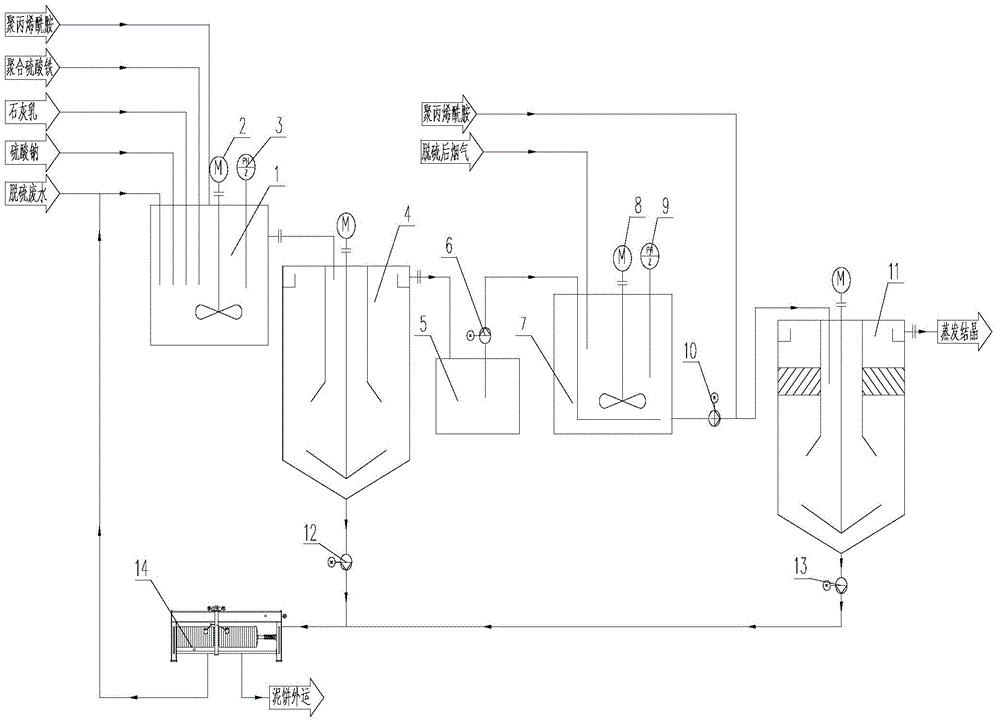

[0028] see figure 1 , the present invention comprises a primary reaction tank 1, a primary clarification tank 4, an intermediate water tank 5, a secondary reaction tank 7 and a secondary clarification tank 11, wherein the primary clarification tank 4 and the secondary clarification tank 11 have water outlets and sludge outlet, the outlet of the primary reaction tank 1 is connected with the inlet of the primary clarifier 4, the water outlet of the primary clarifier 4 is connected with the inlet of the intermediate water tank 5, and the outlet of the intermediate water tank 5 is connected with the inlet of the secondary reaction tank 7 connected, the outlet of the secondary reaction tank 7 is connected with the inlet of the secondary clarifier 11 through the secondary clarification feed water pump 10, and the water outlet of the secondary clarifier 11 discharges the treated water for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com