Technique for realizing ultralow emission of glass kiln smoke

A technology for glass furnace and furnace smoke, which is applied to the purification process of glass furnace smoke and the process field of ultra-low emission of glass furnace smoke, can solve the problems of easy sticking bags, easy back corona, high operating costs, etc. The effect of catalyst poisoning, improving dust removal efficiency and reducing corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

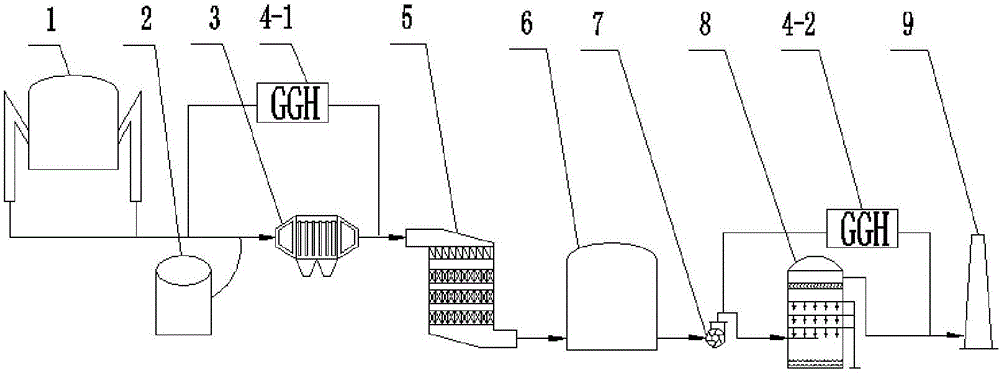

Image

Examples

Embodiment 1

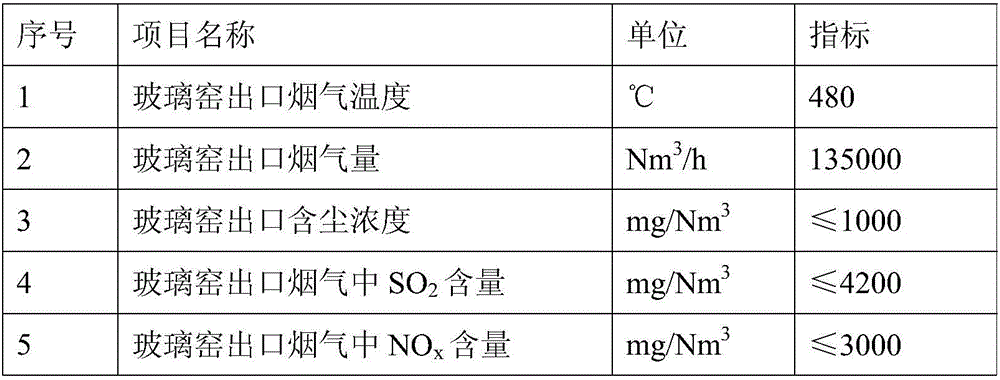

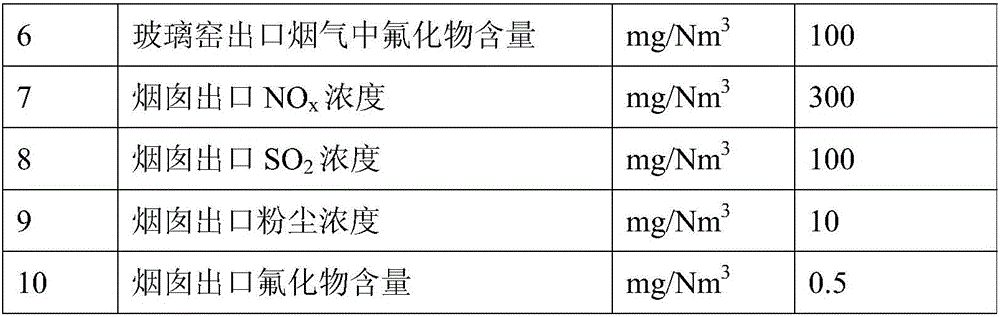

[0032] The specific flue gas conditions of the glass kiln project of the 650t / d production line fueled by petroleum coke are shown in the table below:

[0033]

[0034]

[0035] 480°C high-temperature furnace smoke at the outlet of a glass furnace, SO 2 The content is 4200mg / Nm 3 , NO x Content 3000mg / Nm 3 , dust concentration 1000mg / Nm 3 , fluoride concentration 100mg / Nm 3 , when the GGHⅠ effect drops to 230°C, when the bag is used for the first time and after each pulse cleaning, the active Al is sprayed by the powder adding device 2 o 3 powder, to coat the bags in the baghouse with Al 2 o 3 Powder, as anti-sticking agent. The powder injector is controlled by a solenoid valve, and Al is intermittently sprayed into the flue. 2 o 3 powder, the spoiler is set in the flue to make the flue gas and Al 2 o 3 The powder is mixed well. Fluoride in flue with Al 2 o 3 powder reaction while Al 2 o 3 After the powder is mixed with the flue gas, the viscosity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com