Desulfurization waste water zero discharging process and system

A desulfurization wastewater, zero-discharge technology, applied in gaseous discharge wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

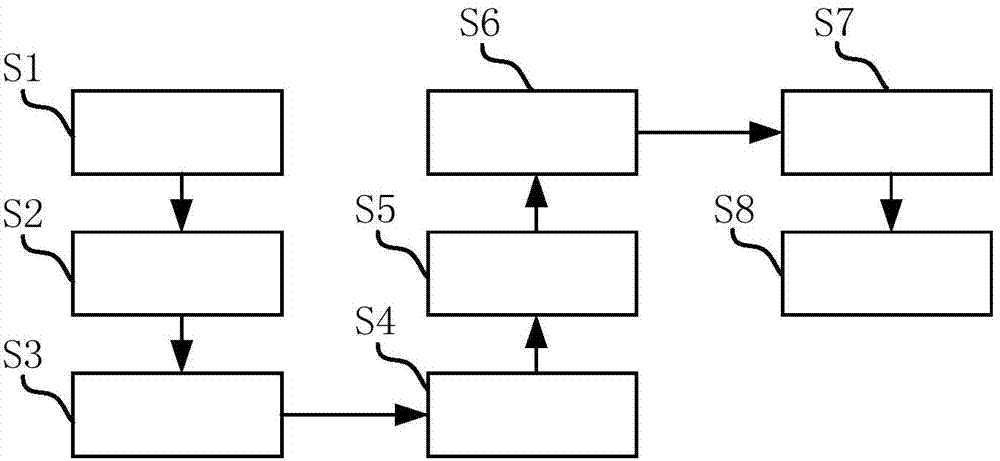

[0034] Embodiment 1 of the present invention: as figure 1 As shown, a zero-discharge process for desulfurization wastewater includes the following steps:

[0035] S1, adding sodium hydroxide to the desulfurization wastewater to remove divalent and trivalent scaling ions in the desulfurization wastewater;

[0036] S2, adding sodium carbonate to the desulfurization wastewater to remove calcium ions in the desulfurization wastewater;

[0037] S3, the solid-liquid separation of the desulfurization wastewater is carried out through the tubular ultrafiltration membrane, and the separated impurities are dehydrated and then discharged;

[0038] S4, further removing divalent and trivalent scaling ions in the desulfurization wastewater through a sodium ion exchanger;

[0039] S5, using the principle of nanofiltration to concentrate and reduce the desulfurization wastewater, and the separated solution containing divalent sulfate ions and cations is treated with a freezing denitrificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com